Hot-dip Aluzinc Steel ASTM 615 SPCCH SPCC JIS3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 65665 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

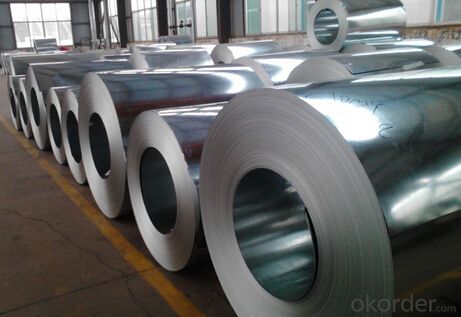

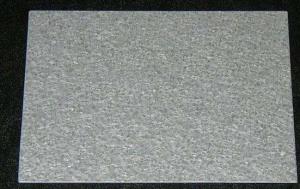

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S250GD+AZ S280GD+AZ S550GD+AZ | SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3.Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: Are steel sheets suitable for earthquake-prone regions?

- Yes, steel sheets are suitable for earthquake-prone regions. Steel is a strong and durable material that can withstand the forces generated during an earthquake. It has high tensile strength and flexibility, allowing it to absorb the seismic energy and deform without collapsing. Additionally, steel structures can be designed with proper reinforcements and connections to enhance their seismic performance. Therefore, steel sheets are a viable option for construction in earthquake-prone regions.

- Q: 16 what is the hardness of manganese steel plates?

- 16 hardness of manganese steel plate is 45 -50HRC.

- Q: What is the typical corrosion resistance of a steel sheet?

- The typical corrosion resistance of a steel sheet can vary depending on factors such as the specific type of steel, the presence of protective coatings, and the environment in which it is exposed. However, steel sheets are generally known for their moderate to high corrosion resistance due to the presence of alloying elements such as chromium and nickel.

- Q: Can steel sheets be used for storage tanks?

- Yes, steel sheets can be used for storage tanks. Steel is a strong, durable, and corrosion-resistant material, making it suitable for containing various materials and liquids in storage tanks.

- Q: How are steel sheets protected from rust and corrosion?

- Steel sheets are protected from rust and corrosion through a process called galvanization, which involves coating the sheets with a layer of zinc. This zinc layer acts as a barrier, preventing moisture and oxygen from reaching the steel surface and causing rust.

- Q: What are the different finishes available for steel sheets?

- Some of the different finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: Are the steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding due to their durability, strength, and versatility in design. Steel sheets can be fabricated into various shapes and sizes, offering flexibility for architectural purposes. Additionally, they provide excellent weather resistance and require minimal maintenance, making them an ideal choice for cladding applications.

- Q: How long do steel sheets last?

- The lifespan of steel sheets can exceed that of other materials, lasting for many years. Several factors influence the longevity of steel sheets, including the quality of the steel, the conditions it encounters, and the level of maintenance it receives. Typically, steel sheets of superior quality that are correctly installed and well-maintained can endure for several decades, or even longer. Nevertheless, if steel sheets are exposed to severe environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may diminish. To prolong the lifespan of steel sheets and guarantee their durability, regular inspections, cleaning, and maintenance are essential.

- Q: How do steel sheets compare to fiberglass sheets?

- Steel sheets and fiberglass sheets have various differences in terms of strength, weight, and durability. Steel sheets are generally stronger and more rigid than fiberglass sheets, making them suitable for applications where high strength is required. They also have better resistance to impact and fire, making them safer in certain environments. However, steel sheets are heavier and more prone to corrosion compared to fiberglass sheets. Fiberglass sheets are lighter, have better resistance to chemicals and weathering, and are non-conductive, making them ideal for electrical applications. Additionally, fiberglass sheets are easier to handle and install due to their flexibility. Overall, the choice between steel and fiberglass sheets depends on the specific application requirements and priorities.

- Q: How do steel sheets handle thermal conductivity?

- Steel sheets have high thermal conductivity, which means they can efficiently transfer heat. This property allows steel sheets to quickly and evenly distribute heat across their surface, making them suitable for various applications such as heat transfer systems, cookware, and building materials.

Send your message to us

Hot-dip Aluzinc Steel ASTM 615 SPCCH SPCC JIS3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 65665 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords