HLS240 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

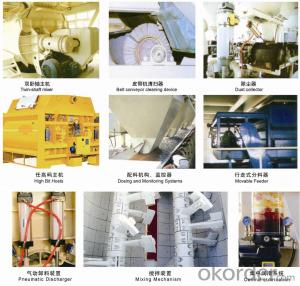

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

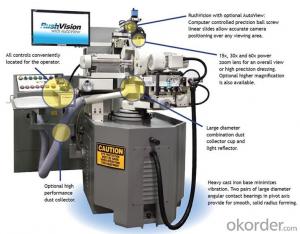

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS240 | |

Production capacity (m3/h) | 240 | |

Concrete mixer | Model | JS4000 |

Power (kW) | 2×75 | |

Output capacity (m3) | 4 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | underground bin |

Belt conveyor deliverability (t/h) | 1000 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(4000±2%) |

Cement (kg) | 2000±1% | |

Fly ash (kg) | 800±1% | |

Water (kg) | 800±1% | |

Admixture (kg) | 100±1% | |

Discharging height (m) | 3.8 | |

- Q: again?510 511 145

- not about books or authors ? but 5 and 1/2 hours

- Q: What is a mechanical mouse?

- At present, the mouse on the market is divided into two major categories according to principle: one is mechanical mouse, and the other is photoelectric mouse. And now the wireless mouse. Mechanical mouse identification is very simple, the mouse flip over, if there is a small ball, it is a mechanical mouse.

- Q: I always wondered if nerves sent signals to our muscles, if someone lost a leg or an arm, is it theoretically possible to attach someone's nerves to machinery and control it like a limb?

- yes i have heard some work is being done with that

- Q: I am not talking about homemade reloading. I'm talking about pooling up some money with some of my friends to buy commercial bullet/ammunition making machinery equipment, to manufacture our own ammunition from scratch, from the basic materials such as powder, lead, brass, and copper to the finished product = 1 fully assembled round of ammo.Due to the ammo shortage I see now, I see a great investment and commercial opportunity. Lead, copper, brass, and powder can be found in vast quantities, but ammo is in a shortage. But if I have the machines to melt, process, and combine these materials, I no longer have an ammo shortage. Where can I buy commercial ammo making machinery?

- In reality you WON'T save money by reloading 5.56,7.62x39 or 54R,there is just too much cheap stuff available and you will take too long recouping your costs when accounting for the press,dies,accessory equipment plus your consumables-and THEN add in your time. Reloading works well to gain accuracy or load for expensive or less supported cartridges-I reload for a 300 WSM instead of spending $40+ a box,so reloading for the other rifles is a bonus save/accuracy gain. If you had a WSM,Weatherby proprietary,RUM,RSAUM, boutique cartridges, 375 HH or larger;or things like a hot 6.5 x 55 Swede load,7mm Mauser,etc it would return your investment quickly. Your 300 Win Mag might get some accuracy gains and of course you can load specific bullets,but when you add a pistol cartridge you start needing a turret press instead of a single stage-almost doubles the press cost. Not going to dissuade you from reloading for what you can gain,but economically,it takes a while to see a benefit-and in the Russian loads you are dealing with questionable accuracy gains anyway. Best thing is to see what the Lee,RCBS,Redding,Hornady kits have in common-press,scale,hand primer, Lube Pad,etc-add to that a decent dial caliper,case trimmer of some type(Lee and RCBS take two TOTALLY different approaches),tumbler,and a bullet puller maybe.

- Q: I want to know if a 16 year old in North Dakota can operate 1. Buffer (buffs the floor)2. Scrubber (pushing a machine that washes the ground and dries it)

- The thing is that cleaning companies usually are and should be bonded and insured, and I dont know if they will do that below age 18

- Q: Does Santa Claus use any modern machinery in his workshop?

- Absolutely NOT!! A world of magic and elven craftsmanship will out-produce any known modern manufacturer. Santa ROCKS.

- Q: Classification of machinery and equipment

- The general petrochemical machinery, oil drilling machinery, oil machinery, chemical machinery, pump, blower, valve, gas compressor, refrigeration and air conditioning machinery, paper machinery, printing machinery, plastic processing machinery, pharmaceutical machinery etc.. Electrical machinery: power generation machinery, transformers, motors, high and low voltage switches, wires and cables, batteries, welding machines, household appliances, etc.. Machine tools: metal cutting machine tools, forging machinery, casting machinery, woodworking machinery, etc..

- Q: Hi,My company produces industrial machinery, which for the purposes of this can best be described as a range of different size metal boxes with internal fittings. Currently, we make these from aluminium extrusion and steel infill panels. I'm looking to redesign.Does anyone have suggestions for alternative component systems which provide reasonably strong structures, while being assembled without welding and do not require painting? I've looked at aluminium composite panels and GRP.ThanksS

- Have you considered manufacturing the enclosures from galvanized sheet metal, which can be fabricated into weather resistant enclosures using a metal brake and pop rivets?

- Q: For example:- Have you repaired the machinery?- Yes, I have repaired (it / them).

- I would always use it. The word machinery is singular.

- Q: I want to buy some used machinery worth $20,000.00 from Canada to USA. does anybody know if I can just put it in Uhaul truck bring it back or do I have to pay duties how much

- I believe you have to get the machinery past customs and you have to get import paperwork done.

Send your message to us

HLS240 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords