HLS90 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

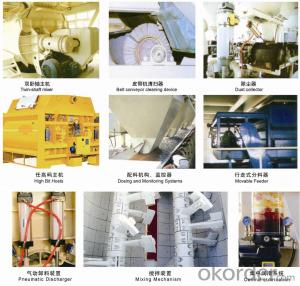

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS90 | |

Production capacity (m3/h) | 90 | |

Concrete mixer | Model | JS1500 |

Power (kW) | 2x30 | |

Output capacity (m3) | 1.5 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 12 |

Belt conveyor deliverability (t/h) | 450 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 3500±2% |

Cement (kg) | 800±1% | |

Fly ash (kg) | 200±1% | |

Water (kg) | 300±1% | |

Admixture (kg) | 30±1% | |

Discharging height (m) | 3.8 | |

- Q: Is your baby okay with hornets, bees, heavy machinery and phosphorous?

- Well, since I live in New Orleans, I do dress him in Hornets attire, but he does not like the last two.

- Q: please hurry school project due TODAY

- Big giant coal burning factories with smoke stacks.

- Q: Human capital refers to:Answerthe skills and knowledge that enable a worker to be productive.machinery used by labor in production.the accumulated financial wealth of households.physical capital owned by households rather than businesses.

- the skills and knowledge that enable a worker to be productive.

- Q: A few years back I remembered seeing something on an ad on tv describing like a box you put over loud machinery like an air compressor so it will become quiter and even silence it. I don't know the name but from what I remember it was a white looking box very large.

- You can build a box using 1x or 2x lumber and plywood, depending on how big you need it. Then line the box with either egg crate foam or styrofoam. Both act as noise supressors. Be sure to allow room for ventilation if needed.

- Q: Examples being, Caterpillar bulldozers, skid steer loaders, front end loaders, steamrollers, etc.If so, what's the process of getting a license to do so?

- NO, you do not there are schools though that offer training as well as companies that provide on the job training. But there are not any licenses even for on the job trucks where you do not leave the job site.}{

- Q: POLL: would you rather live in a world with TOO MUCH technology, or live a primitive life, without machinery?

- Live a primitive life- it's much easier to prevent the crap we create on this earth before it happens than clean it up after we've dumped it everywhere...

- Q: I just recently aquired some freshly cut maple and was interested in possibly turning into a snare drum. The only problem is that i cant figure out how. Ive searched on the internet and have come up relatively short on how to actually construct the shells themeselves. If anyone could point me in the right direction or give me some helpful hints it would be greatly appreciated.

- do nothing

- Q: I am searching for a career path that would involve my interests which are dirt biks, atv's and working on machinery. I would like to make at least $50,000 a year.

- Good luck, there isnt much unless you get signed to a race ream or work somewhere big.

- Q: Are motorcycles, farm machinery, bicycles allowed on Ohio's I-71 and I-70?

- Motorcycles yes. no farm machinery or bicycles.

- Q: Who can introduce the famous domestic machinery enterprises?!

- 3 China National Machinery Industry Corp [cnmic] was founded in January 1997, formerly known as China machinery equipment (Group) company, is a large state-owned enterprise established by the State Council, the state owned assets supervision and Administration Commission of the State Council Membership Management directly.

Send your message to us

HLS90 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords