Hot-Dip Galvanized Steel Sheet with Best Qualiy Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

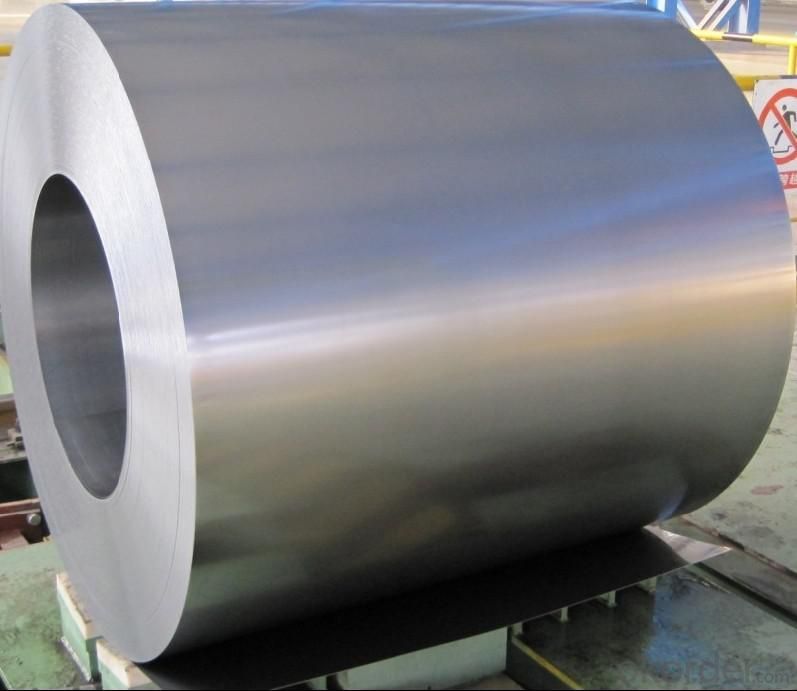

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

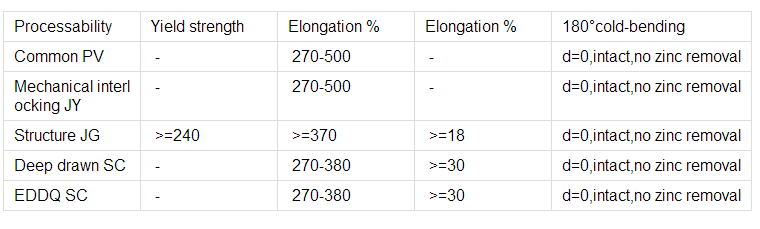

4.Hot-Dip Galvanized Steel Sheet Specification

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the diffrent Aluminized steel Type 1. stainless steel 409 430?

- Stainless steel 400 Series—ferritic and martensitic chromium alloys Type 409—cheapest type; used for automobile exhausts; ferritic (iron/chromium only) Type 430—decorative, e.g., for automotive trim; ferritic. Good formability, but with reduced temperature and corrosion resistance. Today, almost all bulk metal materials that are referred to loosely as aluminium, are actually alloys. For example, the common aluminium foils are alloys of 92% to 99% aluminium. Aluminized steel Type 1: 1xx.x series are minimum 99% aluminium

- Q: How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel is a highly conductive material, allowing for efficient heat transfer. This means that appliances with steel coils, such as refrigerators or air conditioners, can cool or heat up faster, reducing energy consumption. Additionally, steel coils are durable and have excellent heat retention properties, meaning that once the desired temperature is reached, the coils can maintain it for longer periods without consuming additional energy. This helps appliances to operate more efficiently and save on electricity usage.

- Q: What are the common coil grades available for steel coils?

- Steel coils come in different grades, each with its own distinct properties and uses. Some commonly used grades include: 1. HRC (Hot Rolled Coils): These coils are made by heating a steel slab to its recrystallization temperature and rolling it into a coil. HRC coils are known for their excellent weldability and formability, making them suitable for various applications like construction, automotive manufacturing, and general engineering. 2. CRC (Cold Rolled Coils): CRC coils are produced by further processing HRC coils through cold reduction, which involves passing the steel through rollers at room temperature. CRC coils have a superior surface finish and dimensional accuracy, making them ideal for applications that require a smooth and uniform appearance, such as automotive body panels, appliances, and electrical equipment. 3. GI (Galvanized Coils): GI coils are created by coating regular carbon steel coils with a layer of zinc through a hot-dip galvanizing process. This provides excellent corrosion resistance, making GI coils suitable for outdoor applications like roofing, fencing, and structural components. 4. Stainless Steel Coils: Stainless steel coils are made from different grades, with the most common being austenitic (such as 304 and 316) and ferritic (such as 430). Stainless steel coils offer excellent corrosion resistance, high temperature resistance, and aesthetic appeal, making them widely used in industries like food processing, chemical processing, and architecture. 5. EG (Electro-galvanized Coils): EG coils are similar to GI coils, but the zinc coating is applied using an electrolytic process instead of hot-dipping. EG coils have a thinner and smoother zinc layer, making them suitable for applications that require a brighter and more aesthetic appearance, such as automotive parts, appliances, and decorative items. These are just a few examples of the coil grades available for steel coils. The choice of the right grade depends on factors like the intended application, required mechanical properties, and desired aesthetics. It is important to seek guidance from steel suppliers or industry experts to determine the most suitable coil grade for a specific application.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. However, it is typically measured in millimeters or inches, ranging from a few tenths of a millimeter to several millimeters.

- Q: What are the different methods of oiling steel coils?

- There exist multiple techniques for oiling steel coils, each possessing unique benefits and applications. Some commonly employed methods are as follows: 1. Immersion or bath oiling: This technique entails immersing the steel coils in an oil bath, typically passing them through a series of rollers to ensure an even and complete coating. Bath oiling is a cost-effective and efficient method for large-scale production as it allows for simultaneous oiling of multiple coils. It is commonly utilized for hot-rolled coils. 2. Roll-on oiling: As suggested by the name, roll-on oiling involves applying oil to the surface of steel coils using rotating rollers. This approach guarantees uniform oil distribution and is suitable for both cold-rolled and hot-rolled coils. Roll-on oiling is often preferred when precise control over the amount of oil applied is necessary. 3. Spray oiling: Spray oiling involves applying a fine mist or spray of oil to the coils using specialized nozzles or sprayers. This method allows for targeted application, making it suitable for specific areas or sections of the steel coils. Spray oiling is commonly employed for precision or specialty coils where controlling the oil quantity is crucial. 4. Electrostatic oiling: Electrostatic oiling entails applying a charged mist of oil particles to the steel coils. The coils are given an opposite charge, causing the oil particles to be attracted and adhere to the surface. This method ensures an even and controlled distribution of oil, minimizing waste, and reducing environmental impact. Electrostatic oiling is commonly used for high-quality or high-precision applications. 5. Brush or roller oiling: This technique involves manually applying oil to the coils using brushes or rollers. It is typically utilized for smaller-scale operations or when precision is required in specific areas. Brush or roller oiling allows for close control over the amount of oil applied. The selection of the oiling method depends on various factors, including the type of steel, desired level of oil coverage, production volume, and cost considerations. Each method possesses its own advantages and limitations, and manufacturers often choose the most suitable technique based on their specific requirements and objectives.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: What processes and materials are used in the production of chrome steel

- well, save up some more $$. I wouldnt feel safe on a $120 mountain bike. My advice would be to invest in something that's a little more money. Also, why do you want a steel frame? Aluminum frames today are made from 7005 alloy, and stack up very well compared to the durability of steel. Plus, they wiegh alot less. Nowadays, youll only find steel on a cheap walmart bike, ir a top notch downhill bike made for extream offf road conditions.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- Steel is better. Acrylic is porous so isn't as suitable for piercing jewellery as steel. Steel can also slide through easier for some people, acrylic isn't quite as smooth. For tapers it doesn't make a huge deal of difference as they're only passing through your ear briefly, not being worn as jewellery, but if they're close in cost anyway then go for the steel. And the plugs you insert after putting the taper through should always be steel, titanium or glass until your stretch has healed.

- Q: Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- There is a chemical that is used presently that is sprayed onto steel beams called Monocoat. Its a form of insulation that gives steel protection for up to 2 hours I think. Hope that helps!

Send your message to us

Hot-Dip Galvanized Steel Sheet with Best Qualiy Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords