Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

Products Details

Diameter(mm) | Φ6 ,Φ8,Φ10,Φ12,Φ13,Φ14,Φ16,Φ18,Φ20,Φ22,Φ25,Φ28,Φ32, |

Length(m) | Unfolded / Straight Bundles weighing upto 2 Metric Tons and lengths is 6 Meters upto 15 Meters or according customers require |

U Shaped folded Bundles weighing up to 2 Metric Tons and lengths is 12 Meters | |

Rounded Coils ~ up to 2 Metric Ton Coils for Bending / Cutting Machine use. | |

Standard | GB(HRB335/HRB400/HRB500); |

BS4449 -1997 GRADE 250B, 460B; BS4449-2005 GRADE 500B; | |

ASTM A615 GRADE 40,GRADE60,GRADE75; ASTM A706; | |

DIN488-1 420S/500S, BST500S | |

JIS G3112 SD35, SD40, SD50,SD390 | |

NFA 35016 FE E 400, FE E 500 | |

CA 50/60 | |

GOST A3 R A500C | |

Surface finished | Screw-thread |

Epoxy coating | |

Galvanized coating | |

Production facility | Imports of production equipment from Italy |

Production capacity | 50,000 MT/month |

Payment term | T/T or 100% L/C at sight |

Package | By bundles. One bundles about 2-3tons |

Weight

------------------------------------------------------------------------------------------------------------------

| Dia mm | Theoretical weight kg/m | Dia mm | Theoretical weight kg/m |

| 12 | 0.888 | 25 | 6.85 |

| 14 | 1.21 | 28 | 4.83 |

| 16 | 1.58 | 29 | 5.06 |

| 18 | 2.00 | 32 | 6.31 |

| 19 | 2.235 | 36 | 7.99 |

| 20 | 2.47 | 40 | 9.87 |

| 22 | 2.98 | 50 | 15.42 |

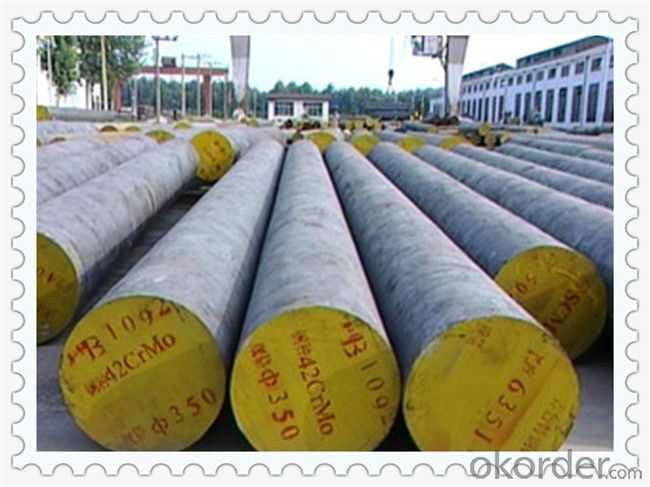

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

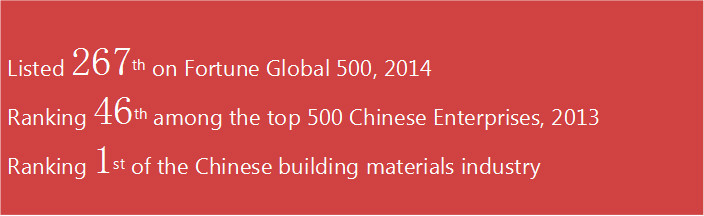

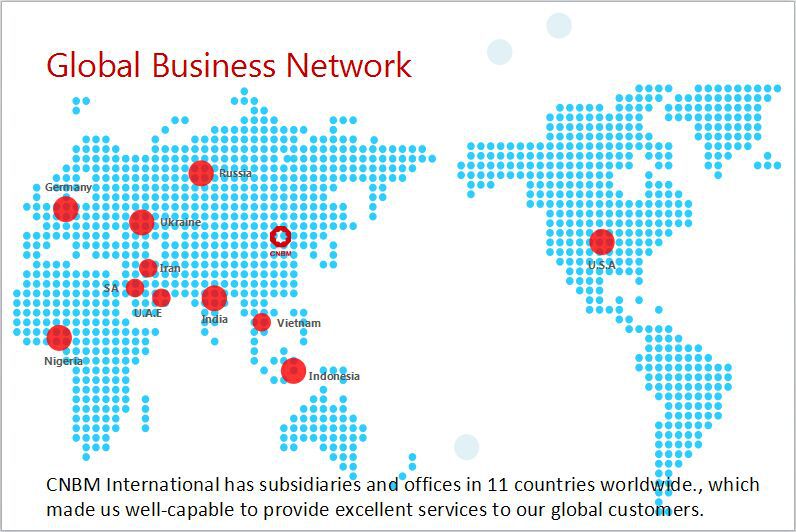

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Are steel round bars resistant to fire?

- Yes, steel round bars are highly resistant to fire. Steel is a non-combustible material and has a high melting point, making it suitable for use in high-temperature environments.

- Q: Can steel round bars be used in the manufacturing of appliances?

- Yes, steel round bars can be used in the manufacturing of appliances. Steel is a durable and versatile material that can be shaped into different forms, including round bars, which can be used for various purposes in appliance manufacturing such as structural support, handles, or components.

- Q: Can steel round bars be used for making tools or machinery parts?

- Yes, steel round bars can be used for making tools or machinery parts. Steel round bars are commonly used in the manufacturing industry due to their high strength, durability, and ability to withstand heavy loads. They can be machined, forged, or welded into various shapes and sizes to create different tools and machinery parts.

- Q: What is round steel?

- Round steel is a solid strip of steel whose cross section is round. Its specifications are expressed as millimeters in diameter. For example, "50" means a round steel with a diameter of 50 millimetersRound bar is divided into three kinds of hot rolling, forging and cold drawing. The specification of hot rolled round bar is 5.5-250 millimeters. Among them, 5.5-25 rounds of small round bars are mostly supplied by straight strips. They are commonly used as reinforcing bars, bolts and various mechanical parts;

- Q: What is the typical lead time for manufacturing steel round bars?

- The typical lead time for manufacturing steel round bars can vary depending on several factors, such as the quantity and size of the bars, the complexity of the manufacturing process, and the availability of raw materials. However, a general estimate for lead time could range from a few weeks to a couple of months. It is always best to consult with the specific manufacturer for an accurate timeframe.

- Q: Can steel round bars be used in the production of musical equipment?

- Yes, steel round bars can be used in the production of musical equipment. Steel is a strong and durable material that is commonly used in the construction of various musical instruments. Steel round bars can be utilized to create structural components such as frames, braces, and supports for instruments like guitars, drums, and pianos. Additionally, steel can be used to manufacture sound-enhancing elements such as resonators or bellows in certain instruments. The versatility and reliability of steel make it a suitable choice for musical equipment production.

- Q: Can steel round bars be used for making electrical components?

- No, steel round bars are not typically used for making electrical components. Electrical components are typically made from materials that have good electrical conductivity, such as copper or aluminum.

- Q: Can steel round bars be used for making gates?

- Yes, steel round bars can be used for making gates. Steel round bars are strong and durable, making them suitable for gate construction. They can be welded together to create a sturdy gate frame, and can also be used for decorative elements or as pickets. Additionally, steel round bars can be easily customized and shaped to fit the desired gate design.

- Q: What are the different types of steel alloys used for round bars?

- Round bars can be made from various steel alloys, each possessing unique characteristics that make them suitable for different purposes. Some commonly used steel alloys for round bars are as follows: 1. Carbon Steel: The most prevalent type of steel alloy for round bars, carbon steel is primarily composed of carbon and iron. It offers exceptional strength and toughness, making it ideal for applications in construction, manufacturing, and general engineering. 2. Stainless Steel: This alloy incorporates chromium, which grants it excellent resistance to corrosion. Consequently, stainless steel round bars are extensively utilized in the food and beverage industry, as well as in marine and chemical sectors where rust or oxidation is a concern. 3. Alloy Steel: This steel alloy is produced by adding elements like manganese, nickel, or chromium to enhance its mechanical properties. Alloy steel round bars are renowned for their high strength, hardness, and resistance to wear and tear. As a result, they find widespread use in automotive, aerospace, and machinery industries. 4. Tool Steel: Tool steel alloys are specifically engineered to possess remarkable hardness, wear resistance, and toughness. They are employed in the production of cutting tools, dies, and molds. Tool steel round bars are available in different grades, such as D2, O1, and A2, each offering specific properties for distinct applications. 5. Duplex Steel: This alloy combines austenitic and ferritic stainless steels, resulting in a blend of high strength and corrosion resistance. Duplex steel round bars are preferred in applications where both strength and resistance to corrosion are essential, such as in the oil and gas industry. These examples demonstrate the diversity of steel alloys used for round bars. The choice of a specific alloy depends on the desired properties and the intended application of the round bar.

- Q: What is the difference between hot rolled and cold rolled steel round bars?

- Hot rolled and cold rolled steel round bars differ in their production process and resulting characteristics. Hot rolled steel round bars are made by heating billets or ingots to a high temperature and then shaping them into the desired form using rolling mills. This process results in a scaled surface and a relatively rough texture. Hot rolled steel round bars have a wider tolerance and are not as precise in terms of their dimensions. They are generally used in applications where precision is not critical, such as construction and general manufacturing. On the other hand, cold rolled steel round bars are manufactured by cooling down hot rolled steel to room temperature and then further processing it through cold rolling mills. This process results in a smoother surface and a more precise dimension. Cold rolled steel round bars have a tighter tolerance and are commonly used in applications where precision is crucial, such as automotive components, machinery parts, and tools. In terms of mechanical properties, hot rolled steel round bars generally have a lower tensile strength and yield strength compared to cold rolled steel round bars. Cold rolled steel also tends to have a higher hardness and a more uniform grain structure, which can enhance its strength and durability. Overall, the main difference between hot rolled and cold rolled steel round bars lies in their production process, surface finish, dimensional accuracy, and mechanical properties. The choice between the two depends on the specific requirements of the application and the desired characteristics of the end product.

Send your message to us

Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords