Hot Rolled Carbon Steel Round Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Carbon Steel Round Bars S10C

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| S10C | 0.08-0.13 | 0.15-0.35 | 0.30-0.60 | ≤0.030 | ≤0.030 | ≤0.20 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Reduction of Area ψ | Elogation δ5 | Hardness |

| ≥335(34) Mpa | ≥205(21) Mpa | ≥55% | ≥31% | ≤137HB |

3, Diameter: 16mm - 300mm

Length: Max 12m

Application

Can be used to manufacture weld assembly, cold stamping parts, forge pieces and carburized parts which do not require high strength such as bolts, washers, plate, shell, etc.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

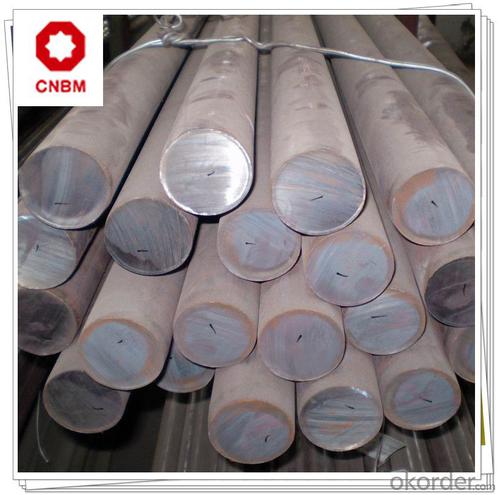

Product Show

Work Shop

About Us

- Q: What is the difference between a smooth and a ribbed steel round bar?

- The surface texture and intended use differentiate a smooth steel round bar from a ribbed steel round bar. A smooth steel round bar possesses a surface that is uniform and even, devoid of any ridges or indentations. Its application is mainly in projects that desire a sleek and polished appearance, like decorative or architectural endeavors. Additionally, smooth bars find common usage in machining processes where precision and accuracy necessitate a smooth surface. Conversely, a ribbed steel round bar comprises raised ridges or ribs along its length. These ridges contribute to better grip and traction, making ribbed bars optimal for tasks demanding substantial strength and stability. In the construction industry, ribbed bars are frequently employed to reinforce concrete structures such as buildings, bridges, and highways. The ridges on the bar heighten the bond between the concrete and the steel, thereby enhancing the overall structural integrity. To sum up, the key contrast between a smooth and ribbed steel round bar lies in their surface texture and intended use. Smooth bars are valued for their polished appearance and precision machining, whereas ribbed bars are designed to deliver enhanced grip and reinforcement in concrete structures.

- Q: Lightning protection earthing zinc plating flat iron and round steel welding method, need to flat iron wrapped in round steel outside welding?

- The flat steel is not required to be wrapped outside the round bar, and the round steel can be directly welded on the flat steel, and the welding joint area can not be smaller than round steel or flat steel, and the section is a cross section

- Q: What are the advantages of using steel round bars over other materials?

- There are several advantages to using steel round bars over other materials: 1. Strength and durability: Steel round bars are known for their high strength and durability, making them suitable for various applications. They can withstand heavy loads and resist deformation, making them ideal for structural purposes. 2. Versatility: Steel round bars come in a wide range of sizes, grades, and finishes, making them highly versatile. They can be easily customized to meet specific requirements, such as different lengths, diameters, and surface finishes. 3. Cost-effective: Steel round bars offer a cost-effective solution compared to other materials. Their abundance and efficient manufacturing processes make them readily available and affordable. Additionally, their high strength-to-weight ratio allows for the use of smaller quantities of steel while achieving the same level of strength. 4. Corrosion resistance: Steel round bars can be produced with different finishes, including galvanized or stainless steel, which enhances their resistance to corrosion. This makes them suitable for outdoor applications or in environments where they may come into contact with moisture or chemicals. 5. Machinability: Steel round bars are known for their excellent machinability, meaning they can be easily cut, drilled, or shaped to meet specific design requirements. This characteristic allows for efficient processing and reduces production costs. 6. Fire resistance: Steel is inherently fire-resistant and does not contribute to the spread of flames. This makes steel round bars a preferred choice in applications where fire safety is a concern, such as in construction or industrial settings. 7. Recyclability: Steel is highly recyclable, which makes steel round bars an environmentally friendly option. They can be easily melted down and reused to create new steel products without losing their properties or strength. Overall, the advantages of using steel round bars over other materials include their strength, durability, versatility, cost-effectiveness, corrosion resistance, machinability, fire resistance, and recyclability. These factors make steel round bars a preferred choice in various industries, including construction, manufacturing, automotive, and infrastructure projects.

- Q: How do you calculate the deflection of a steel round bar?

- To calculate the deflection of a steel round bar, you need to consider various factors such as the bar's length, diameter, and the applied load. The deflection of a bar refers to the amount it bends or flexes under a specific load. The deflection can be determined using the formula for beam deflection, which is derived from Euler-Bernoulli beam theory. The formula is as follows: δ = (F * L^3) / (48 * E * I) Where: - δ represents deflection - F is the applied load - L is the length of the bar - E is the modulus of elasticity of the steel material - I is the moment of inertia of the round bar To calculate the moment of inertia (I) for a round bar, you can use the formula: I = (π * D^4) / 64 Where: - I is the moment of inertia - D is the diameter of the round bar By substituting the values into the formula, you can calculate the deflection of the steel round bar under the given load. It is important to note that these calculations assume the bar is perfectly elastic and obeys the principles of linear elasticity.

- Q: Are steel round bars prone to fatigue failure?

- Fatigue failure is a common occurrence in steel round bars, which can be attributed to repeated cyclic loading or stress. This leads to a gradual weakening of the material, eventually causing it to fail, even if the applied stress is below its ultimate strength. Due to their inherent characteristics, steel round bars, like other structural materials, are susceptible to fatigue failure. Various factors can contribute to fatigue failure in steel round bars, including improper design, inadequate material selection, manufacturing defects, and excessive cyclic loading. Additionally, surface defects, notches, stress concentrations, and corrosive environments can further accelerate the fatigue process. Engineers and designers take several measures to mitigate the risk of fatigue failure. These include implementing appropriate design practices, selecting high-quality materials, conducting thorough inspections, applying stress-relieving treatments, and considering the impact of cyclic loading during the structural design phase. It is important to understand that the susceptibility of steel round bars to fatigue failure depends on multiple factors, such as the specific steel grade, loading conditions, environmental factors, and overall structural design. Therefore, it is crucial to carefully assess these factors and employ appropriate mitigation measures to ensure the safe and reliable performance of steel round bars in various applications.

- Q: How are steel round bars used in the automotive industry?

- Steel round bars are commonly used in the automotive industry for various applications such as manufacturing of axles, drive shafts, suspension components, and steering systems. These bars provide high strength and durability, allowing them to withstand the heavy loads and harsh operating conditions of vehicles. Additionally, steel round bars can be machined and formed into desired shapes, making them versatile and suitable for different automotive parts.

- Q: Are steel round bars suitable for use in the aerospace industry?

- Yes, steel round bars are suitable for use in the aerospace industry. Steel round bars offer excellent strength and durability, making them an ideal choice for various applications in aerospace engineering. They have a high tensile strength and can withstand extreme temperatures and pressures often encountered in aerospace operations. Steel round bars also have good corrosion resistance, which is crucial for maintaining structural integrity in aircraft exposed to different environmental conditions. Moreover, their machinability and weldability make them versatile for manufacturing components and structures in the aerospace industry. Overall, steel round bars are a reliable and cost-effective material choice for aerospace applications.

- Q: Can steel round bars be welded to other materials?

- Other materials can indeed be joined with steel round bars through welding. Welding is a widely used technique for merging various materials, including steel round bars, aluminum, stainless steel, and even non-metallic substances like plastics. However, it is vital to emphasize that successful welding depends on the compatibility of the materials being joined. To ensure a robust and long-lasting bond between the steel round bar and the other material, the welding process necessitates the use of appropriate techniques, filler metals, and sometimes pre-heating or post-weld heat treatment. Moreover, it is important to consider the specific application and the desired properties of the joint in order to determine the most suitable welding method and materials.

- Q: Are steel round bars suitable for bicycle frame applications?

- Yes, steel round bars are suitable for bicycle frame applications. Steel is a commonly used material for bicycle frames due to its strength, durability, and ability to absorb vibrations. Round bars provide a strong and rigid structure, allowing for a stable and reliable frame that can withstand the stresses and strains of regular use.

- Q: Can steel round bars be used for making storage tanks?

- Yes, steel round bars can be used for making storage tanks. Steel is a versatile and widely used material in various industries, including the manufacturing of storage tanks. Steel round bars are known for their strength, durability, and resistance to corrosion, making them suitable for storing a wide range of substances, including liquids and gases. The round shape of the bars allows for easy fabrication and assembly, ensuring the structural integrity of the storage tank. Additionally, steel round bars can be easily welded or bolted together, allowing for customization and flexibility in tank design. Overall, steel round bars are a popular choice for making storage tanks due to their reliability, longevity, and ability to withstand high pressure and extreme environmental conditions.

Send your message to us

Hot Rolled Carbon Steel Round Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords