Hot Dip Galvanized Joint Pin 36*1.0*235 for Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

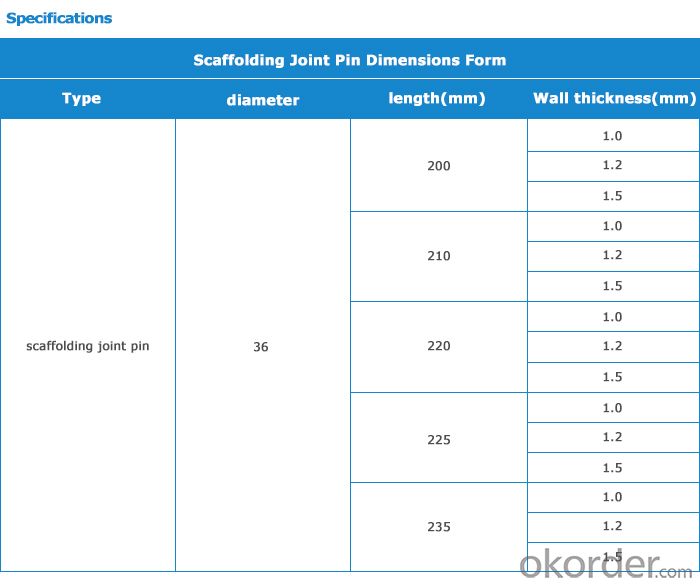

Description of Hot Dip Galvanized Joint Pin 36*1.0*235 for Scaffolding

Material :Q195 steel

Surface treatment :Galvanized

Package :By pallet

Diameter :36mm

Hot Dip Galvanized Joint Pin 36*1.0*235 for Scaffolding Futures:

Scaffolding joint pin connects rods up to down and make sure standard uniform stressed and structure stabilized.

Rods cost less steel with reasonable use of material. This stable structure is cost-saving in steel consumption and high in bearing capacity.

Standard size and reasonable structure

Beautiful and durable

Easy for assemble and dismantlement

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Exterior wall scaffold construction plan?

- Vertical pole:Double row scaffolding pole, pole top high eaves 1.5m structure. Single tube base for vertical rod bottom. The vertical rod joint is connected with a butt fastener, and the vertical rod and the large cross bar are connected by a right angle fastener. When the joint is staggered, the two adjacent column joints are avoided to be in the same span, and the distance between them is not less than 50cm; the distance between each joint center and the main node is not greater than 60cm.

- Q: i already found the force in rope 2 but im not getting the force in rope 1.

- The tension in the two vertical ropes must sum to 700N in order to balance the window washer. EDIT. In order to find the answer for each rope, I need to know how long the scaffold is and where the window washer is standing. EDIT. Taking moments about the end nearest to window washer. T1*3.044 = 298.6*1.522 + 700*1.51 ----> T1 = 496.54 N (2. d. p.) Taking moments about the other end. T2*3.044 = 298.6*1.522 + 700*1.534 ----> T2 = 502.06 N (2. d. p.) T1 + T2 = 496.54 + 502.06 = 998.6 = 700 + 298.6 as required.

- Q: hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- Dab it with tissue until it stops, Try not to play with it too much and if you need to touch it, ALWAYS wash your hands before doing so. Also do hot salt water soaks (as hot as you can stand) twice a day and it'll heal nicely in no time :)

- Q: First of all, is it painful? Obviously it will be painful I know, but is it severe?Also, what cleaning solutions/products do I need to minimise the risk of infections?And what type of bar should I get? I've heard that Bioplast and PTFE allow for better flexibility and therefore quicker healing, but wouldn't a flexible bar lead to mis-alignment on the two pierced holes? If this is so, what types of steel are safe for initial piercings?Thanks c:

- Ask how long they have been piercing and what certifications (if any) they carry, additionally verify close by regulations to ascertain if any are required. additionally ask how generally they spore verify their autoclave and while it grew to become into accomplished final time. Ask to ascertain a portfolio of HEALED piercings, exceptionally pictures of in spite of piercing you try to get.

- Q: Im in college football, I would be puting on and taking off my helmet, I usually keep it on though during practice...but would it be wise for me to get an industrial piercing a couple months before 2 a days and the football season...would the sweat maybe infect my ear, but I am a very clean guy? thanks, if you have an answer it will help my decision.....

- id leave it. theyre hard to heal nyway,and the added pressure of the helmet and the sweat and the possibility of getting hit in the head and knocking the piercing....well, i wouldnt risk it

- Q: there is also shrubs and trees planted on the base of the wall and 14 feet from it

- A little late to be asking that question if you already have the contract, isn't it?

- Q: How to maintain the scaffold after use

- Where the bending, deformation of the rod should be straightened, damaged components should be repaired before they can be stored in storage, or should be changed.

- Q: Cells from an animal's muscles are processed with chemicals and they grow. The cells are transferred to a metal scaffold and are stimulated physically. In a few months, you have a big block of meat which can be ground and cooked. What do you have to add? Does this innovation mean the price of meat will become a very minor expense?

- Sounds weird. When eaten I wonder how this experiment would affect the human body. It just might turn normal people into Liberals. If that's the case then I don't want anything to do with it.

- Q: hi, i already have my cartlidge pierced on my right ear and thinking about getting a scaffold piercing on my left ear. will a scaffold piercing hurt more than my cartlidge piercing,,less,,or about the same???thanks answers apprecietedhope =] xx

- Several people have told me it hurts about the same. I do not have one, sorry couldn't be more help than that.

- Q: What are the safety requirements for the dismantling of construction scaffolding

- (3) prior to the dismantling of scaffolding, the scaffolding should be retained on the material, debris and other clean, and should be removed by the removal of mechanical equipment, electrical and other pipelines, such as demolition, or to be protected.(4) the dismantling of the scaffolding should be unified command, should be approved by the construction plan, the requirements of the work instructions, from top to bottom in the order of the upper and lower levels are strictly prohibited demolition operations.

Send your message to us

Hot Dip Galvanized Joint Pin 36*1.0*235 for Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords