Hot Rolled Stainless Steel Coil Made in China/ Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specifications of Stainless Steel Coil:

| commodity | 304 Stainless Steel Coil | ||||||||

| Width | 100mm to 2500mm or customized | ||||||||

| Thickness | 0.3mm-80mmor as customer's request | ||||||||

| surface | 2b, Ba, No. 1, No. 8, 8k, Mirror | ||||||||

| material | 201 202 304 301 302 321 347H 316 316L 309 310 430etc | ||||||||

| grade | 200/300/400 series | ||||||||

| standards | AISI ASTM JIS SUS and GB | ||||||||

| certifications | ISO 9001 SGS BV | ||||||||

| applications | Kitchenware, utensils, tableware, household appliances, construction decoration and daily products | ||||||||

| packing | Seaworthy wooden pallet or according to client's requirement | ||||||||

| Place of origin | Shanxi China (mainland) | ||||||||

| Payment terms | L/C or T/T | ||||||||

| Delivery time | Up to order quantity | ||||||||

Chemical Composition

Grade | Chemical Composition | ||||

C | Si | Mn | P | S | |

Q345B | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.040 | ≤0.040 |

Q345C | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.035 | ≤0.035 |

Q345D | ≤0.18 | ≤0.55 | 1.00-1.60 | ≤0.030 | ≤0.030 |

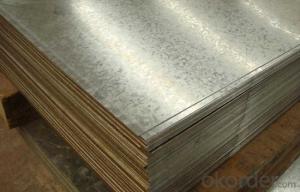

Product Picture

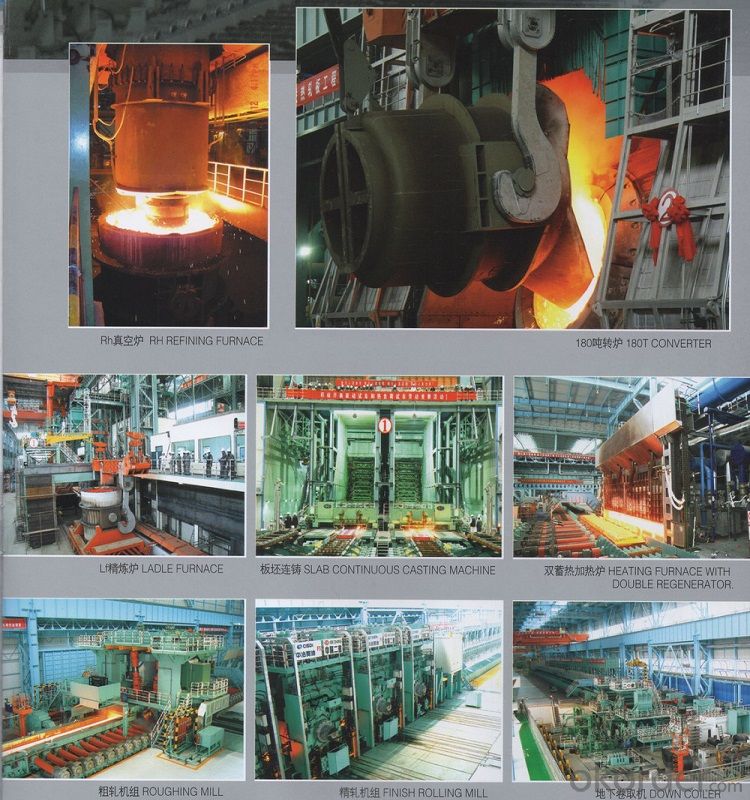

Production Process

Features:

Q195~Q345 hot rolled plate has low chemical composition and high-intensity, i.e. C and Mn content lower than that of all similar products at the same intensity level in China, high-performance products can be produced with low chemical composition. The specific hot-rolled process as per carbon equivalent will help improve the precision of product size and bring about high hit rate. Goods can be delivered as steel plates, steel coils and slitting strips to meet different needs of users.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- Once you LEARN how to play a guitar.. you will know just how stupid that question sounded. CLASSICAL guitars use NYLON STRINGS and ACOUSTIC guitars use STEEL STRINGS and either type of string will make your fingers sore until you get some ca louses on them

- Q: What are the different types of steel coil handling systems?

- There are several types of steel coil handling systems, including overhead crane systems, coil grab systems, coil transfer cars, and coil tilters. Each system is designed to efficiently and safely handle steel coils in different environments and applications.

- Q: How are steel coils used in the production of metal roofing?

- Steel coils are used in the production of metal roofing by being fed through a series of machines that shape, cut, and coat the steel to create the final roofing product. The coils are uncoiled and flattened, then formed into the desired profile using roll forming machines. The formed sheets are then cut into specific lengths and coated with protective layers to enhance durability and corrosion resistance. These coated steel sheets are then packaged and shipped to construction sites for installation as metal roofing.

- Q: how many persent of manganese in all types of carbon steel

- No problem with other answers but there is a high carbon/manganese steel called Hadfields Steel which has been used as armour plate in pilots seats in fighter aircraft in the second world war.This steel contains about 13% manganese and about 1.5 % carbon and is non-magnetic because it retains it's high temperature crystal type(austenite).When it is stuck with a bullet it absorbs the energy of the strike by changing crystal structure to the magnetic form of iron(in this case shock Martensite),I should think that it still has a role in the scoops and picks in earth-moving and farming blades.Well you did ask about all types of carbon steel!

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as structural components, including beams, columns, and trusses. They are also used for roofing and cladding systems, as well as in the fabrication of reinforcing bars and precast concrete elements. Additionally, steel coils are utilized in the manufacturing of pipes, tubes, and sheet metal products, serving as a crucial material in the construction industry.

- Q: How are steel coils used in the production of steel tanks?

- Steel tanks rely on steel coils as a vital element in their production. These coils, typically made from top-notch steel, act as the primary raw material for manufacturing steel tanks. The initial step involves unrolling and flattening the steel coils, which are usually supplied in a coiled form from the steel mills. Once unrolled, the coils are then cut into specific lengths and widths, depending on the desired dimensions of the steel tank. These cut pieces are molded and shaped into various tank components, including the cylindrical body, top and bottom ends, and additional fittings or accessories. The strength and durability of the tank heavily depend on the steel coils, ensuring its ability to withstand the demands of its intended use. The quality of the steel used in the coils is pivotal as it determines the tank's resistance to corrosion, pressure, and external forces. Additionally, employing steel coils enables efficient and cost-effective manufacturing of steel tanks. The standardized nature of the coils ensures consistent quality and dimensions, streamlining the production process. Precise cutting of the coils also minimizes waste and maximizes material utilization. Furthermore, steel coils offer design flexibility and customization options. They are easily formed and welded into intricate shapes, accommodating tanks of varying sizes, capacities, and configurations. This versatility makes steel coils the ideal choice for producing tanks across diverse sectors, including industrial, commercial, and residential applications. In conclusion, steel coils play a critical role in steel tank production. They provide the necessary raw material for manufacturing different tank components, guaranteeing strength, durability, and customization. By utilizing steel coils, manufacturers can efficiently produce high-quality tanks that meet the specific requirements of various industries.

- Q: What are the common packaging methods for steel coils?

- The common packaging methods for steel coils include wooden pallets, steel strapping, and protective wrapping such as shrink wrap or stretch film. Additionally, steel coils are often secured with steel bands or wire ties to ensure stability during transportation and storage.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- find an online tuner and tune the strings to the tuning you want. trust me, guitar hurts your fingers after a while. but your skin gets used to it's, it's what ever.

- Q: For my homework we have to fill out a table, but I cannot find some basic uses of these types of steel anywhere:Low carbon steel (iron mixed with lt;0.25% carbon)High carbon steel (iron mixed with lt;1.5% carbon)Stainless steel (iron mixed with nickle an chromium)Titanium steel (iron mixed with titanium)Manganese steel (iron mixed with manganese) Thanks :)

- Low okorder / You say you cannot find there uses anywhere. These all came up using the simplest of web searches. You really need to have a word with your IT teacher as clearly you are not doing basic searches properly.

- Q: How are steel coils inspected for uniformity?

- To ensure uniformity, steel coils undergo a series of visual and mechanical tests. First, the coil's external appearance is carefully examined for any visible defects like dents, scratches, or rust. This is crucial to maintain the coil's integrity and prevent potential issues during further processing. Next, non-destructive testing techniques such as ultrasonic or magnetic particle inspection are used to measure the coil's thickness at various points. This helps identify any variations in thickness that could affect the overall quality and performance of the coil. Precise instruments are also employed to measure the coil's width and ensure it adheres to the required specifications. This is important for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. Weighing scales or load cells are typically used for this purpose, ensuring consistent weight that meets the required standards. For internal inspection, steel coils may undergo eddy current testing, a non-destructive method that detects surface and near-surface defects. By utilizing electromagnetic induction, this technique can identify irregularities in the metal, such as cracks, voids, or inclusions. In summary, a comprehensive combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures thorough inspection for uniformity in steel coils. These rigorous processes guarantee the quality and reliability of the coils, enabling them to meet industry standards and customer requirements.

Send your message to us

Hot Rolled Stainless Steel Coil Made in China/ Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords