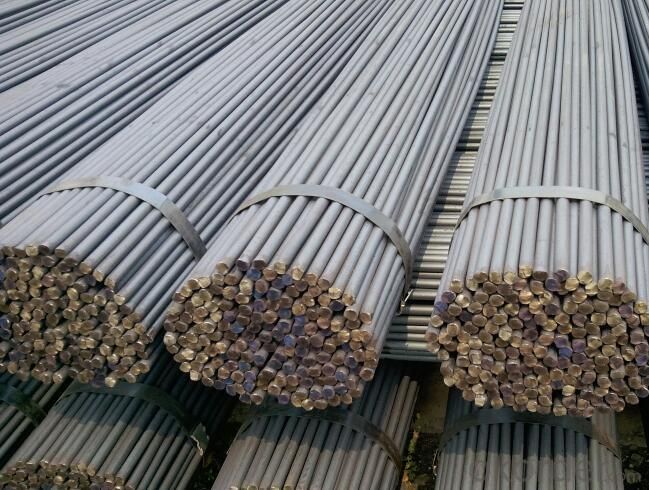

Round steel bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Size:DiameterΦ8-Φ300MM Length:500-8000MM

Surface condition:Lathe polished,descaling,black,acid-producing white,drawn-bright.

Quality assurance:All forged round bar has obtained the certificate of National Level Standard Ultrasonic Flaw Detection.

Inquiry content

1. Product standards

2. Size(Diameter and Length)

3. Surface condition

4. Heat treatment condition

5. Quantity Required

Product introduction:

NS143,20#Alloy,N08020,Alloy 20cb3,Carpenter20Alloy,ALLOY20 is a kind of corrosion resistant alloy which has many superior performance, It has a good ability to resist oxidation ,medium deoxidation corrosion, stress corrosion cracking and local corrosion, its performance satisfies many chemical process, just like inorganic acid solution of strong erosiveness, chlorine and all kinds of medium containing chloride, dry chlorine , formic acid, acetic anhydride, seawater and salt water, etc.

Specialty: resistance to oxidation - reducing composite medium corrosion.

Application: Sulfuric acid environment and sulfuric acid solution which containis LuZu ion and metal ion, such as hydrometallurgy and sulphuric acid industry device.

Detailed Product Description of Skd11 Round Bar Size

We respond to requirements for a wide range of materials including steel for tools, stainless steel, and even aluminum

Please rely on us for any kind of specialist steel.

We mainly offer structural steel, but can offer any other types including tool steel,stainless steel and even aluminium.We can respond to

requests for a wide range of materials.

Please rely on us for quick delivery with short lead times.

We understand well that delivery delays lead to major losses in missed opportunities and lost profits.

We will always endeavor to realize the shortest possible delivery times and to deliver at the time you require.

Please rely on us for high precision processing.

We have a selection of processing machinery, including high precision cutting machines, and will deliver to you after processing into your

required shapes and lengths.

Quality Assurance of Steel Round Rod Bar

1. We will strictly inspect our production that we sold according to the customer’s request.

2. Our steel reaches international quality standards.

3. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

4. Should the packing found damaged, the buyer has the right to claim to the seller.

- Q: What are the different grades of tool steel round bars?

- Tool steel round bars are available in various grades, each offering unique properties and characteristics to suit specific applications. Some of the different grades of tool steel round bars include: 1. W1: This is a water-hardening tool steel with relatively low carbon content. It is known for its excellent toughness and good wear resistance. W1 tool steel round bars are commonly used for cutting tools and woodworking tools. 2. O1: O1 tool steel round bars are oil-hardening tool steel with high carbon content. They have good wear resistance, high toughness, and excellent dimensional stability. O1 tool steel is often used for punches, dies, and cutting tools. 3. A2: A2 tool steel round bars are air-hardening tool steel with medium carbon and chromium content. They offer good wear resistance, excellent toughness, and high dimensional stability. A2 tool steel is commonly used for blanking and forming dies, as well as shear blades. 4. D2: D2 tool steel round bars are high-carbon, high-chromium tool steel with excellent wear resistance and good toughness. They offer high resistance to abrasive wear and are often used for making cutting tools, punches, and forming dies. 5. M2: M2 tool steel round bars are high-speed steel with a significant amount of tungsten, molybdenum, and vanadium. They have exceptional wear resistance, high red hardness, and good toughness. M2 tool steel is typically used for high-speed cutting tools, drill bits, and machining tools. 6. S7: S7 tool steel round bars are air-hardening shock-resistant tool steel. They have high impact toughness, good wear resistance, and excellent heat resistance. S7 tool steel is commonly used for applications that require high shock resistance, such as chisels and hammers. These are just a few examples of the different grades of tool steel round bars available in the market. The choice of grade depends on factors such as the specific application, desired hardness, wear resistance, toughness, and heat resistance required. It is important to consult with a knowledgeable supplier or metallurgist to determine the most suitable grade for a particular application.

- Q: Can steel round bars be coated or plated?

- Yes, steel round bars can be coated or plated. Coating or plating is a common process used to enhance the performance and aesthetics of steel products. There are various coating and plating options available, such as zinc plating, chrome plating, nickel plating, and powder coating. These processes can provide additional protection against corrosion, improve wear resistance, and give the steel a desired appearance. The choice of coating or plating method depends on the specific application and requirements of the steel round bars.

- Q: What is the difference between a rough turned and a polished steel round bar?

- A rough turned steel round bar has undergone a preliminary machining process that removes surface imperfections and excess material, providing a slightly smoother finish. On the other hand, a polished steel round bar has undergone further polishing or grinding processes to achieve a much smoother and aesthetically appealing surface finish.

- Q: The difference between round steel and screw steel

- The difference between round bar and round bar is that the surface has longitudinal ribs and transverse ribs, usually with two longitudinal ribs and transverse ribs uniformly distributed along the length direction. The rebar is a kind of small section steel, mainly used for the skeleton of reinforced concrete construction members. In use, some mechanical strength, bending deformation property and welding performance are required. The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q: Can steel round bars be used for construction purposes?

- Indeed, construction purposes can make use of steel round bars. Several applications in construction commonly utilize steel round bars, including reinforcement in concrete structures, support for beams and columns, and as structural components in bridges, buildings, and infrastructure projects. The exceptional tensile strength and durability of steel render it a perfect option for construction purposes, capable of withstanding heavy loads, providing stability, and ensuring the longevity and safety of structures. Furthermore, steel round bars offer versatility, as they can be easily fabricated and customized to meet specific project requirements. Hence, due to their excellent mechanical properties, reliability, and cost-effectiveness, steel round bars find extensive use in the construction industry.

- Q: Can steel round bars be painted or coated?

- Yes, steel round bars can be painted or coated with various types of protective coatings to enhance their durability and prevent corrosion.

- Q: Can steel round bars be used for making fasteners or bolts?

- Certainly! The utilization of steel round bars is viable for the production of fasteners and bolts. Steel is widely employed as a material for these components due to its exceptional robustness, longevity, and resistance against corrosion. The round bars, crafted from steel, can be effortlessly manipulated and threaded, enabling the creation of an array of fasteners and bolts such as screws, nuts, and threaded rods. The selection of the precise steel grade hinges upon the specific application and desired strength properties. Nevertheless, it is imperative to bear in mind that the manufacturing process and stringent quality control are paramount in guaranteeing the dependability and performance of the end product.

- Q: How are steel round bars used in the manufacturing of hydraulic systems?

- Steel round bars are commonly used in the manufacturing of hydraulic systems as they provide strength, durability, and stability to various components such as pistons, cylinders, and shafts. They are machined and shaped to create precision parts that can withstand high pressure and repetitive movements. The use of steel round bars ensures the reliable and efficient functioning of hydraulic systems, making them an integral part of their construction.

- Q: What are the applications of steel round bars?

- Steel round bars have a wide range of applications across various industries. They are commonly used in construction for structural support, such as in the fabrication of beams, columns, and trusses. Steel round bars are also used in the manufacturing of machinery and equipment, including shafts, axles, gears, and bolts. Moreover, they find utility in the automotive industry for the production of components like suspension systems, chassis, and engine parts. Additionally, steel round bars are employed in the production of tools, such as drill bits, punches, and hammers. Overall, their strength, durability, and versatility make steel round bars an essential material in numerous applications.

- Q: Can steel round bars be used for making exercise equipment?

- Steel round bars are a viable option for manufacturing exercise equipment due to their durability and strength. These bars are renowned for their ability to withstand heavy loads and provide stability during workouts, making them suitable for constructing various types of fitness equipment. Weightlifting bars, dumbbells, barbells, and other exercise equipment that require reliable materials can be created using steel round bars. Moreover, these bars can be easily machined, welded, and shaped into different forms, allowing for customization and versatility in exercise equipment design. As a result, steel round bars are favored by gym equipment manufacturers and fitness enthusiasts alike.

Send your message to us

Round steel bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords