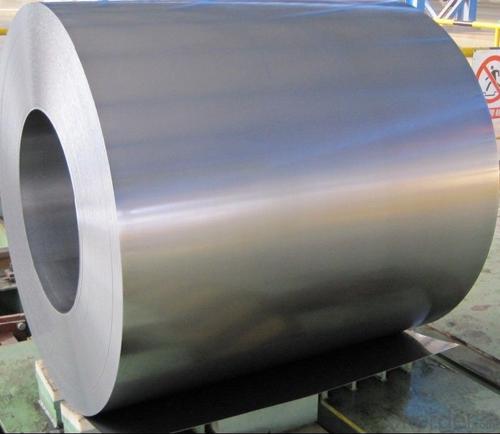

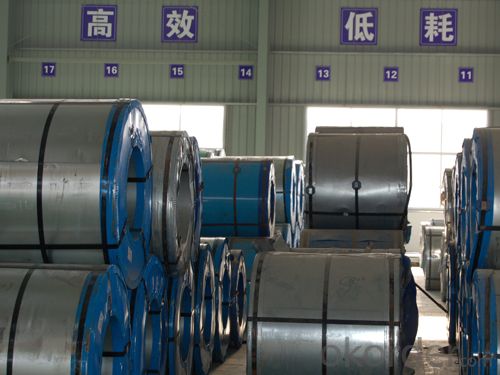

Hot Dip Galvanized Steel Coil Minimum Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the manufacturing process and the specific requirements of the industry. However, in general, steel coils can have a maximum width of around 2,200 millimeters (86.6 inches).

- Q: I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Regardless of who makes the knife, you might look at stainless steel instead of the better tool steels like O2,M2 or D2...stainless takes more abuse and neglect than the others do.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Baking soda mixed with liquid dish soap can make a good paste to gently rub on stains. Be sure to rinse the stainless steel surface thoroughly, and towel dry. If the stains still remain you can try vinegar. Remember to thoroughly rinse and towel dry. If stains still remain I recommend trying a stainless steel cleaner and polisher. Barkeeper's Friend is a good powder formula that can clean without scratching. Be sure to follow the directions, rinse thoroughly, and towel dry. These methods should help remove the discolorations

- Q: If steel content is too cheap, what content should I be looking for? I don't think I could find something like a VG-10 here...

- Confusion Sucks. Why are you going into all this crap over the content of steel in the knives, your only confusing yourself. I recommend you go to a chef's supply or a good store that sells chef's utensil's and knows what he is talking about, and look at something that is comfortable for you. Chris

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are typically inspected for damage during transportation through visual inspections, where trained personnel carefully examine the coils for any visible signs of dents, scratches, or other forms of physical damage. Additionally, specialized equipment such as ultrasonic testing or magnetic particle inspection may be used to identify any hidden or internal defects in the coils. These inspection methods ensure that any potential damage is detected early on, allowing for prompt repairs or necessary precautions to minimize any further harm.

- Q: Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums by being cut into sheets and then rolled into cylindrical shapes, which form the body of the drum. The coils provide the necessary strength and durability required for the drums to hold and transport various materials safely.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless can oxidize over time but it doesn't look much like regular rust. Depending on the exact composition of the stainless alloy in question and what other materials are in contact with it, that's more or less of an issue. In constant contact with skin oils and gentle polishing from contact with skin and clothing, watches rarely rust regardless of what they're made of, I think you have nothing to worry about. Note: for future reference, bleach is absolute hell on stainless. It's bad enough on steel, worse on stainless. Especially because you have this idea that stainless is more or less impervious, when in reality it just isn't.

- Q: which elements are alloyed to make stainless steel?A Fe, CB Fe, MnC Fe, NiD Fe, CrE Fe, Cr, Ni

- E. Stainless steel is mainly comprised of Cr and Ni. Steel is an alloy composed mainly of iron. On a side note, Carbon is not really in stainless steel and it is only less than .1%

- Q: What are the common processing defects in steel coils?

- The common processing defects in steel coils include surface imperfections such as scratches, dents, and stains, as well as edge wave, coil set, camber, and crossbow. Other defects may include coil breaks, oil spots, rust, and uneven thickness or width variation.

Send your message to us

Hot Dip Galvanized Steel Coil Minimum Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords