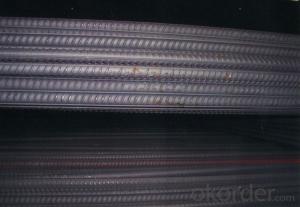

Hot -rolled bar 400MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRB400 is a kind of name of the new standard of reinforced, as one of the hot rolled ribbed steel bar. The name of the new standard for HRB400 reinforced, tertiary rebar for old said, as one of the hot rolled ribbed steel bar. In the construction industry, tertiary rebar is the last term.

Of the brand by HRB and number of hot rolled ribbed steel bar yield point of the minimum value. H, R, B Hot rolled (Hot rolled) respectively, ribbed (ribbed), steel bar (Bars) the first three words of English letters.

Classification of HRB400 -

Divided into HRB335 hot rolled ribbed bar (Numbers of 20 mnsi), HRB400 (the old number is 20 mnsiv, 20 mnsinb, 20 mnti), HRB500 three grades.

Fine grain hot-rolled reinforced its brands after the abbreviation of hot rolled ribbed steel bar and "Fine" (Fine), the first letter in English. Such as: HRBF335, HRBF400, HRBF500.

Have higher requirements of aseismatic structures for brand is: after the existing brand and E (for example: HRB400E, HRBF400E).

HRB400 - main purposes

Widely used in houses, Bridges, roads and other civil engineering construction.

HRB400 - leading producer

Rebar manufacturers in our country mainly in north and northeast, north China area such as shougang, tangshan, xuanhua, ChengGang, shanxi ZhongYang steel mills, baoding pury steel, northeast Westwood, north Taiwan, stroke, such as steel and so on, the two regions more than about 50% of the total output of rebar.

Rebar and light surface is the difference between a round bar with longitudinal and transverse ribs, usually with 2 longitudinal and cross rib of uniform distribution along the length direction. Belong to small section steel rebar, mainly used for reinforced concrete frame construction. In use requires a certain mechanical strength, bending deformation properties and welding performance. Production of raw materials of rebar steel billet calm smelting process in the carbon structural steel and low alloy structural steel, finished steel for hot rolling forming, is fire or hot rolling state delivery.

HRB400 - reverse bending performance

According to buyer's requirements, the rebar can reverse bending performance test.

Reverse bending test of curved heart diameter than the corresponding increase a rebar diameter bend test. Positively curved 45 degree first, and then reverse bending 23 degrees, reverse bending after 23 degrees. After reverse bend test, rebar bending parts surface shall not crack.

HRB400 - surface quality

Rebar surface permits can not have crack, scarring, and folding.

Rebar surface with convex block is allowed, but must not exceed the height of the horizontal rib, other defect depth and height of the rebar surface shall not be greater than their positions to allow the size deviation.

HRB400 - size, shape, weight, and allowable deviation

1. Nominal diameter range and recommend the diameter

Rebar nominal diameter in the range of 6 ~ 25 mm, standards recommended by the rebar nominal diameter is 6, 8, 10, 12, 16, 20, 25, 32, 40, 50 mm.

2. The ribbed steel plate surface shape and size of allowable deviation

Ribbed rebar cross rib shall meet the following basic requirements:

Axis transverse ribs with steel plate of beta should not be less than 45 degree Angle, when the Angle is not greater than 70 degrees, rebar relative to the direction of the horizontal rib on both sides should instead;

L cross rib and spacing shall not be greater than the rebar nominal diameter of 0.7 times;

Horizontal rib on the side and Angle on the surface of the rebar shall not be less than 45 degrees;

Rebar clearance between relative to the end of cross rib on both sides (including the longitudinal rib width) should not be greater than the sum rebar 20% of nominal circumference;

When the rebar nominal diameter is not more than 12 mm, relative costal area should not be less than 0.055; nominal diameter is 14 mm and 16 mm, relative costal area should not be less than 0.060; Nominal diameter greater than 16 mm, relative costal area should not be less than 0.065.

3. Length and allowable deviation

A, length: rebar usually according to the specified length delivery, specific delivery length should be indicated in the contract; rebar to volume delivery, each dish should be a rebar, allowing each group of 5% plate number (less than two sets can have two sets) consists of two rebar. Its diameter disc weight and plate shall be formulated by the supply and demand both sides talks things over.

B, the length of the allowable deviation: rebar according to scale the length of the delivery of the allowable deviation shall not be greater than + 50 mm.

C, bending and end: straight rebar bending change should not affect the normal use, the total curvature is not more than 40% of the total length of screw thread; Rebar ends should be cut integrity, local deformation shall not influence the use. [1]

HRB400 - need to detect project

Inspection items include: certificate number, rolling furnace number, grade, chemical composition (C, Si, Mn, P, V), tensile strength, yield point, elongation, relaxation rate, sectional area, product name, specification, quantity, delivery date, executive standard, receiving unit, etc. Only after inspection qualified can be for rebar, the acceptance of work.

- Q: What is the role of steel rebars in the construction of sports arenas and stadiums?

- Steel rebars play a crucial role in the construction of sports arenas and stadiums as they provide structural support and reinforcement to the concrete elements. They help enhance the strength, durability, and stability of the overall structure, ensuring it can withstand heavy loads, seismic forces, and other external pressures. Steel rebars also aid in preventing cracking and deformation of the concrete, thereby ensuring the safety of the spectators and the longevity of the facility.

- Q: Can steel rebars be used in structures with high chloride ion concentration?

- Steel rebars should generally not be used in structures with high chloride ion concentration, as the presence of chloride ions can lead to corrosion of the steel. Chloride ions can penetrate the concrete and come into contact with the steel reinforcement, causing it to corrode and weaken over time. This corrosion can eventually lead to structural failure and compromise the safety and integrity of the structure. To mitigate the risk of corrosion in high chloride ion environments, alternative materials such as stainless steel rebars or fiber-reinforced polymers (FRP) can be used. Stainless steel rebars are more resistant to corrosion compared to regular steel rebars due to their higher chromium content. FRP rebars, on the other hand, are non-metallic and do not corrode, making them a suitable option for structures exposed to high chloride ion concentrations. It is important to consider the specific environment and exposure conditions when selecting the appropriate material for reinforcement in structures. Consulting with a structural engineer and following relevant building codes and standards can help ensure the use of suitable materials and prevent potential corrosion issues in high chloride ion environments.

- Q: What is the process of removing rust from steel rebars?

- The process of removing rust from steel rebars involves several steps. 1. Inspection and assessment: Start by inspecting the extent of rust damage on the steel rebars. Determine whether the rust is superficial or has deeply penetrated the rebar. Assess the overall structural integrity of the rebars. 2. Safety precautions: Before starting the rust removal process, ensure that you are wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a respirator. This is important to protect yourself from any harmful chemicals or debris generated during the process. 3. Cleaning the surface: Begin by cleaning the surface of the rusted rebars using a wire brush or a grinder with a brush attachment. This helps remove loose rust, dirt, and other debris from the surface. Ensure that the surface is thoroughly cleaned before proceeding further. 4. Chemical treatment: Apply a rust converter or rust remover solution to the rusted areas of the rebar. These solutions typically contain chemicals that react with the rust, converting it into a stable compound or dissolving it entirely. Follow the instructions provided by the manufacturer for the specific product being used. 5. Mechanical removal: If the rust has not completely dissolved or converted after chemical treatment, it might be necessary to use mechanical methods to remove the remaining rust. This can be done by sanding the surface with sandpaper or using a wire brush to scrub off the remaining rust. 6. Rinse and dry: Once the rust has been removed from the steel rebars, rinse the surface thoroughly with clean water to remove any residual chemicals or debris. Allow the rebars to dry completely before any further treatment or application of protective coatings. 7. Prevention and protection: To prevent future rusting, it is essential to apply a protective coating or paint to the steel rebars. This acts as a barrier against moisture and air, which are the primary causes of rust formation. Choose a high-quality rust-resistant primer and paint specifically designed for steel reinforcement bars. It is crucial to note that removing rust from steel rebars is a task that requires expertise and adherence to safety precautions. In some cases, severe rust damage may require professional assistance or even replacement of the affected rebars.

- Q: What are the factors to consider while selecting steel rebars for a project?

- Some factors to consider while selecting steel rebars for a project include the grade and quality of the steel, the required strength and durability for the specific application, the size and shape of the rebars, the availability and cost of the materials, and any specific requirements or regulations set by the project specifications or local building codes.

- Q: Can steel rebars be used in structures with limited construction materials?

- Yes, steel rebars can be used in structures with limited construction materials. Steel rebars are commonly used as reinforcement in concrete structures to provide strength and stability. They can be easily transported and installed, making them suitable for construction projects in areas with limited access to construction materials. Additionally, steel rebars have high tensile strength, which enhances the durability and load-bearing capacity of structures, making them a reliable choice in resource-constrained environments.

- Q: Are steel rebars magnetic?

- Yes, steel rebars are magnetic as they are typically made from carbon steel, which is a ferromagnetic material.

- Q: Can steel rebars be used in structures with heavy snow loads?

- Yes, steel rebars can be used in structures with heavy snow loads. Steel rebars are commonly used in construction to reinforce concrete structures and provide additional strength. When designing structures in areas with heavy snow loads, engineers take into consideration the weight of the snow and ensure that the structure is designed to handle the additional load. Steel rebars are capable of withstanding heavy loads and can be used to reinforce the concrete in a structure, making it more resistant to the forces imposed by the snow. Additionally, steel rebars can also help distribute the load more evenly throughout the structure, reducing the risk of failure or collapse. However, it is important to consult with a structural engineer or a professional who is knowledgeable about local building codes and regulations to ensure that the structure is properly designed and built to withstand the specific snow load requirements in the area.

- Q: How do steel rebars improve the strength of concrete?

- Steel rebars improve the strength of concrete by providing reinforcement and enhancing its structural integrity. The rebars act as a skeleton, distributing and transferring the load across the concrete structure. This prevents cracks and increases the overall tensile strength of the concrete, making it more resistant to bending, shearing, and other external forces.

- Q: How do steel rebars affect the overall structural integrity of a building?

- Steel rebars play a crucial role in enhancing the overall structural integrity of a building. By reinforcing and strengthening concrete structures, rebars effectively distribute loads and resist tension, preventing cracks and structural failures. This reinforcement enables buildings to withstand various forces, such as earthquakes and high winds, ensuring their stability and durability over time.

- Q: How many kinds of steel are needed to build the building?

- The construction steel used to construct buildings can usually be divided into steel structures, steel and reinforced concrete structures. Steel structural steel mainly consists of ordinary carbon structural steel and low alloy structural steel. It's made of steel, steel pipe and steel bar. There are angle steel, I-beam and channel steel in section steel. Reinforcing bars for reinforced concrete structures.

Send your message to us

Hot -rolled bar 400MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords