Steel Wire Rods Hot Rolled Low Carbon Prime Quality Best Selling

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

Wire rod steel is widely used for commercial building structure, pre-engineering buildings, machinery support structures, prefabricated structure, medium scale bridges and so on. We have supplied this product for many years and gained widespread reputation.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

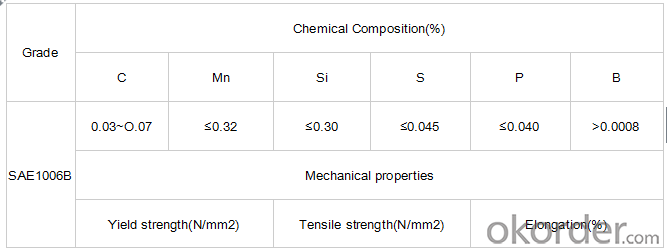

4.Wire Rod Steel for Construction Specification

5.FAQ of Wire Rod Steel for Construction

We have organized several common questions for our clients,may help you sincerely:

1.What is your minimum order quantity ?

Our MOQ is 500mt for each size. And we will consider to give more discount if you make big order like 10000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: What are the main components of steel wire rod production equipment?

- The main components of steel wire rod production equipment include the wire rod mill, which consists of a reheating furnace, roughing mill, intermediate mill, finishing mill, and cooling bed. Additionally, there are various auxiliary equipment such as descaling machines, shearing machines, coiling machines, and wire drawing machines that are integral to the production process.

- Q: What are the common material specifications for steel wire rod?

- The common material specifications for steel wire rod are typically determined by the specific requirements of the industry or application in which the wire rod will be used. However, there are some general material specifications that are commonly found in steel wire rod. One of the most important material specifications for steel wire rod is its chemical composition. Steel wire rod is typically made from carbon steel, which contains varying amounts of carbon and other alloying elements such as manganese, silicon, and sulfur. The exact composition of the steel wire rod will depend on the desired mechanical properties and the intended application. Another important material specification for steel wire rod is its size and shape. Steel wire rod is generally produced in coils with diameters ranging from a few millimeters to several centimeters. The specific size and shape of the wire rod will depend on the requirements of the end product, such as the desired strength, flexibility, and conductivity. Furthermore, the mechanical properties of the steel wire rod are also specified. These properties include the tensile strength, yield strength, and elongation, which determine the wire rod's ability to withstand forces and deformations without breaking. The mechanical properties are typically achieved through specific manufacturing processes and heat treatments. Other common material specifications for steel wire rod may include surface quality requirements, such as smoothness, cleanliness, and absence of defects. Additionally, certain industries or applications may have specific requirements for corrosion resistance, electrical conductivity, or thermal conductivity, which would also be specified. It is important to note that the exact material specifications for steel wire rod can vary significantly depending on the specific industry or application. Therefore, it is crucial to carefully review the requirements and consult industry standards or experts to ensure the appropriate material specifications are met for the intended use of the steel wire rod.

- Q: How is steel wire rod used in the manufacturing of wire forms for solar panels?

- Steel wire rod is used in the manufacturing of wire forms for solar panels as it serves as the base material for creating the intricate shapes and structures required. Using steel wire rod, manufacturers can bend, shape, and weld the wire to create the framework and support structures for the solar panels. This ensures durability and strength, allowing the panels to withstand various environmental conditions and securely hold the photovoltaic cells in place.

- Q: What are the common production processes for nickel-coated steel wire rod?

- The common production processes for nickel-coated steel wire rod include cleaning and pickling the steel rod, pre-coating it with a layer of copper to enhance adhesion, passing it through a nickel plating bath to deposit a layer of nickel, and finally, subjecting it to heat treatment to improve the coating's properties.

- Q: What are the common warranty considerations for steel wire rod?

- The common warranty considerations for steel wire rod typically include factors such as the quality of the material, compliance with industry standards, and the intended use of the rod. Other considerations may include the manufacturing process, any specific certifications or testing conducted, and the seller's reputation or track record in the industry. It is important to thoroughly review the warranty terms and conditions provided by the manufacturer or supplier to ensure that they meet the specific requirements and expectations for the steel wire rod.

- Q: What are the different types of steel wire rod coatings used for high-temperature resistance?

- Various coatings are utilized to ensure high-temperature resistance for steel wire rods. These coatings aim to safeguard the rods from oxidation, corrosion, and other types of damage that may arise at elevated temperatures. One prevalent coating used for high-temperature resistance is zinc. Zinc coatings offer exceptional protection against corrosion at high temperatures and are commonly employed in situations where the steel wire rods will be exposed to extreme heat. Another frequently used coating for high-temperature resistance is aluminum. Aluminum coatings can endure high temperatures and act as a barrier against oxidation and corrosion. Moreover, there exist specialized coatings specifically designed to withstand high temperatures. These coatings often incorporate materials like ceramic, refractory metals, or silicone-based compounds. Ceramic coatings, for instance, are renowned for their ability to endure extremely high temperatures and provide outstanding thermal insulation. Refractory metal coatings, such as tungsten or molybdenum, are utilized in applications where the steel wire rods will face extremely high temperatures and harsh environments. Silicone-based coatings are recognized for their heat resistance and can offer a protective shield against oxidation and corrosion. The selection of the appropriate coating relies on the specific application and the desired level of high-temperature resistance. Factors such as the operating temperature, the environment, and the required level of protection should be carefully considered when choosing a coating for steel wire rods used in high-temperature applications.

- Q: What are the common production processes for silicon-coated steel wire rod?

- The common production processes for silicon-coated steel wire rod typically involve cleaning and pickling the steel wire rod, applying a silicon coating through a continuous casting process, and then cooling and coiling the coated wire rod.

- Q: How is steel wire rod used in the production of wire strands for offshore oil and gas structures?

- Wire strands used for offshore oil and gas structures depend on steel wire rods, which are a vital component. These wire strands consist of multiple steel wires twisted together to create a durable and robust cable. The production process starts with inspecting the steel wire rods for quality and removing any defects. Then, the rods undergo a series of heat treatments to enhance their strength and flexibility. This involves heating the rods to high temperatures and rapidly cooling them through quenching. Quenching improves the mechanical properties of the steel wire rods, making them suitable for the challenging conditions found in offshore environments. After heat treatment, the steel wire rods are drawn through dies to reduce their diameter to the desired size. This wire drawing process ensures that the resulting wire strands have the necessary tensile strength and dimensional accuracy. Once the desired diameter is achieved, the steel wire rods are further processed to form wire strands. Specialized machines twist multiple steel wires together to create a strand with a specific number of wires and lay angle. The lay angle determines the flexibility and strength of the wire strand, which is crucial for offshore applications where high loads and harsh conditions must be endured. The resulting wire strands receive various surface treatments, such as galvanization or coating, to protect against corrosion and ensure longevity in offshore environments. These treatments provide additional protection, allowing the wire strands to withstand exposure to seawater, chemicals, and other corrosive elements commonly encountered in offshore oil and gas structures. Finally, the wire strands are cut to the required lengths and assembled into larger cable structures, such as wire ropes or umbilicals. These cable structures play a vital role in supporting and securing infrastructure within offshore oil and gas structures, ensuring stability and integrity even in extreme conditions. In conclusion, steel wire rod is a crucial element in producing wire strands for offshore oil and gas structures. Through a series of processes, including heat treatment, wire drawing, and twisting, steel wire rods are transformed into strong and durable wire strands capable of withstanding harsh offshore conditions. These wire strands are integral components in constructing and maintaining offshore oil and gas structures by providing stability, support, and protection against corrosion.

- Q: How is the ductility of steel wire rod evaluated?

- The ductility of steel wire rod is typically evaluated by conducting a tensile test. This test involves subjecting a sample of the steel wire rod to a controlled pulling force until it breaks. During the test, the elongation or deformation of the sample is measured, which gives an indication of the ductility of the material. Ductility is quantified by determining the percentage of elongation or reduction in cross-sectional area before the sample fractures. A higher percentage of elongation or reduction in cross-sectional area indicates greater ductility, while a lower percentage suggests lower ductility. This evaluation method allows manufacturers and engineers to assess the suitability of steel wire rod for various applications, such as in construction, automotive, or manufacturing industries.

- Q: How is steel wire rod used in the manufacturing of wire rope slings for marine applications?

- Steel wire rod is a crucial component in the manufacturing of wire rope slings for marine applications. These slings are extensively used in various marine industries, including shipping, offshore oil and gas, and fishing. To begin with, steel wire rod serves as the raw material for wire rope slings. It is typically made from high-quality carbon or alloy steel, which ensures the strength and durability required for marine applications. The steel wire rod is usually produced in a continuous casting process, resulting in a long, cylindrical shape. Once the steel wire rod is obtained, it undergoes a series of manufacturing processes to transform it into wire rope slings. The first step involves drawing the steel wire rod through a die to reduce its diameter and increase its length. This process is repeated multiple times to achieve the desired wire diameter. The drawn wire is then cleaned to remove any impurities or surface contaminants. Next, the cleaned wire is twisted together to form strands. The number of strands can vary depending on the desired strength and load capacity of the wire rope sling. These strands are then tightly wound around a central core, which provides stability and support to the wire rope. The final step in the manufacturing process is the application of protective coatings to enhance the wire rope sling's resistance to corrosion and wear. Marine environments are highly corrosive due to the presence of saltwater, which can lead to the degradation of steel. Therefore, coatings such as galvanization or zinc plating are commonly applied to the wire rope to provide a barrier against corrosion. Once the steel wire rod has been transformed into a wire rope sling, it is ready for use in various marine applications. Wire rope slings are used for a wide range of purposes, including lifting heavy loads, securing cargo, and towing vessels. They are known for their high strength, flexibility, and resistance to abrasion, making them ideal for demanding marine environments. In conclusion, steel wire rod plays a vital role in the manufacturing of wire rope slings for marine applications. It serves as the raw material for wire rope production, undergoes various manufacturing processes, and is ultimately transformed into a strong and durable sling. Wire rope slings made from steel wire rod are essential tools in the marine industry, providing reliable and safe lifting and securing capabilities.

Send your message to us

Steel Wire Rods Hot Rolled Low Carbon Prime Quality Best Selling

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords