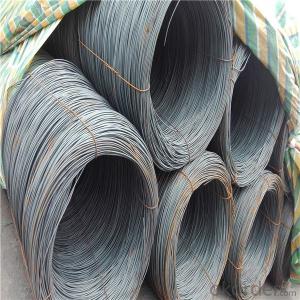

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality are durable, strong.packed and suitable for wire mesh,nail manufacture and construction

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SAE1006 SAE1008 SAE1010 SAE1012 SAE1016 SAE1018

Certificates: ISO, SGS, BV, CIQ

Weight per Coil:2-2.05tons

Packaging: Export packing, packed by coil

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: How many tons can be loaded into one 20ft container?

A4: Around 18—20tons

Q5: What is the chemical composition and physical properties of SAE1008?

A5:

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Images

- Q: How is steel wire rod used in the manufacturing of fences and meshes?

- Steel wire rod is commonly used in the manufacturing of fences and meshes due to its strength and durability. It serves as the primary material for constructing the framework and support structure of fences and meshes. The wire rod is typically formed into various gauges and sizes to meet specific requirements, and it is then woven or welded to create the desired pattern or design. This ensures that the fences and meshes are strong enough to withstand external forces, provide security, and effectively restrict access or contain objects within a designated area.

- Q: How are steel wire rods used in the production of fishing nets for catching fish?

- Steel wire rods are used in the production of fishing nets for catching fish as they provide strength and durability to the net structure. These rods are typically woven or twisted together to form the main framework of the net, ensuring it can withstand the weight and force of the fish caught. Additionally, the steel wire rods help maintain the shape and flexibility of the net, allowing for effective fishing operations.

- Q: What are the trade regulations for steel wire rod?

- The trade regulations for steel wire rod can vary depending on the country or region. However, some common regulations include import duties, quotas, and quality standards. It is important for exporters and importers to research and understand the specific regulations enforced by the relevant authorities before engaging in trade activities involving steel wire rod.

- Q: What are the alloying elements used in steel wire rod production?

- The alloying elements commonly used in steel wire rod production include carbon, manganese, silicon, and sometimes elements like chromium, nickel, and molybdenum for specific applications.

- Q: How does the corrosion resistance of steel wire rod vary with different coatings?

- The corrosion resistance of steel wire rod can vary significantly with different coatings. Coatings provide a protective barrier between the steel wire rod and its surrounding environment, preventing or slowing down the corrosion process. One commonly used coating for steel wire rod is zinc. Zinc coatings, such as hot-dip galvanizing or electro-galvanizing, create a layer of zinc on the surface of the steel wire rod. This zinc layer acts as a sacrificial anode, meaning it corrodes before the steel. As a result, the steel wire rod is protected from corrosion for a longer period. Zinc coatings are particularly effective in preventing rust and corrosion in outdoor or marine environments. Another popular coating for steel wire rod is epoxy. Epoxy coatings create a barrier between the steel wire rod and moisture or other corrosive substances in the environment. These coatings are often used in applications where the steel wire rod will be exposed to chemicals or harsh conditions that could accelerate corrosion. Epoxy coatings provide excellent resistance against chemicals, abrasion, and impact, making them suitable for various industrial and marine applications. Other coatings, such as polyethylene or polypropylene, can also be applied to steel wire rod to enhance corrosion resistance. These coatings are typically used in applications where the wire rod will be exposed to extreme temperatures or corrosive substances, such as in oil and gas pipelines. The polyethylene or polypropylene coatings act as a barrier, preventing moisture and chemicals from coming into contact with the steel wire rod, thereby reducing the risk of corrosion. In summary, the corrosion resistance of steel wire rod can vary depending on the type of coating applied. Zinc coatings provide sacrificial protection, epoxy coatings create a barrier against moisture and chemicals, and other coatings like polyethylene or polypropylene offer resistance to extreme conditions. The choice of coating depends on the specific application and the level of corrosion resistance required.

- Q: How is the weldability of steel wire rod evaluated?

- Different techniques and criteria are used to assess the weldability of steel wire rod. An important aspect in evaluating weldability is the chemical composition of the rod. The presence of certain elements, like carbon, sulfur, and phosphorus, can greatly affect how well the material can be welded. The mechanical properties of the wire rod, including tensile strength, ductility, and toughness, are also crucial considerations. These properties can impact the weld joint's quality and integrity. The surface condition of the wire rod is another factor that needs to be evaluated for weldability. Any contaminants or impurities on the surface can have a negative impact on the weldability and lead to defects. Moreover, the welding process and parameters used have a significant role in determining the weldability of the wire rod. Factors like heat input, welding speed, and selection of shielding gas need to be optimized to ensure proper fusion and minimize the risk of defects. Various tests and inspections are conducted to evaluate weldability. This includes visually examining the weld for defects such as cracks, porosity, or incomplete fusion. Non-destructive testing methods like ultrasonic testing or radiography can be used to detect internal flaws or inconsistencies. In addition, mechanical tests like tensile and bend testing are performed to assess the strength and ductility of the weld joint. These tests help determine the overall quality and performance of the welded wire rod. In conclusion, the weldability of steel wire rod is evaluated by considering factors such as chemical composition, mechanical properties, surface condition, welding process, and conducting tests and inspections to ensure the quality and integrity of the weld joint.

- Q: What are the key success factors for companies in the steel wire rod industry?

- Companies operating in the steel wire rod industry can achieve success by focusing on various key factors. To begin with, maintaining a strong emphasis on quality is essential. Steel wire rod is widely used in industries such as automotive, construction, and electrical, so it is crucial to maintain high-quality standards that meet the requirements of different applications. Additionally, companies in this industry should strive for a robust and efficient manufacturing process. This involves investing in modern equipment and technology to improve production efficiency, reduce costs, and enhance overall productivity. Continuous improvement in process optimization and waste reduction is also necessary to remain competitive. Another critical factor is establishing a well-diversified customer base. The steel wire rod market is highly competitive, and companies must have solid relationships with a diverse range of customers to ensure a steady demand for their products. Developing long-term partnerships with customers and understanding their specific needs and preferences are vital for maintaining a competitive edge. Furthermore, effective supply chain management is vital for success. Companies need to secure a stable and cost-effective supply of raw materials, such as steel billets, to ensure uninterrupted production. Additionally, maintaining good relationships with suppliers and implementing efficient logistics strategies are essential to minimize lead times and meet customer demands promptly. Moreover, a strong focus on innovation and research and development is crucial in this industry. Companies that invest in developing new products, improving existing ones, and exploring new applications for steel wire rod will gain a competitive advantage. This can involve collaborating with customers, research institutes, and industry partners to stay ahead of market trends and offer innovative solutions. Lastly, companies in the steel wire rod industry should prioritize sustainability and environmental responsibility. This includes implementing sustainable manufacturing practices, reducing carbon emissions, and minimizing waste generation. Given the growing demand for environmentally-friendly products, companies that adopt and promote sustainable practices will be better positioned for long-term success. In conclusion, key success factors for companies in the steel wire rod industry encompass quality control, efficient manufacturing processes, a diversified customer base, effective supply chain management, innovation, and sustainability. By focusing on these factors, companies can position themselves for growth and competitiveness in the market.

- Q: What are the major risks and uncertainties in the steel wire rod industry?

- The steel wire rod industry, like any other industry, faces several major risks and uncertainties that can impact its growth and profitability. Some of the key risks and uncertainties in the steel wire rod industry include: 1. Fluctuating raw material prices: Steel wire rod production heavily depends on the availability and cost of raw materials such as iron ore and coal. Any significant price fluctuations in these inputs can impact the industry's profitability and competitiveness. 2. Global economic conditions: The steel wire rod industry is highly sensitive to global economic conditions. During periods of economic downturns or recessions, demand for steel products, including wire rods, tends to decline. Uncertain economic conditions, trade tensions, and geopolitical factors can create volatility and affect the industry's growth prospects. 3. Overcapacity: Overcapacity is a significant concern in the steel wire rod industry. Excess production capacity leads to intense competition, price wars, and lower profit margins. This can be exacerbated by subsidized production in certain regions, leading to unfair competition and market distortions. 4. Technological advancements: The steel wire rod industry needs to constantly adapt to technological advancements to remain competitive. The adoption of advanced manufacturing technologies, automation, and digitalization can improve efficiency and reduce costs. However, the industry must also manage the risk of disruptions caused by technological changes and ensure a skilled workforce to operate and maintain these technologies. 5. Environmental regulations: The steel wire rod industry is subject to strict environmental regulations due to its significant carbon footprint and resource-intensive production processes. Compliance with emissions standards, waste management, and sustainable practices can present challenges and additional costs for industry players. 6. Currency fluctuations: Steel wire rod is a globally traded commodity, and currency fluctuations can impact the industry's competitiveness. A strong domestic currency can make exports more expensive, reducing demand and market share. Conversely, a weak domestic currency can make imports more expensive, affecting the cost of raw materials and machinery. 7. Trade barriers and protectionism: The steel wire rod industry is particularly susceptible to protectionist measures such as tariffs, quotas, and anti-dumping duties. Trade disputes and barriers between major steel-producing countries can disrupt global supply chains, increase costs, and limit market access. In conclusion, the steel wire rod industry faces several risks and uncertainties that require proactive management. Adapting to technological advancements, monitoring global economic conditions, managing raw material costs, complying with environmental regulations, and navigating trade barriers are crucial for industry players to maintain their competitiveness and long-term sustainability.

- Q: What are the common transportation methods for steel wire rod?

- The common transportation methods for steel wire rod include trucking, rail transport, and shipping via sea or inland waterways.

- Q: How is steel wire rod used in the manufacturing of wire mesh?

- Steel wire rod is used in the manufacturing of wire mesh as it serves as the primary raw material. The wire rod is drawn through a series of dies to reduce its diameter and increase its length, resulting in a thin and long wire. This wire is then woven, welded, or knitted together to create the wire mesh, which is widely used in various applications such as fencing, construction, and filtration systems.

Send your message to us

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords