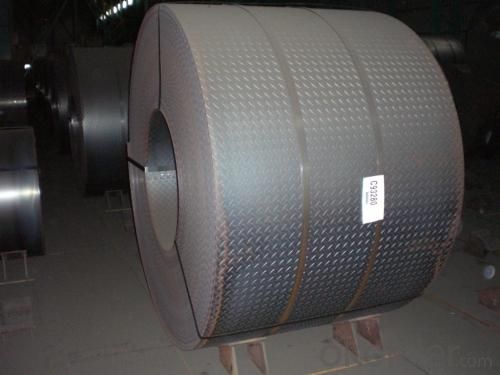

Hot- rolled steel coil for construction low hardness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

One, introduction

Edit

Hot rolled coil is used for continuous casting slab or slab as raw material, after reheating furnace heating, scales entered the roughing mill in the high pressure water, roughing cut is expected by the head, tail, and then enter the finishing mill, the implementation of the computer controlled rolling, finally after rolling through the laminar cooling (computer controlled cooling rate) and coiling machine coiling, become straight hair volume. Hair straightener roll head, tail often forms a tongue shape and fishtail, thickness, width of poor accuracy, edge has wavy, folding, tower and other defects. The volume weight heavier, steel coil diameter is 760mm. (general pipe industry like use. )

2 two, characteristics

Edit

Because there is no after annealing treatment, the hardness is very high (HRB greater than 90), mechanical processing performance is poor, only a simplebending process has less than 90 degree directional (direction perpendicular to the rolled).

3, use three

Edit

Hot rolled products with high strength and good toughness, easy processing and good forming can be excellent performance of welding, which is widely used in ships, cars, bridges, buildings, machinery, boiler, pressure vesselmanufacturing industry.

The scope of application:

(1) after annealing processing into the common cold;

(2) processing galvanized galvanized unit before the annealing treatment;

(3) the basic do not need to process the panel.

4 four, classification

Edit

Carbon steel plate, carbon plate, low alloy plate, ship plate, bridge plate, boiler plate, container plate etc.. Rolling hard volumes: under normal temperature,the hot pickling volumes of continuous rolling.

Hot rolled steel strip products include steel (roll) and the shear of steel plate.And steel (coils) can be divided into straight and finishes volume (the volume,smooth rolling and slitting roll).

- Q: How is steel wire rod used in the manufacturing of wire bins?

- Steel wire rod is used in the manufacturing of wire bins as it serves as the primary material for constructing the frame and structure of the bins. The steel wire rod is straightened, cut, and welded together to form the framework, providing strength and durability to the bin. Additionally, it can also be used to create the mesh or grid pattern that forms the sides and bottom of the bin, allowing for proper ventilation and visibility of the contents.

- Q: What are the different types of wire rods for reinforcement made from steel wire rod?

- There are several different types of wire rods for reinforcement made from steel wire rod, including plain wire rods, deformed wire rods, and cold-drawn wire rods. Plain wire rods are smooth and have no surface deformations, while deformed wire rods have ridges or bumps along their surface to provide better grip and adhesion with concrete. Cold-drawn wire rods are manufactured through a process of drawing the wire through a series of dies, resulting in a smoother and more uniform product with enhanced strength and flexibility.

- Q: How is a steel wire rod manufactured?

- A steel wire rod is manufactured through a process called hot rolling. It begins with heating a large steel billet in a furnace until it reaches a malleable temperature. The billet is then passed through a series of rolling mills, which gradually reduce its diameter and increase its length. This process is repeated multiple times to achieve the desired size and shape. Once the rod reaches its final dimensions, it is cooled, coiled, and then ready for further processing or usage in various industries.

- Q: What are the main factors affecting the market segmentation of steel wire rod?

- The main factors affecting the market segmentation of steel wire rod include the demand from various industries such as construction, automotive, and manufacturing, the quality and specifications required by different end-users, the geographical location and infrastructure of potential markets, the price competitiveness and availability of substitutes, and the evolving regulations and standards in the steel industry.

- Q: How is the steel wire rod market affected by changes in trade policies?

- Changes in trade policies can have a significant impact on the steel wire rod market. Trade policies, such as tariffs or import/export restrictions, can affect the supply and demand dynamics of steel wire rods. If a country imposes tariffs on imported steel wire rods, it can lead to a decrease in imports and an increase in domestic production. This can result in higher prices for steel wire rods within the domestic market. Conversely, if trade policies are liberalized, allowing for easier import and export of steel wire rods, it can increase competition and potentially lower prices. Therefore, changes in trade policies can influence the competitiveness and profitability of companies in the steel wire rod market.

- Q: What are the main factors affecting the market research of steel wire rod?

- The main factors affecting the market research of steel wire rod include supply and demand dynamics, price fluctuations, industry regulations, technological advancements, competitor analysis, and consumer preferences. Additionally, factors like raw material availability, production capacity, global economic conditions, and geopolitical events also play a significant role in influencing the market research of steel wire rod.

- Q: How is steel wire rod used in the production of wire shelves?

- Steel wire rod is used in the production of wire shelves as the main material. It is shaped and welded to create the frame and structure of the shelf, providing strength and stability. The wire rods are also used to create the horizontal and vertical wires that form the shelving surface, allowing for the storage and organization of various items.

- Q: What are the different surface treatments available for steel wire rod?

- There are several different surface treatments available for steel wire rods. Some common options include galvanizing, which involves applying a layer of zinc to protect against corrosion; phosphating, which creates a phosphate coating to enhance lubricity and improve paint adhesion; and copper coating, which provides electrical conductivity and corrosion resistance. Other treatments include chrome plating, nickel plating, and powder coating, each offering unique benefits depending on the intended application.

- Q: What are the main factors influencing the choice of steel wire rod order payment terms options?

- The main factors influencing the choice of steel wire rod order payment terms options can vary depending on various factors. Some of the key factors include: 1. Financial stability: The financial stability of both the buyer and the seller plays a significant role in determining the payment terms. If the buyer has a strong financial position, they may opt for more favorable payment terms such as deferred payment or letter of credit. Similarly, if the seller is financially stable, they may offer more flexible payment options to attract buyers. 2. Market competition: The level of competition in the steel wire rod industry also influences the choice of payment terms. If the market is highly competitive, sellers may offer more favorable payment terms to differentiate themselves and attract customers. Buyers, on the other hand, may negotiate for better payment terms to gain a competitive advantage. 3. Risk exposure: The level of risk associated with the transaction is another crucial factor. If there are higher risks involved, such as dealing with a new or unknown buyer/seller, payment terms may be more stringent to mitigate the risks. On the other hand, if the buyer-seller relationship is well-established and based on trust, more flexible payment terms may be agreed upon. 4. Cost of financing: The cost of financing also affects the choice of payment terms. If the cost of borrowing is high, buyers may prefer to negotiate for longer payment terms to manage their cash flow. Sellers, on the other hand, may prefer shorter payment terms to minimize their financing costs. 5. Trade regulations and customs: The payment terms can also be influenced by trade regulations and customs of the countries involved. Some countries may have specific requirements or restrictions on payment terms, such as mandatory letters of credit or advance payment. Compliance with these regulations and customs will influence the choice of payment terms. 6. Relationship and trust: The buyer-seller relationship and level of trust between the parties also play a significant role in determining the payment terms. If there is a long-standing relationship built on trust, more favorable payment terms may be agreed upon. Conversely, if there is a lack of trust or previous payment issues, more stringent payment terms may be imposed. In conclusion, the choice of steel wire rod order payment terms options is influenced by factors such as financial stability, market competition, risk exposure, cost of financing, trade regulations, and the relationship between the buyer and the seller. It is crucial for both parties to consider these factors and negotiate mutually beneficial payment terms that meet their respective needs and objectives.

- Q: What are the different types of packaging options available for steel wire rod?

- There are several different packaging options available for steel wire rod. The choice of packaging depends on factors such as the size and weight of the wire rod, its intended use, and the preferences of the buyer or manufacturer. One common packaging option for steel wire rod is coil packaging. In this method, the wire rod is coiled into a circular shape and then tightly wrapped with plastic or steel straps to secure it. Coils are often used for smaller diameter wire rods and are convenient for transportation and storage. Another packaging option is bundle packaging. In this method, several pieces of wire rod are bundled together and tightly bound with steel straps. Bundles are typically used for larger diameter wire rods and provide stability during transportation and handling. In addition to coils and bundles, steel wire rod can also be packaged in wooden crates or pallets. This method provides extra protection during transportation and can be used for both small and large diameter wire rods. Wooden packaging is often preferred when the wire rod needs to be shipped over long distances or stored for extended periods of time. Finally, some manufacturers may offer custom packaging options based on specific requirements. This could include special wrapping materials, additional protective measures, or unique packaging designs. Overall, the different types of packaging options available for steel wire rod ensure that the product is handled, transported, and stored in a safe and efficient manner, while also meeting the specific needs of the buyer or manufacturer.

Send your message to us

Hot- rolled steel coil for construction low hardness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords