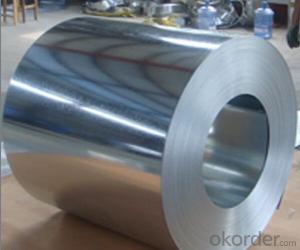

Hot Dip Galvanized Steel in Coil in Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Galvanized Steel Coil gets coated in layers of zinc because rust won't attack this protective metal. The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel. For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Superiority:

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Construction field ,ships building industry ,Petroleum and chemical industries ,war and electricity industries ,food processing and medical industry, boiler heat exchanger, machinery and hardware fields

Electrical Appliance:refrigetator.washer,switch cabinet,etc

Furniture:central heating slice, lampshade, etc

Product Specification:

Material:SGCC,DX51D,Q195

Thickness: 0.3-3.0mm

Width: 600-1500mm

Inner Diameter: 508mm, 610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Steel grade & Standard: JIS G3302 SGCC

Spangle: Normal spangle, large spangle, small(min) spangle, zero spangle

FAQ:

1.How about the package for the Hot Dip Galvanized Steel in Coil?

Usually Standard export seaworthy package: waterproof paper+steel trip packed+wooden case seaworthy package

Package:Covered with waterproof-paper, strapped by strips. Standard seaworthy export package:4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

2. Can I know the production period of the goods?

Usually it need 20 days for 25tons in one container. We can produce 300 tons per day but we need to arrange the production in advance.

3. How about the label, could you make the label according to pour requirements?

Usually we use the MILL label, but if you need special form we can make.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- A kitchen range finished in stainless steel looks professional and clean. Stainless steel stove requires a bit more cleaning than a traditional stove. Use an oil based product. Baby oil or WD40 are the products of choice for many people. You don’t want to put the oil directly onto the appliance, instead just pour some onto the cloth and wipe down the appliance. Routine maintenance on your stainless steel stove is the best way to keep the surface steel clean as well as scratch free.

- Q: Should I stick with the all steel kit over the acrylic tapers and steel plugs? or would the acrylic be ok? I keep hearing that steel is the best and acrylic can cause problems. I just want to do it correctly and take my time with it, no rushing.thanks

- I haven't heard anyone complain about using acrylic so I don't see why it would be a problem. Either would be fine. I prefer acrylic myself but it really doesn't matter.

- Q: How are steel coils used in the production of industrial storage tanks?

- Steel coils are commonly used in the production of industrial storage tanks as they provide the necessary strength and durability. The coils are processed and formed into tank shells, which are then welded together to create the tank structure. This ensures that the tank is capable of withstanding the pressure and weight of the stored materials.

- Q: How are steel coils inspected for oil or rust residues using chemical analysis?

- Steel coils can be inspected for oil or rust residues using chemical analysis techniques. One of the commonly used methods is Fourier transform infrared spectroscopy (FTIR). In this technique, a small sample of the steel coil is taken and subjected to infrared radiation. The infrared spectrum obtained is then analyzed to identify the presence of specific chemical bonds that are characteristic of oil or rust residues. For detecting oil residues, a common approach is to use the peak at around 2920 cm-1 in the FTIR spectrum, which corresponds to the C-H stretching vibration in hydrocarbon chains. If this peak is observed, it indicates the presence of oil residues on the steel coil. To identify rust residues, the FTIR spectrum is analyzed for the presence of characteristic peaks corresponding to iron oxide or hydroxide compounds. For example, the presence of a peak at around 560 cm-1 suggests the presence of iron oxide (FeO) or iron hydroxide (Fe(OH)3). In addition to FTIR analysis, other chemical analysis techniques can also be utilized, such as X-ray fluorescence spectroscopy (XRF) or energy-dispersive X-ray spectroscopy (EDX). These techniques can provide elemental composition information, allowing for the identification of specific elements associated with oil or rust residues, such as carbon or iron. Overall, the chemical analysis of steel coils for oil or rust residues provides a reliable and accurate method to ensure the quality and cleanliness of the coils before further processing or usage.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try a local Fastenal store, they can order it for you by the sheet. If that doesnt help, then try a welding or fabricating store.

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- It will permanently ruin the guitars neck. Acoustic guitars have an adjustable metal rod in them called a “Truss Rod” that allows the neck to withstand steel string tension. How about putting on high tension nylon strings ?

- Q: How are steel coils inspected for coil set using deflection measurement?

- Steel coils are inspected for coil set using deflection measurement by subjecting the coil to a controlled force and measuring the amount of deflection or bending that occurs. This is typically done by placing the coil on a support system and applying a known load or weight onto the center of the coil. The deflection or displacement of the coil is then measured using sensors or devices that can accurately detect any changes in the coil's shape. This measurement helps to identify any potential coil set, which is a condition where the coil retains a curved or bent shape even when unrolled.

- Q: What are the different types of steel coil grades?

- There are several different types of steel coil grades, including hot rolled coil (HRC), cold rolled coil (CRC), galvanized coil (GI), galvannealed coil (GA), and stainless steel coil.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials.

- Q: How are steel coils inspected for width variations?

- Steel coils are inspected for width variations by using a non-contact laser measurement system. This system measures the width of the coil at various points along its length, ensuring that it meets the required specifications.

Send your message to us

Hot Dip Galvanized Steel in Coil in Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords