Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

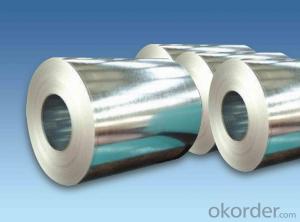

1.Description of Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard:

Hot dip galvanized steel coil products mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce industries ect.In construction industry, hot dip galvanized steel coil is mainly used to manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille, etc.

2.Specifications of Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard:

(1) Light industries use hot dip galvanized steel coil to make home appliance’s case, civil chimney, kitchen utensils, etc.

(2) Auto industry mainly use hot dip galvanized steel coil to produce corrosion resistant parts of cars

(3) Agriculture, animal husbandry, and fishery mainly use hot dip galvanized steel coil for food storage, meat and aquatic products’ freezing and processing equipment etc;

(4) In commerce, hot dip galvanized steel coil is mainly used as the equipments to store and transport materials, and packing implements.

3.Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard Images:

4.Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard Specification:

Specification(mm) | Reference length | Specification(mm) | Reference length |

0.18*1000 | 710m | 0.18*1200 | |

0.23*1000 | 553m | 0.23*1200 | 461m |

0.25*1000 | 509m | 0.25*1200 | 425m |

0.276*1000 | 472m | 0.276*1200 | 393m |

0.30*1000 | 424m | 0.30*1200 | 354m |

0.326*1000 | 398m | 0.326*1200 | 331m |

0.35*1000 | 364m | 0.35*1200 | 303m |

0.376*1000 | 335m | 0.376*1200 | 279m |

0.40*1000 | 318m | 0.40*1200 | 265m |

0.426*1000 | 303m | 0.426*1200 | 252m |

0.45*1000 | 285m | 0.45*1200 | 237m |

0.476*1000 | 271m | 0.476*1200 | 226m |

0.50*1000 | 254m | 0.50*1200 | 212m |

0.60*1000 | 212m | 0.60*1200 | 177m |

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery as they serve as a key component for constructing the machine's framework and structure. The coils provide durability, strength, and resistance to the machinery, ensuring its reliability and longevity in food processing operations.

- Q: I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- Weldable steel is a generic term for steel with low carbon content which makes it easy to weld, form, and machine. If you're looking for a knife blade material, you need either a stainless steel or a high carbon steel which is not at all weldable. The more carbon in steel, the better it responds to heat treatment like hardening, tempering, etc. Plus, the high carbon steel will hold an edge better. Hope this helped.

- Q: I want to know if Diamond is stronger than Steel.

- Diamond is harder than steel, as diamond can scratch steel, but steel can't scratch diamond. However, I think steel is more structurally stable than diamond. Besides, how can you afford diamond girders, not even mentioning the impossibility of making a diamond that large.

- Q: I have a steel plate 3' long x 2 wide x 3/16 thick. I have a 1/2 diameter hole with the center 3/4 from the end. Tensile strength is 38,000psi. A chain goes through the hole and is connected to a load. how does one determine how much tension the chain can have before it rips through the hole?

- Your title asks for the working load, yet your problem asks for the failure load (ripping the plate). These are two different things, since there must be a factor of safety on the failure load to get to the working load. The factor of safety varies from code to code and depending on what the plate/chain is being used for. The failure load would be the net cross section of the plate (after subtracting out the hole) x the strength of the plate. In this case it would be (2 - .5)*3/16*38000psi=10,687.5 lbs You would also need to check the strength of the chain to make sure that it doesn't break before the plate.

- Q: What is the process of pickling and oiling steel coils?

- To ensure the quality and protection of steel coils, a series of steps are undertaken in the process of pickling and oiling. The first step involves pickling, wherein impurities and scale are removed from the surface of the steel coil. This is achieved by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which effectively dissolves any oxides, rust, or contaminants present on the surface. This step is critical as it readies the steel for further processing and safeguards against potential defects or corrosion. Following pickling, the steel coils are rinsed with water to eliminate any residual acid and then dried. Once they are clean and dry, a layer of oil is applied to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating acts as a barrier, preventing rusting or oxidation before the steel undergoes further processing or is utilized in various applications. The oiling process can be executed through various methods. One common approach is to apply the oil using a roller or brush, ensuring an even coating across the entire surface of the coil. Alternatively, the coils can be passed through a bath or spray chamber where the oil is administered. The choice of oil depends on the specific requirements of the steel and its intended use, with options ranging from mineral oil and synthetic oils to specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is crucial to handle the coils with care to avoid damaging the oil coating and compromising the corrosion protection it provides. Overall, the pickling and oiling of steel coils are indispensable steps in the steel manufacturing process. They ensure the quality, cleanliness, and protection of the steel, thereby prolonging its lifespan and enhancing its performance in various applications.

- Q: I have several stainless steel utensils and appliances, so when I put them through the dishwasher some of them are rusting, I think its because my current dishwashing soap is harsh, what is some great dishwashing soap that will clean my dishes and not be so hard on my stainless steel appliances and utensils?

- Jan is correct. You need to have some nickel in the stainless steel to prevent rusting, like 18/10 which has 10% nickel alloy in the steel.

- Q: What is the standard thickness of steel coils?

- The standard thickness of steel coils can vary depending on the specific application and industry requirements. However, in general, steel coils are typically available in a range of thicknesses between 0.5mm to 10mm. The desired thickness of a steel coil is determined by factors such as the intended use, structural requirements, and manufacturing processes. Thicker steel coils are often used for heavy-duty applications that require greater strength and durability, while thinner coils are suitable for lighter applications where flexibility and weight reduction are important. It is important to consult industry standards and specific project requirements to determine the appropriate thickness for steel coils in any given application.

- Q: Which of the two are better for exhaust manifolds, im guessing the stainless steel right?

- For strength, cast iron (that's why OEM exhaust manifolds are made out of it). For performance, stainless steel. For one, stainless steel headers are lighter than cast iron ones. Then they come in multiple arrangements, (4-2-1 or 4-1 for 4 cylinder motors). The down fall is strength. Hit a pot hole with the collector of a stainless steel header. It's going to have a nice dent in it.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Steel coils can be damaged easily when they are stored or transported. They are quite heavy and can easily become deformed, bent, or scratched if they are not handled properly. It is also important to stack and secure them correctly during transportation to prevent them from shifting or moving, as this can also lead to damage. Moreover, the steel coils can be affected by moisture, extreme temperatures, or corrosive substances, which can compromise their quality. Therefore, it is vital to handle, store, and transport steel coils with great care to minimize the chances of damage and maintain their overall integrity and usability.

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- I believe you are asking about two vastly different processes. This is science so, if you want a specific answer, you have to ask specific questions. VERY Basically... 1) Pig iron production works by melting iron and pouring it into molds that produce ingots called pigs. 2) fraction distillation separates different substances (typically starting in liquid form) by controlled heating so, since different substances boil at different temperatures, the vapors can be captured selectively.

Send your message to us

Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords