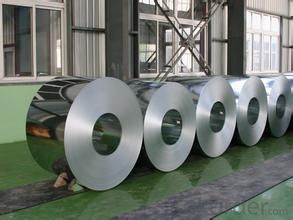

Hot-Dip Galvanized/ aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Service:

1,on time delivery

2,high quality with competitive price

3,good service

4,long-term cooperation

5, rely on honors

Images:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

- Q: What is a steel coil?

- A steel coil is a long, continuous strip of flat-rolled steel that is wound into a coil shape. It is typically used in various industries, such as automotive, construction, and manufacturing, for making a wide range of products, including pipes, tubing, roofing, appliances, and automotive parts.

- Q: What are the common applications of cold-rolled steel coils?

- Due to its exceptional qualities, cold-rolled steel coils find a wide range of common applications across various industries. The automotive industry extensively uses these coils to manufacture car parts like body panels, chassis components, and structural reinforcements, benefiting from the high strength and excellent formability of cold-rolled steel. Similarly, the construction industry relies on cold-rolled steel coils to fabricate structural elements for buildings and infrastructure. Beams, columns, and other load-bearing components are commonly made from cold-rolled steel due to its superior strength and durability. Appliances and consumer goods manufacturing also make use of cold-rolled steel coils. They are frequently employed to create the outer shells of refrigerators, washing machines, and ovens, thanks to the smooth and consistent surface finish that provides an aesthetically pleasing appearance. Furthermore, the electrical industry utilizes cold-rolled steel coils in the production of electrical enclosures, transformers, and various other components. The excellent electrical conductivity and magnetic properties of cold-rolled steel make it a preferred choice for such applications. In summary, cold-rolled steel coils have diverse applications in industries including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it the favored choice for manufacturers across various sectors.

- Q: How are steel coils used in the manufacturing of body reinforcements?

- Steel coils are used in the manufacturing of body reinforcements by being shaped and molded into various components such as beams, pillars, and supports. These reinforcements provide structural strength and rigidity to the body of vehicles, ensuring safety and protection for occupants in the event of a collision.

- Q: Explain how you could make plastic sink and steel float?

- Plastics that are more dense than water will sink. For floating, you need to displace more water than you weight, so assuming steel is 10 times denser than water you will need to displace 10 times as much water weight as your steel occupies. This is easy for a wide hull ship (barge)

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Surgical Earrings

- Q: How are steel coils processed and shaped into different products?

- Different products are manufactured from steel coils through a series of manufacturing processes. The initial step is referred to as uncoiling, which entails the unwinding and straightening of the steel coil. Typically, this is achieved by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it proceeds to the leveling process. The objective of this step is to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that exert pressure and flatten the steel to achieve the desired thickness. This ensures that the steel is uniform and prepared for further processing. Following the leveling process, the steel is usually cut into smaller pieces or sheets. Machines such as shears or slitters are employed for this purpose, enabling the steel to be cut into various widths or lengths. The specific dimensions depend on the requirements of the particular product being manufactured. After the steel is cut, it can undergo additional shaping processes. One commonly used method is roll forming, in which the steel is gradually shaped into the desired profile by passing it through a series of rollers. This technique is frequently utilized in the production of roofing sheets, wall panels, or beams. Another widely used shaping process is stamping. In stamping, the steel is pressed between a die and a punch to create intricate shapes or patterns. This method is commonly employed in the automotive industry for the production of components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can involve processes like galvanizing, where a layer of zinc is applied to safeguard the steel against corrosion, or painting to provide a decorative finish. In conclusion, the process of shaping steel coils into different products encompasses a combination of cutting, shaping, and surface treatments. These processes are meticulously executed to ensure that the steel meets the required specifications and is suitable for use in various industries.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: How do steel coil manufacturers contribute to local economies?

- The local economies are positively impacted by steel coil manufacturers in various ways: 1. Job opportunities are created through the establishment and expansion of steel coil manufacturing plants. This leads to a decrease in unemployment rates and an increase in income levels, resulting in higher local spending and economic growth. 2. A network of local businesses benefits from the demand generated by steel coil manufacturers. These businesses include suppliers of raw materials, equipment, and services such as steel producers, logistics companies, packaging providers, and maintenance service providers. The presence of a steel coil manufacturer stimulates the growth and development of these local businesses, contributing to the overall economic vitality of the region. 3. The steel coil manufacturing industry acts as a catalyst for the development of secondary industries. These industries rely on steel as a primary input and include steel fabrication, construction, automotive manufacturing, and machinery production, among others. The presence of a steel coil manufacturer attracts and supports the growth of these industries, resulting in increased economic activity and job opportunities. 4. Local economies benefit from the payment of various taxes by steel coil manufacturers, including corporate income taxes, property taxes, sales taxes, and employment taxes. The significant tax revenue generated by these manufacturers can be utilized by local governments to fund public infrastructure projects, education, healthcare services, and other essential community services. 5. The economic impact of steel coil manufacturers extends beyond their direct operations. Their presence attracts other businesses and industries to the region, creating a multiplier effect. For example, steel distributors, fabricators, and processors may establish operations nearby to take advantage of the proximity to the manufacturer. This cluster of related industries further contributes to the local economy, creating a self-sustaining cycle of economic growth and development. To summarize, steel coil manufacturers contribute to local economies by creating jobs, supporting local suppliers, stimulating secondary industries, generating tax revenue, and triggering an economic multiplier effect. Their presence enhances the economic vitality of the region, leading to increased employment opportunities, income levels, and overall economic growth.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with zinc-nickel alloy. This coating provides excellent corrosion resistance and durability to the steel coils, making them suitable for various applications in industries such as automotive, construction, and manufacturing.

- Q: What is the role of steel coils in the production of conveyors?

- Steel coils play a crucial role in the production of conveyors as they are used to create the framework or structure of the conveyor belts. The coils are formed into a continuous loop, which provides strength, durability, and flexibility to the conveyor belts. Additionally, the steel coils ensure smooth movement and support heavy loads, making them essential components in conveyor manufacturing.

Send your message to us

Hot-Dip Galvanized/ aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords