Fireclay Brick for Hot-Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

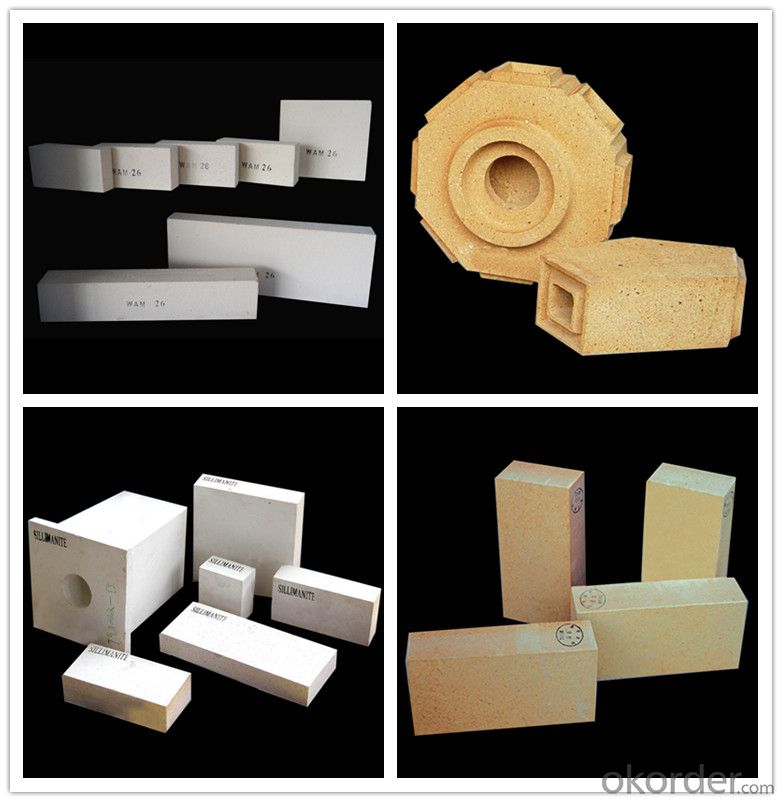

High alumina fireclay Brick

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

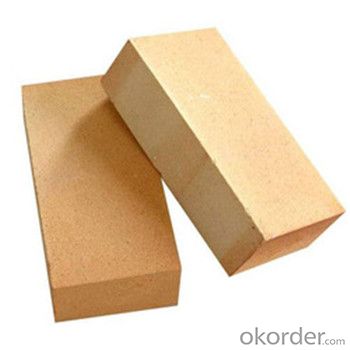

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

FAQ:

Q1: How about your factory’s annual production capacity?

A1:CMAX annual production is about 310,000Tons.

Q2: How many production lines of your factory?

A2:CMAX has 26 production lines, including eight silicon bricks lines, and each one of mullite brick, high alumina brick, insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: CMAX covers almost 200,000 Square meters, including plant area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:CMAX main products are: refractory for hot blast stove, refractory for coke oven, refractory for glass kiln, refractory for carbon calcining furnace, refractory for acid pickling line, refractory for cement kiln, refractory for blast furnace, refractory for nonferrous metal furnace, and basic refractory raw materials.

Product Picture

Produce Processing

Crushing

In this stage massive raw materials which have been stored, are ground and classified into proper sizes, making them easier to shape.

Mixing

The prescribed size of ground raw material is weighed and mixed into a designated amount of water and forming agent.

Shaping

The mixture is then poured into a mold to form shapes, and the pressure is high.

Drying

In this stage water is removed from the shaped bricks. This helps preventing the bricks from deforming or cracking which may result due to the rapid evaporation

Firing

This is the most crucial process in refractory manufacturing. The modeled bricks are fired at high temperature to complete their thermochemical reaction so that they do not deform.

Inspection

The bricks' physical and chemical properties are inspected very carefully by rigid quality management procedures.

Packing shipment

We guarantee efficient delivery every time.

Packing

We also supply (Click on following picture if interested):

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- Thermal shock stability is much better than clay brick.

- Q: Can refractory bricks be used when it cracks for 1cm

- 3, If the crack is caused by burning or drying, then it can't be used. While if the carck is caused by refractory brick molding, it still can be used. 4, the crack is caused by refractory bricks raw materials.

- Q: is it good to use firebricks to preserve the heat of rto furnace? Is there any other good ideas?

- Operating noise is very low, having a very strong chemical stability: The thermal conductivity is lower than 0 at normal temperature, it not only reduced the cost of the project of RTO furnace, but keeps the indoor heat dissipation heat better and reduce noise pollution. the temperature of RTO furnace surface is low after using the ceramic fiber lining to keep the heat, thereby reducing the addition of auxiliary fuel : ceramic fiber has a good thermal shock resistance: The dosage form of HLGX-589 and HLGX-312 ceramic fiber material is shown in figure RTO furnace thermal insulation material. C, good thermal shock resistance, without reserving expansion joints, ensure the lining intact, not easy to be affected by the harsh combustion atmosphere inside the RTO furnace, can deal with the temperature changes caused by periodic replacement of RTO furnace inlet. The furnace is new energy-saving furnace developped recent 30years that used for eliminating harmful exhaust gas caused by steel or paint spraying. it has long service life, high chemical stability, no heat preservation precedent for refractory bricks; B, good heat insulation effect.

- Q: What are 85 bricks, 95 bricks and standard bricks? What are the specifications?

- Chinese in the spring and Autumn period has created a square and brick, Qin and Han Dynasties brick technology and production scale, quality and variety have significant development, known as "Qin Zhuanhan tile".

- Q: What is the sintering of non clay bricks?

- Many kinds of brick, according to the raw materials used for clay brick, shale, coal gangue brick, fly ash brick, lime sand bricks and slag brick; according to the production process can be divided into sintered brick and non sintered brick, which can be divided into non sintered brick brick, autoclaved bricks and autoclaved brick etc.; according to whether the holes can be divided into ordinary bricks, porous brick, hollow brick.

- Q: Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q: The shape and size of general used refractory brick

- According to the national standard, the outline dimension of mechanism red brick is: length is 240mm, width is 115mm and thickness is 53mm. That is: 240mm * 115mm * 53mm. The shape and size of the ordinary refractory bricks are: Length is 230mm, width is 114mm and thickness is 65mm, that is: 230mm * 114mm * 65mm. The shape and size of special refractory bricks are: 345mm*328mm*97mm.

- Q: Do slag bricks have clay bricks strong enough?

- Red bricks are the most durable in construction, and the cost of red brick is also relatively high in cost.

- Q: The service life of the refractory brick of the intermediate frequency electric furnace, how long is the replacement period.

- There is no standard. As long as the induction coil can be fixed and furnace lining can be built, the service life will be different. Replace it if it's broken, and there is no problem to take it apart. Buy a backup. And the textures of refractory brick are not the same in different places.

- Q: does the electric kiln burner need to be sealed?

- seal when open the kiln, and observe the temperature, when the temperature reaches a point, you can move the firebrick away, and continue observing the temperature to decide whether to seal it or not, but do not seal it completely, repeat the procudure until reach the sinter point or skill requirement.

Send your message to us

Fireclay Brick for Hot-Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords