Hot Rolled 1065 High Carbon Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled 1065 High Carbon Steel Bars

Technical Paramenters

Description | 1065 steel rould bar | |

Material Range | ASTM /AISI | 1005,1006,1008,1010,1015,1020,1025,1030,1035, 1040,1045,1050,1055,1060,1065,1070,1080,1084 |

DIN | Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

Standard | GB/T799,ASTM A29,A36,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

Section shape | Round Other shape such as square,hexagonal,flat,angle | |

Surface | Black, galvanized,grinded, | |

Specifications | Round bar | Diameter: 12mm~650mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square/ bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width:10mm~500mm | ||

Hexagonal | Size: 4mm~800mm | |

Length | Standard 6m,9m,12m or as required. | |

Trade terms | Payment terms | T/T,L/C,Western Union |

Price terms | FOB,CIF,CFR,EXW | |

Applications | Steel round bar is widely used for all general fabrication and repairs in industrial maintenance, agricultural implements, transportation equipment, ornamental work frame work, braces, supports, shafts,axels,etc. Hot rolled Steel round bars have a slightly grain textured finish. | |

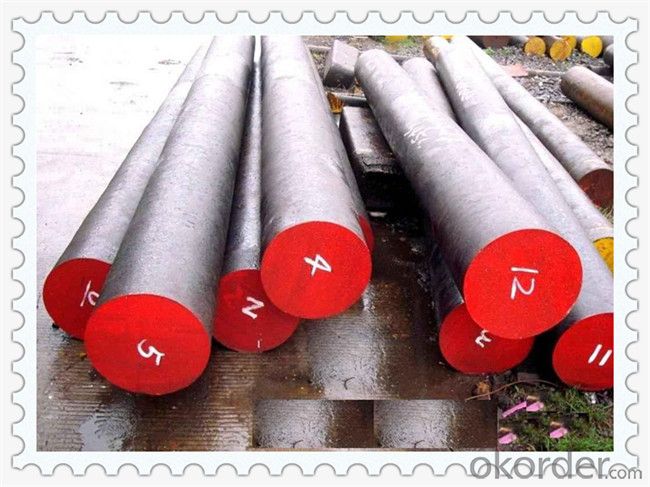

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: On the market, 8mm Round Bar is not 9 meters a root? How much does it weigh about 300 meters? How much does it cost?

- Method of calculating reinforcement weight, unit length, weightD*d*0.00617= (6 in 7)For example, 8mm steel 8*8*0.00617=0.39488 take 0.395Round steel and rib are calculated the same wayRound bar 8 is rolled up, usually between 2~4 tonsYou'll have to straighten it up, straighten it up, and straighten it up

- Q: Can steel round bars be used for shafts or axles?

- Indeed, shafts or axles can make use of steel round bars. In a multitude of industries, including automotive, machinery, and construction, steel round bars are frequently employed due to their robustness, longevity, and adaptability. Their selection for shafts or axles often stems from their capacity to endure substantial loads, furnish dependable support, and endure wear and tear. By virtue of being machinable and amenable to heat treatment, steel round bars can be customized to meet specific prerequisites, rendering them well-suited for deployment as shafts or axles in a wide range of applications where strength and dependability are paramount, such as vehicles, industrial apparatus, and rotating machinery.

- Q: Can steel round bars be used in the manufacturing of springs?

- Indeed, the utilization of steel round bars in the production of springs is possible. Steel, being a prevalent material in spring manufacturing, is favored for its remarkable attributes including remarkable strength, endurance, and flexibility. By employing diverse manufacturing techniques like hot rolling, cold drawing, or machining, steel round bars can be skillfully transformed and molded into the desired spring shape. The selection of the precise type of steel round bar relies on the application and specific characteristics sought after for the spring, such as the desired level of rigidity or resilience. All in all, steel round bars are extensively employed and deemed as a dependable option for spring production.

- Q: Can steel round bars be used in the manufacturing of garden tools?

- Absolutely, garden tools can certainly incorporate steel round bars in their manufacturing process. Steel, known for its versatility and durability, is widely employed in the production of diverse tools, particularly those used in gardens. Shovels, rakes, hoes, and pruning shears are just a few examples of garden implements that can be crafted using steel round bars, thanks to their malleability. The exceptional strength and resilience of steel render it perfectly suited for enduring the strenuous demands of outdoor activities like digging, cutting, and scraping. Moreover, steel can be effortlessly honed and maintained, ensuring that the garden tools retain their efficacy and longevity.

- Q: What are the advantages of using wear-resistant steel round bars?

- There are several advantages of using wear-resistant steel round bars: 1. Enhanced durability: Wear-resistant steel round bars are specifically designed to withstand high levels of abrasion and wear. They have a high hardness level and are resistant to surface damage caused by friction, impact, or scraping. This results in a longer lifespan of the round bars, reducing the need for frequent replacements. 2. Increased strength: Wear-resistant steel round bars possess exceptional strength properties, allowing them to withstand heavy loads and extreme conditions. This makes them suitable for a wide range of applications, such as in industries like mining, construction, manufacturing, and transportation, where strength and resilience are crucial. 3. Improved safety: The use of wear-resistant steel round bars ensures a safer working environment. Their high resistance to wear minimizes the risk of accidents and injuries caused by equipment failures or structural damage. This is particularly important in industries where heavy machinery, tools, or structures are involved. 4. Cost-effectiveness: Although wear-resistant steel round bars may have a higher initial cost compared to regular steel bars, their extended lifespan and reduced maintenance requirements make them a cost-effective choice in the long run. The reduced need for replacements and repairs leads to lower downtime, increased productivity, and ultimately, decreased operational costs. 5. Versatility: Wear-resistant steel round bars can be used in a variety of applications due to their versatility. They can be easily machined, welded, or formed into different shapes and sizes to meet specific requirements. This flexibility allows for their use in various industries and applications, making them an ideal choice for many projects. In summary, the advantages of using wear-resistant steel round bars include enhanced durability, increased strength, improved safety, cost-effectiveness, and versatility. These properties make them a reliable and efficient option for applications where wear and tear are significant concerns.

- Q: How do you measure the diameter tolerance of a steel round bar?

- To determine the diameter tolerance of a steel round bar, one can adhere to the following procedure: 1. Acquire a caliper or micrometer, which are commonly employed tools for accurately gauging object diameters. 2. Set up the measuring tool appropriately: Adjust the jaws of the caliper to the suitable size range or ensure correct zeroing of the micrometer. 3. Situate the round bar: Place the steel round bar on a stable and flat surface, taking care to prevent any rolling or movement. 4. Perform the measurement: Utilize the measuring tool to record the diameter of the round bar. For precise outcomes, ensure that the tool is perpendicular to the bar and exert gentle pressure to obtain an accurate reading. 5. Repeat the measurement: To ensure accuracy, take multiple measurements at various points along the length of the round bar. This will account for any variations or deviations in the bar's diameter. 6. Calculate the average diameter: Sum up all the measurements and divide by the number of measurements taken. This will yield the average diameter of the round bar. 7. Compare with the tolerance range: Refer to the provided specifications or standards for the steel round bar to ascertain the allowable tolerance range. This range will indicate the acceptable variation in diameter for the bar. 8. Analyze the findings: Compare the average diameter derived from the measurements with the specified tolerance range. If the average diameter falls within the tolerance range, the round bar complies with the required specifications. However, if it deviates beyond the range, further inspection or adjustment may be necessary to meet the required tolerance. By adhering to these steps, one can effectively gauge the diameter tolerance of a steel round bar and ensure its conformity to the necessary specifications for the intended application.

- Q: Can steel round bars be annealed?

- Yes, steel round bars can be annealed. Annealing is a heat treatment process that involves heating the steel to a specific temperature and then gradually cooling it down. This process helps to relieve internal stresses, improve ductility, and enhance the material's machinability. Annealing can be applied to a wide range of steel products, including round bars, to make them softer, more workable, and reduce the risk of cracking or failure during subsequent manufacturing processes.

- Q: Can steel round bars be used for making electrical components?

- Whether steel round bars can be used for making certain electrical components depends on the specific requirements and applications. Steel is a versatile material that possesses good electrical conductivity and high durability, making it well-suited for a variety of electrical applications. However, when it comes to components that necessitate specific electrical properties or insulation, copper or aluminum may be more commonly utilized. Furthermore, in order to prevent corrosion or enhance electrical conductivity, it may be necessary to subject steel round bars to surface treatments or coatings. Ultimately, the appropriateness of utilizing steel round bars for manufacturing electrical components should be evaluated in accordance with the specific requirements and regulations of the intended application.

- Q: Are steel round bars resistant to abrasion?

- Steel round bars are typically resistant to abrasion. Steel is renowned for its strength and durability, allowing it to withstand the effects of friction and contact with other surfaces. However, the degree of abrasion resistance can differ based on the particular steel type and composition. Some steel grades, like hardened or alloy steels, are specifically engineered to possess enhanced resilience against abrasion. These steels undergo procedures like heat treatment or alloying to enhance their hardness and augment their ability to endure abrasion. All in all, steel round bars are a dependable option for situations where abrasion resistance is crucial.

- Q: What is the difference between a seamless and a welded steel round bar?

- The main difference between a seamless and a welded steel round bar lies in their manufacturing processes. A seamless steel round bar is produced by piercing a solid cylindrical billet, while a welded steel round bar is created by welding together multiple pieces of steel. This results in a seamless bar having a smoother surface and uniform composition, making it stronger and more resistant to corrosion. On the other hand, a welded round bar may have visible seams due to the welding process, which can affect its strength and durability.

Send your message to us

Hot Rolled 1065 High Carbon Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords