EXCELLENT HOT-DIP GALVANIZED/ ALUZINC STEEL in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:AZ30-AZ150

SPANGLE:Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7m

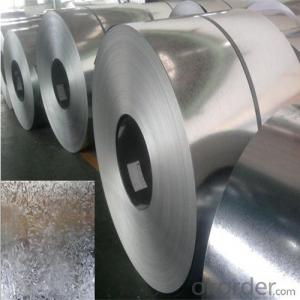

Applications of our Galvalume Coil:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are an essential component in the production of storage shelves. These coils are typically made from carbon steel and undergo a series of processes to shape them into the desired form. The first step in using steel coils for storage shelves is to unroll and flatten the coil. This is done using a machine called a decoiler, which unwinds the coil and feeds it through a series of rollers to flatten the metal. Once the coil is flattened, it is ready for further processing. Next, the flattened steel is cut into specific lengths using a shearing machine or a saw. These cut pieces are then bent and shaped into the appropriate dimensions for the storage shelves. This bending process is typically done using a press brake or a roll former, which applies pressure to the metal to create the desired shape. Once the steel has been shaped into the proper dimensions, it is welded together to form the structure of the storage shelf. This welding process ensures that the shelves are strong and durable, capable of supporting heavy loads. After the welding is complete, the storage shelves may undergo additional processes such as surface treatment or coating to enhance their appearance and protect them from corrosion. These treatments can include processes like powder coating, galvanization, or painting. Overall, steel coils play a crucial role in the production of storage shelves. They provide the raw material from which the shelves are made, and their versatility allows for a wide range of shapes and sizes to be created. The strength and durability of steel make it an ideal choice for storage shelves, ensuring that they can withstand heavy loads and provide long-lasting storage solutions.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, common dimensions for railway steel coils typically range in thickness from 1.5mm to 25mm and in width from 600mm to 2000mm. The inner diameter of the coil is typically around 508mm, while the outer diameter can range from approximately 900mm to 2000mm.

- Q: Please people suggest me how can I select external finishing for Steel Building as there is a wide range of choice available.

- Nowadays, okorder /

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- carbon will rust.. stainless doesn't rust unless it touches carbon so its definitely not stainless. Since its only 1.7% its extremely unlikely that it will rust unless you leave it outside for extreme long periods of time. Either way you should take care of it. Put it in the garage or something but you don't have to dry it after every use.

- Q: What exactly is surgical stainless steel made of (metals)? Does it contain nickel? If so, what % does it usually contain? I am deciding between surgical stainless steel piercings or titanium. Both same price and looks. I want to know which one is more hypo-allergenic and generally nickel free.

- surgical stainless steel is an austenitic steel containing 18-20% chromium and 8-10% nickel. and some proportion of molybdenum. The word 'surgical' refers to the fact that these types of steel are well-suited for making surgical instruments: they are easy to clean and sterilize, strong, and corrosion-resistant. The nickel/chrome/molybdenum alloys are also used for orthopaedic implants as aids in bone repair, and as a structural part of artificial heart valves and other implants. However, immune system reaction to nickel is a potential complication. In some cases today titanium is used instead in procedures that require a metal implant which will be permanent. Titanium is a reactive metal, the surface of which quickly oxidizes on exposure to air, creating a microstructured stable oxide surface. This provides a surface into which bone can grow and adhere in orthopaedic implants but which is incorrodible after implant. Thus steel may be used for temporary implants and the more expensive titanium for permanent ones

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: I juuuust got a new stainless steel sink only 5 months ago, and it already has a couple rust spots on it.What caused this?!

- This is usually surface rust caused from other non-stainless objects coming in contact with the sink. It is a stain, more than actual rusting of the sink. Barkeepers Friend works well for cleaning stainless steel. Find it in the cleaning aisle of most larger stores.

- Q: Can steel coils be stored in a humid environment?

- Steel coils should not be stored in a humid environment as it can lead to corrosion and damage to the steel.

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery to create various components and parts such as frames, brackets, and structural supports. The coils are typically cut, shaped, and welded to form these components, providing strength, durability, and stability to the agricultural machinery.

Send your message to us

EXCELLENT HOT-DIP GALVANIZED/ ALUZINC STEEL in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords