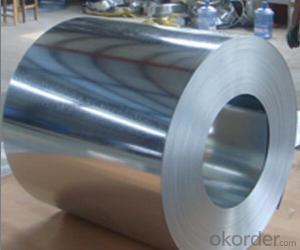

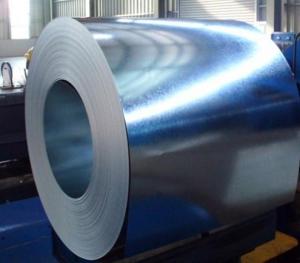

Hot Dipped Galvanized Steel Coil High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Dipped Galvanized Steel Coil High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Dipped Galvanized Steel Coil High Quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Dipped Galvanized Steel Coil High Quality are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

| Packaging Detail: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection. |

| Delivery Detail: | 3-10days after receving the deposite |

gavanized steel coil

1) cold rolled steel plate

2) SUCC ,DC01 ,SPCC.

3) Standard GB13237 Q/ ASB 334

gavanized steel coil

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Material: Q195, Q235, SPCC, Q195L, Q195LD, 08AL

We can supply various models, specifications, and varieties of steel coil and plates. Including cold rolled, hot rolled, galvanized and so on.

The products conform to the national standards completely, and are widely used.

Our cold rolled steel sheet/coil/strips may have custom-made each kind of material and the specification according to customer request.

Product Application:

Machine made industry, chemical industry, spin, shipping industry, kitchen appliance, mechanical, electrical equipment, stainless steel furniture and building construction, outdoor railling, etc

(Cold Rolled Sheet/Coil/strip)

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Material: Q195, Q235, SPCC, Q195L, Q195LD, 08AL

3) Thickness: 0.15mm-5.0mm

4) Width: 600mm-2000mm

5) Length: As requested

6) Width tolerance: different as per different width

7) Thickness tolerance: different as per different thickness

8) Weight: According to the different requirement

9) Packing: Mill standard export packing in bundles

10) Country of Origin : China

11) Delivery Time : 7-15 days after we receive your T/T or L/c

12) Shipment: By bulk vessel or By container

13) Surface: General, Bright, Dull and Mirror finish, oiled or unoiled

14) Packing: Standard exporting packing with edge protector, steel hoop and seals, or as per customer's requirement.

We have good cooperation with factory,so we are able to supply the goods which are needed by you.

We are large and professional exporter for steel products and enjoy good reputation because of our high quality and competitive price.Our stainless steel goods has beautiful surface, corrosion resistance,more durable than common plate;Clean,high temperature resistant;Welding performance is good. We are willing to establish business relations with customers on the basis of equality and mutual benefit.I look forward to serving you, welcome inquiry!

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes by being uncoiled, flattened, and then formed into a cylindrical shape through a process called pipe welding. The steel coils provide the necessary raw material for the production of pipes, ensuring strength, durability, and structural integrity.

- Q: 911 conspiacy theorists. Can fire melt steel?

- So does fuel also generate timed explosions that were heard by firemen? Why do we see melting steel that looks like thermite burning? Does the jet fuel also destroy the entire 80 stories of steel support structure as well? (This is required to account for the free-fall speed of the collapse of three buildings. That's right, three buildings collapsed at near free-fall speeds in NYC in the WTC complex.) The government's conspiracy theory is totally inconsistent with the facts. The only theory that has coherence at the moment is the demolition theory presented by Professor Steven Jones of BYU (Physics). I've seen no credible challenges to the 13 points he presented in an academic paper on this topic. I'd very much like to see a credible explanation for the free-fall collapse of all three buildings.

- Q: My boyfriend says he has balls of steel.

- Easy to test. Put a magnet near them. If they attract, then they're made of steel. I'd be willing to bet I'd know what will happen, though! I know you can get metal hip replacements but .........

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The common coil diameter and weight combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some commonly used combinations that are widely available in the market. In terms of coil diameter, the most common sizes range from 24 inches (610 mm) to 72 inches (1829 mm). These diameters are typically used for various applications in industries such as automotive, construction, and manufacturing. Regarding coil weight, the range can vary significantly depending on the type and thickness of the steel being coiled. For hot-rolled coils, the weight typically ranges from 5 to 30 metric tons. Cold-rolled coils usually have weights between 2 to 20 metric tons. Coils with larger weights are commonly used for heavy-duty applications, while lighter coils are preferred for more delicate or precise applications. It is important to note that these are just general guidelines, and the actual coil diameter and weight combinations can be customized based on the specific needs of the customer. Different manufacturers and suppliers may offer a wide range of options to accommodate various industry requirements. Therefore, it's always advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your specific application.

- Q: hey... i don't need to change my strings, but i found a set of Bronze acoustic guitar strings by pure tone... i have a few questions on them:can i put them on a steel string guitar? i know i can't put nylon strings on... but i don't see why i can't put bronzethey are light gauze... i have no idea what my current gauze is, but i play in Dropped D tuning... so would the E/D string (6th) be too loose? finally, can you get strings designed to be played in Drop D?any help is apprechiated :D

- Are you talking about a steel guitar or a steel string guitar. Bronze strings won't work properly on a steel/lap steel/electric guitar but hey are designed to be played on an acoustic or acoustic electric steel string guitar. Light gauge strings are OK. However, the low E may be too thin if you tune that down to D. Another thing to consider is that the neck truss rod probably needs to be adjusted slightly if you change string gauge. This procedure is fast and simple if you know what you're doing. You should however leave it to someone else if you don't know how it's done. If you play all the time in drop D, I would probably use a set of medium strings or have a light set and use a heavier low E-string. Personally, I use drop D on my acoustics from time to time. I use light strings and find this to work well for me.

- Q: I'm kind of confused as to how the difference between a stainless steel and blued steel firearm is sometimes only $20 or so. Isn't stainless steel fairly more expensive to manufacture than plain carbon steel? Are some stainless steel firearms simply stainless steel finished with carbon steel underneath?

- Stainless guns are made out of stainless steel. Now there are also guns that are coated in nickel. Those are made of the usual gun steel. Stainless steel isn't really that much more expensive than normal steel when bought in large quanities.

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as the core component of electromagnetic relays. When an electric current passes through the coil, it generates a magnetic field which attracts or repels a metal armature, thus opening or closing the electrical circuit. This mechanism allows electrical switches to control the flow of electricity in various applications.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: What are the different methods of blanking steel coils?

- There are several methods for blanking steel coils, including shearing, laser cutting, and waterjet cutting. Shearing involves using sharp blades to cut the coil into desired shapes. Laser cutting utilizes a high-powered laser beam to accurately cut through the steel. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive materials to cut the coil. These methods offer different levels of precision, speed, and cost-effectiveness depending on the specific requirements of the blanking process.

- Q: I have a knife with 154cm steel on it and I always here that you should put oil on it to keep it from rusting but I am just wondering what kind of oil? And how do I apply it and do I just leave it on there?

- I don't know that steel, or what kind of knife it is, but unless it is a kitchen knife use the same thing you would use on a gun. Use an oil that dries, like Eezox, or use paste wax, or BreakFree, or Corrosion X.

Send your message to us

Hot Dipped Galvanized Steel Coil High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords