Aluminum Hot Rolled Circle/Disc A1050 1060 O H12 for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot rolled Aluminum Circle/Disc A1050 1060 O H12 for Cookware

(1)Alloy:1000series:1050 1060 1070 1100 1200 and other 1000series

3000series:3003 3004 and other 3000series

5000series:5005 5052 5754 5083 5086 and other 5000series

(2)Temper: O H H12 H14 H18 H24 H32 H34

(3)Thickness(mm):0.3-6.0mm

(4)Width(mm):50mm-1500mm

(5)Main application: Road signs,lighting,closures,Pan,cooking utensils, food processing equipment, storage tanks, truck and trailer components, aircraft components,

(6) Quality of material:

Totally free from defects like White Rust, Oil Patches, Roll Marks, Edge Damage, Camber, Dents, Holes, Break Lines, Scratches and free from circle set.

(7)Surface Finish:

Bright & smooth surface, without flow lines, slightly oiled to avoid White rusting

(8)Payment term:T/T,L/C

(9)Packing: Standard Export Packaging or According to Customers' Requirements

(10)Chemistry composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | --- | --- | 0.05 | 0.03 | 99.6 |

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | --- | --- | 0.05 | 0.03 | 99.5 |

1100 | 0.95 | 0.05-0.2 | 0.05 | --- | --- | --- | 0.1 | --- | 99.0 | |

1200 | 1.0 | 0.05 | 0.05 | --- | --- | --- | 0.1 | 0.05 | 99.0 | |

2.Main Features of the Hot rolled Aluminum Circle/Disc A1050 1060 O H12 for Cookware

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

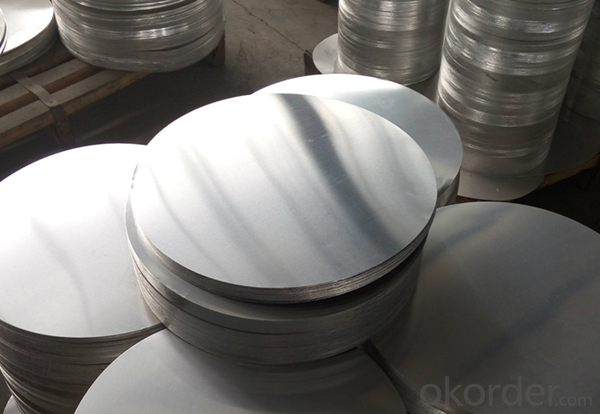

3.Hot rolled Aluminum Circle/Disc A1050 1060 O H12 for Cookware Images

4.Hot rolled Aluminum Circle/Disc A1050 1060 O H12 for Cookware Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Hot rolled Aluminum Circle/Disc A1050 1060 O H12 for Cookware

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

5.Quality contral:

1. Professional Quality Control Team

v Inspecting ingot before melting

v Inspecting aluminium coil stock before cold rolling

v Inspecting finished goods before package

v Inspecting package, loading before shipment

2. Guaranteed by ISO 9001:2008 (SGS)

3. Guaranteed by FDA, EN 602, TPCH etc

- Q: Is it possible to recycle aluminum cans and turn them into new cans?

- <p>Yes, aluminum cans can be recycled into new ones. The recycling process involves melting the used cans, which is much less energy-intensive than extracting and refining new aluminum from bauxite ore. Once melted, the aluminum can be reshaped into new cans or other products. This process is not only environmentally friendly but also economically efficient, as it saves energy and reduces waste.</p>

- Q: What is the measure of aluminum's strength, specifically its yield strength and tensile strength?

- <p>Aluminum's strength is typically measured in terms of its yield strength and tensile strength. The yield strength of aluminum varies depending on the alloy and heat treatment, but it generally ranges from 10 to 45 MPa. Tensile strength, which is the maximum stress that aluminum can withstand before breaking, is typically between 90 to 600 MPa for different aluminum alloys. These values make aluminum a lightweight yet strong material suitable for various applications, including construction, automotive, and aerospace industries.</p>

- Q: Explain how the production process of recycled aluminum differs from that of new aluminum, focusing on energy consumption and environmental impact.

- <p>The production process for recycled aluminum is significantly less energy-intensive compared to the production of new aluminum. Producing new aluminum from bauxite ore requires high temperatures and substantial energy, often from fossil fuels, to smelt the ore and extract the metal. This process emits greenhouse gases and consumes large amounts of electricity. In contrast, recycling aluminum involves melting down existing aluminum products, which requires only about 5% of the energy needed to produce new aluminum. This process is more environmentally friendly, as it reduces energy consumption, lowers greenhouse gas emissions, and conserves natural resources by decreasing the need for raw materials.</p>

- Q: Explain the differences between aluminum and iron, including their properties and uses.

- <p>Aluminum and iron are distinct metals with different properties and uses. Aluminum is lightweight, corrosion-resistant, and has a lower melting point, making it ideal for applications like beverage cans, aircraft construction, and electrical wiring. It is a good conductor of heat and electricity but is less strong than iron. Iron, on the other hand, is heavier, stronger, and has a higher melting point. It is a key component in steel, which is used extensively in construction, automotive, and machinery due to its strength and durability. Iron is also magnetic, unlike aluminum, and is crucial in electromagnetism applications.</p>

- Q: What is the primary application of aluminum in various industries and everyday life?

- <p>Aluminum is most commonly used in the manufacturing of cans and packaging materials due to its lightweight, corrosion resistance, and recyclability. It is also extensively used in construction for window frames, roofing, and facades. In transportation, aluminum is a key material in the production of vehicles, particularly in the aerospace industry for aircraft and automotive industry for car bodies, due to its strength-to-weight ratio. Additionally, it is used in electrical components and electronics due to its good conductivity and malleability.</p>

- Q: What are some potential alternative uses for recycled aluminum that haven't been widely considered?

- <p>Recycled aluminum has a wide range of potential uses beyond the common ones like beverage cans and automotive parts. It can be used in the construction of buildings and infrastructure due to its strength and lightness. Additionally, it can be utilized in the aerospace industry for crafting aircraft components, given its resistance to corrosion and fatigue. In the electronics sector, recycled aluminum can be employed in the production of various components, such as circuit boards and casings. Moreover, it can be used in the creation of consumer goods like furniture, as well as in the packaging industry for food and pharmaceutical products. The versatility of recycled aluminum makes it a sustainable choice for many industries, reducing waste and environmental impact.</p>

- Q: Is it safe to use aluminum for making containers for food and beverages?

- <p>Yes, aluminum can be used to make containers for food and drink. Aluminum is a common material for food packaging due to its lightweight, durability, and resistance to corrosion. It forms a protective oxide layer that prevents the metal from interacting with the food, ensuring safety. However, it's important to note that aluminum containers should not be used for storing acidic foods or beverages for extended periods, as this can lead to leaching of aluminum into the food. Additionally, some studies suggest a potential link between aluminum and neurological disorders, though this is still a subject of debate.</p>

- Q: This question asks for an overview of the environmental concerns associated with the manufacturing process of aluminum.

- <p>The production of aluminum is associated with several environmental issues. One major concern is the high energy consumption required for the smelting process, which contributes to greenhouse gas emissions. The process also generates significant amounts of waste, including red mud, a hazardous byproduct that can contaminate soil and water if not properly managed. Additionally, deforestation and habitat destruction occur due to the mining of bauxite, the primary ore of aluminum. Air pollution is another issue, as the production process releases particulates and other pollutants into the atmosphere. Lastly, the depletion of non-renewable resources, such as fossil fuels used in the smelting process, is a long-term environmental concern related to aluminum production.</p>

- Q: This question asks about the amount of energy needed to produce aluminum, including the process and factors that influence energy consumption.

- <p>Producing aluminum requires a significant amount of energy, primarily due to the electrolytic process used to extract it from its ore, bauxite. The Hall-H茅roult process, the most common method, consumes about 15,000 to 16,000 kilowatt-hours of electricity per ton of aluminum produced. This high energy demand is largely due to the strong chemical bonds in aluminum oxide, which must be broken to release the aluminum. Energy consumption can vary based on the efficiency of the smelting process, the quality of the bauxite, and the energy source used, with renewable energy potentially reducing the carbon footprint but not necessarily the total energy input.</p>

- Q: Dangemen mills and other Aluminum Alloy and enterprises what is the difference?

- I looked at the statistics, found that Aluminum Alloy door enterprises Dangemen factory is the only one focused on the balcony.

Send your message to us

Aluminum Hot Rolled Circle/Disc A1050 1060 O H12 for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords