Hot-Dip Galvanized Steel Thickness 0.6mm Width 1800mm Max

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

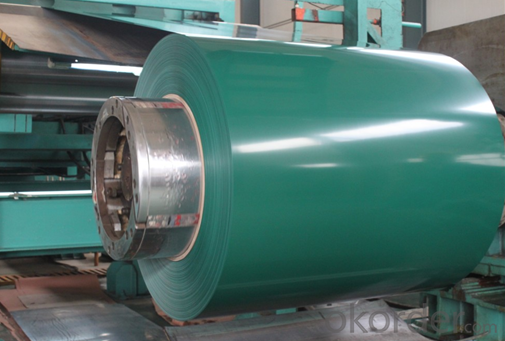

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Specifications of Pre Painted Galvanized Steel Coil:

1) Capacity: More than 20, 000 tons per month for PPGI coil product manufacture

2) Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

3) Grade: SGCC CGCC, DX51D, TDC51D, ASTM A653 CS TYPE, S280GD, S350GD, G550

4) Thickness: 0.15mm-1.5mm

5) Zinc coating weight: Z60-275G/M2, G30-G90

Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

6) Width: 600mm-1250mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm or according to the customer's request

7) Coil ID: 508mm-610mm

8) Coil Weight: 3-6mt, or according to the customer's request

9) Color: RAL, or customer sample color

RAL9016, RAL9002, RAL5015, RAL5002, RAL3000, RAL3020, RAL3009, RAL6005, RAL8017 etc.

10) Color coating type: PE, PVDF, SMP, HDP, etc.

Regular Polyester, Silicon Modified Polyester, Polyvinylidene Floride, PVDF, Super Low Gloss Polyester

11) Surface protection: PVC film protected according to customer requested

12) Min trial order: 25 tons for 1X20' per delivery

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

FAQ

1. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: How are steel coils processed for different finishes?

- Various methods can be utilized to achieve different finishes on steel coils. One of the most commonly used is known as coil coating. This process involves several steps, including cleaning, priming, coating, and curing the steel coil to obtain the desired finish. To begin, any contaminants on the surface of the coil are removed, followed by the application of a primer to improve adhesion. Finally, a specific paint or coating material is applied to the coil. The coated coil is then subjected to high temperatures to ensure proper adhesion and durability. Another method for processing steel coils is galvanization. This technique involves coating the steel coil with a layer of zinc to protect it from corrosion. Galvanization can be achieved through hot-dip galvanization, where the coil is immersed in molten zinc, or electro-galvanization, where a thin layer of zinc is electroplated onto the coil. The resulting galvanized finish offers exceptional corrosion resistance and can be further processed for various aesthetic finishes. Furthermore, different surface treatments can be employed to achieve desired finishes on steel coils. These treatments may include pickling, which utilizes an acid solution to eliminate scale and impurities from the coil, or mechanical treatments like brushing or grinding to create a specific texture. Following these surface treatments, a protective coating or paint can be applied to enhance the appearance and durability of the coil. In conclusion, achieving various finishes on steel coils necessitates a combination of cleaning, coating, curing, and surface treatments. The selection of specific methods depends on the desired finish and the intended application of the steel coil.

- Q: How are steel coils used in the production of household goods?

- Steel coils are an essential component in the production of various household goods. These coils are typically made from high-quality steel and are manufactured to specific dimensions and thicknesses to meet the requirements of different products. One of the primary uses of steel coils in household goods production is in the manufacturing of appliances such as refrigerators, washing machines, and dishwashers. The coils are used to create the body and framework of these appliances, providing strength, durability, and stability. Additionally, steel coils are often used in the production of smaller household appliances like toasters, blenders, and coffee makers. Furthermore, steel coils are also used in the production of furniture, particularly in the manufacturing of metal frames for chairs, tables, and cabinets. These coils provide the necessary support and structural integrity to the furniture, ensuring long-lasting durability. Another significant application of steel coils in household goods production is in the production of shelving units and storage solutions. Steel coils can be shaped and formed to create sturdy shelves and racks that can hold heavy items and withstand regular use. These shelves are commonly used in kitchens, garages, and storage rooms to organize and store various household items. In summary, steel coils play a crucial role in the production of household goods. They are used to create the framework, structure, and support for appliances, furniture, and storage solutions. Their strength, durability, and versatility make them an ideal material for manufacturing a wide range of household products that are designed to withstand everyday use.

- Q: Can steel coils be rewound?

- Yes, steel coils can be rewound.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- My work boots are steel caps i ride to work and home in them. I also wear them when I'm too lazy to change into my proper boots.I don't see any dramas with you wearing them they do come in handy for dogs that try to latch onto you. Ride safe.

- Q: What are the different grades of steel used in coils?

- There are several different grades of steel used in coils, including low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, durability, corrosion resistance, and formability.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Hello, the shutter door material mainly galvanized steel plate, color steel plate, aluminum alloy, stainless steel, PVC soft board, PVC soft door curtain.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- We galvanize steel to protect and prevent steel from rusting or corrosion. Rusting, for the most part is a layman's term that has been used exclusively to describe the chemical OXIDATION reaction of steel or iron with oxygen forming a reddish brown substance called rust. Zinc metal coating also oxidizes but does not form the reddish brown rust. Instead, it forms an oxide, just like the rust, which is iron oxide. The protection created by zinc is because it is more reactive to oxidizers, than steel or iron. Thus, the oxidizer will react with Zinc first before it will react with Iron, hence protecting iron. If the zinc is fully reacted then iron is next. BUT, the zinc oxide formed on the surface of the steel or iron is no longer reactive to oxygen and also creates a good physical barrier so that oxygen will not have chance to even have contact with the underlying steel. Isn't that neat! Here is chemistry at one of its useful best.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

- Q: How are steel coils inspected for width variations?

- Steel coils are inspected for width variations by using a non-contact laser measurement system. This system measures the width of the coil at various points along its length, ensuring that it meets the required specifications.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- Most of the 300 series stainless metals are not magnetic, but if it is cast, it is magnetic. Welds are considered casting, so the welds are magnetic even though the items that are welded together are not. The 400 series stainless may have a few types that are magnetic. I suppose generally the hardenable factor has a bearing if you consider that 400 series can be hardened more readily than the 300 series. Source: Working in metal fabrication shops.

Send your message to us

Hot-Dip Galvanized Steel Thickness 0.6mm Width 1800mm Max

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords