Hot-Dip Galvanized/Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

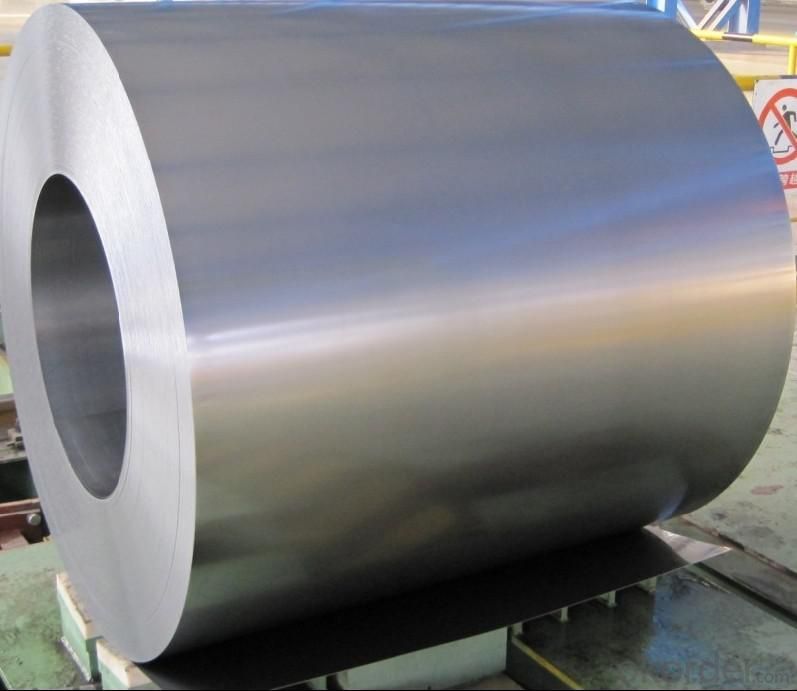

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

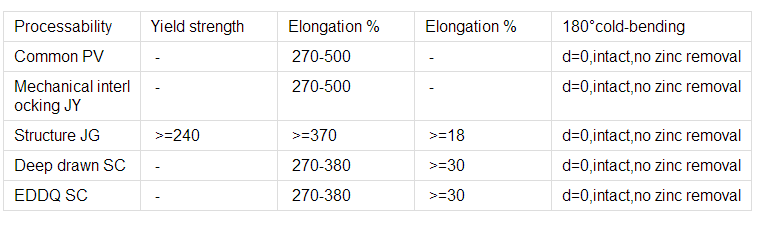

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: How are steel coils used in the manufacturing of mining equipment?

- Steel coils are used in the manufacturing of mining equipment to provide strength and durability to crucial components such as chassis, buckets, and structural frameworks. These coils are formed into various shapes and sizes, then welded or bolted together to create robust and reliable machinery capable of withstanding the harsh conditions and heavy loads encountered in mining operations.

- Q: what is magnetic steel used for and if it can be used for producing kitchenwares utenils like stainless steel basines,mugs and bowls.

- Magnetic steel rusts. That's why kitchenware is often made out of stainless. You can't turn magnetic steel into stainless, sorry. Metalurgy is a complicated subject, and is all about different alloys. It's far too involved to explain in a few paragraphs here, but no, they're not interchangeable in this case unless you want to produce kitchenware that rusts.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are several different coil packaging machine configurations used for steel coils, including horizontal coil packaging machines, vertical coil packaging machines, and orbital coil packaging machines. Horizontal coil packaging machines are typically used for smaller steel coils and provide a horizontal wrapping process. Vertical coil packaging machines are designed for larger steel coils and perform a vertical wrapping process. Orbital coil packaging machines use a rotating ring to wrap steel coils in a circular motion, providing maximum stability and protection. Each configuration offers specific advantages and is chosen based on the size and shape of the steel coils being packaged.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are inspected for coil weight accuracy after processing through the use of weighing scales or load cells. These devices measure the weight of the coil and compare it to the predetermined weight specifications. If the weight falls within the acceptable range, the coil is deemed accurate.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Great answer by JayDub. Amazon isn't exactly a great site for legitimate sword shopping. Look for legitimate retailers specializing in handmade swords.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- The manufacturing of steel furniture heavily relies on steel coils, which play a critical role. These coils, constructed from top-notch steel, act as the primary raw material for the production of various furniture items. To begin with, the framework and structure of steel furniture are created using steel coils. Manufacturers can easily cut, shape, and weld these coils into different sizes and shapes, allowing them to produce robust and enduring furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and distinctive shapes, providing both functional and aesthetic value. Additionally, steel coils are utilized to fabricate springs for furniture like sofas and chairs. The elasticity and strength of these steel coils make them ideal for crafting comfortable and supportive seating options. The coils are meticulously shaped and integrated into the furniture, ensuring that the seating surface offers the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is renowned for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture subjected to heavy use and weight load. By utilizing steel coils, the furniture can endure years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils prior to shaping them into furniture components, guaranteeing that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are a vital component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. The absence of steel coils would render the production of steel furniture impossible, compromising the quality and performance of the final products.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are essential for fabricating components like turbine blades, generator frames, and structural supports. These coils are shaped, cut, and molded into various parts, ensuring strength, durability, and stability in power generation equipment.

Send your message to us

Hot-Dip Galvanized/Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords