Hot-dip Zinc Coating Steel in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

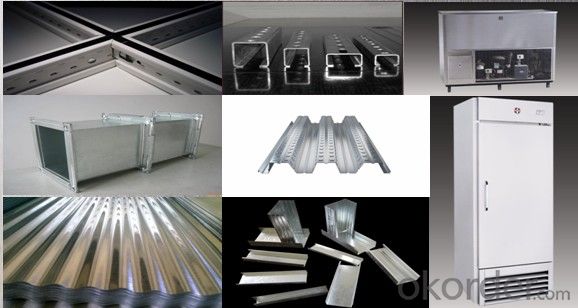

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of shock absorbers?

- Steel coils are used in the manufacturing of shock absorbers as they provide the necessary spring force to absorb and dampen the impact from road irregularities. The coils are designed to compress and expand under pressure, allowing the shock absorber to absorb and dissipate the energy generated during vehicle movement, resulting in a smoother and more controlled ride.

- Q: How do steel coils contribute to fire resistance in buildings?

- Steel coils contribute to fire resistance in buildings primarily due to their material properties. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. It has a high melting point, which helps it retain its structural integrity even under high temperatures. Additionally, steel coils are often used as structural elements in building construction, providing strength and stability to the overall structure. This helps prevent the collapse of the building in case of a fire, providing occupants with more time to evacuate safely.

- Q: What is the difference between cold rolled strip and cold rolled steel coil?

- Cold rolled steel strip: the width is below 900mm! Cold rolled steel coil: the width is above 1000mm! Materials and purposes are not very different, basically the same!

- Q: I know aluminum is lighter but I'm looking at a 01 bianchi grizzly mountain bike which is steel. I used to ride a specialized stumpjumper m4 which was aluminum. It was quite light so I don't know if I'll like a bit heavier bike but overall what is better from those who have had both?

- I've ridden steel, alum, Ti and carbon. I like 'em all. It all depends of craftsmanship and design IMHO. Really, a light steel frame is only about 1 to 1.5 lbs heavier than other super light frames. Steel has a rep for being heavy and most of that comes from being a heavier duty frame and being spec'ed with heavier parts. With that being said I have 2 alum and 1 carbon framed bikes now. I owned several steel bikes in my day, loved 'em too. I like light and if you're a weight weenie too you may not want a heavier bike regardless of material. The Stumpjumper is a sweet light bike. If the Grizzly is up to your specs give it a go. Thats how you experience life. Try something different. You'll like the feel of steel, as of the bike? Only you will know if you like it or not.

- Q: i would like to know of any companies who buy shredded scrap steel

- We are one of the biggest steel mills in Asia. Under our group, we have steel mills in Thailand and Bangladesh. On the monthly basis, we purchase steel scrap HMS1/2 80:20 and the shredded ISRI210/211, ISRI211 by bulk and 20' container to Thailand and Bangladesh. Due to the limitation of our existing shredded steel scrap supplier, we need to get more supply of the shredded. Please contact us or offer us of ISRI 210/211 or ISRI211 CFR Chittagong, Bangladesh with 500mt - 2000mt per shipment by 20' container. If any questions, please feel free to contact us.

- Q: What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including galvanizing, painting, powder coating, and zinc coating. These treatments help protect the steel from corrosion and improve its durability and appearance.

- Q: I have a white gold engagement ring, and to be special I thought I'd get a plain band from Tiffany's--in stainless steel. Can stainless steel be worn with white gold or will there be a difference in the color or texture? I'm not planning on getting them soldered together, but I don't want it to be noticeable that they are different metals. Does anyone have experience in this subject?

- I didn't know Tiffany's sold stainless steel rings. I think the colour might match, but the texture wouldn't really (from looking at all the stainless steel around my kitchen. The only way to know for sure is to go to Tiffany's and try it on with your ring. Why not consider a white gold band from Tiffany's? I don't know what the price difference would be on that. But you can get a white gold for around $250 from TCo.

- Q: would you consider steel a flexible substance...i am debating this with my coworkers.Thanks,

- Yes, looking at it from an engineering standpoint. Depending on it's shape it can be used for many applications where flexibility is important. Steel springs for example, or guitar strings. Whenever you're debating these kinds of matters, it is important to keep in mind that the use of a material depends on the shape, the size and the weight it's going to be used in. A big block of steel will be used in a different manner as a piece of steel wire.

- Q: How are steel coils used in the production of automotive frames?

- Steel coils are used in the production of automotive frames as they are rolled into sheets and then cut and shaped to form the necessary components of the frame. The coils provide the raw material that is strong, durable, and able to withstand the structural demands of the vehicle.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are typically protected from mechanical damage through the use of various packaging materials such as wooden crates, steel frames, or protective plastic wraps. These measures ensure that the coils remain intact and safeguarded during transportation, handling, and storage, minimizing the risk of any potential mechanical damage.

Send your message to us

Hot-dip Zinc Coating Steel in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords