HLS300 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

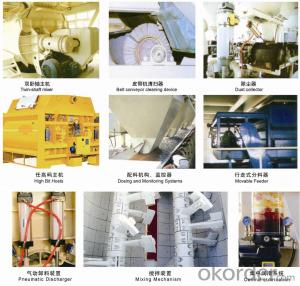

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS300 | |

Production capacity (m3/h) | 300 | |

Concrete mixer | Model | JS5000 |

Power (kW) | 2×75 | |

Output capacity (m3) | 5 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | underground bin |

Belt conveyor deliverability (t/h) | 1000 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(5000±2%) |

Cement (kg) | 3000±1% | |

Fly ash (kg) | 1000±1% | |

Water (kg) | 1200±1% | |

Admixture (kg) | 100±1% | |

Discharging height (m) | 3.8 | |

- Q: how much do they cost to replace a broken one?thanks..

- You can get an exact replacement window from cat but it will be expensive ($300 or more) depending on the size of the window. You can call the local cat house and they will be happy to give you a price, you will need the model and serial number for the parts man to look it up. If it is just broken glass and the gasket and frame are OK you can go to a local glass company and get a new window cut which should save you some money.

- Q: have trouble doing anything as i injured my right hand an i'm right handed and live alone.

- If you were injured on the job the state workers compensation commision has rules and regulations that govern disability ratings and monetary amounts of compensation for each disability... many states (texas is the worst) laws are designed to protect the insurance companies and to screw the injured worker... you should definitely consult an attorney.

- Q: Engineering machinery as the main means of project construction industry in recent years (including construction machinery, road construction machinery) and demand has increased rapidly, which stimulates the use of the manufacturing, engineering machinery, maintenance industry often demand. At the same time, the high-tech construction machinery, maintenance equipment maintenance maintenance numerous, complex process, high technical requirements and related mechanical engineering research and development, manufacturing, sales, use, maintenance and other personnel, enterprises generally reflect the lack of.

- The use of engineering machinery and maintenance of professional learning mechanical drawing, engineering mechanics, electrical and electronic technology, mechanical design, hydraulic and pneumatic technology, principle and mechanical parts, engineering machinery, mechanical structure of the theory of CAD/CAM technology, automatic control technology, industrial enterprise management. The use of engineering machinery and maintenance of professional training to master the engineering mechanical structure, control and design of the basic theory and professional knowledge, engaged in engineering machinery installation, commissioning, operation and maintenance and technical management of advanced technology applied talents.

- Q: Certain medications saygt;gt;gt;Do not drive or operate machinerylt;lt;lt;lt;What kind of machinery are they talking about?

- Anything that could hurt you or others if your reaction time is slowed, or your judgement is impaired - bulldozers, table saws, drill press, crane, threshers, etc. etc. etc. Easier to say machinery.

- Q: Write 3 machines you hate the most and give reasons why?!!!thanks!(not cars,others)

- 1.the vacuum cleaner or whatever it's name is. it's noisy. 2.the alarm clock. it's noisy. 3.the roller coaster. i'm scared of it and i always feel like a crybaby when everyone rides and they tell me to join and i have to remind them that i'm afraid of heights.

- Q: electrical machineries

- For large or largish generators steam turbines gas turbines wind turbines water turbines diesel engines

- Q: Would it be considerd against ethics to use city owned equipment for the athletic club dept, which is a county owned school? This equipment is being used after hours and weekends too for athletic club use.

- If the city allowed the use, there is no ethical issue.

- Q: A CPA told me that (around) 7% for the first year is normal for business machinery depreciation. My question is... if you bought the machine during the year, can you only depreciate it based upon the ratio of days you owned it to the year, or can you depreciate it as if you owned it the whole year?For instance, on March 1st I bought a machine for $100,000. Can I depreciate it for the MACRS yearly rate, or do I need to treat the depreciation as a partial year portion of the possible depreciation rate? (lt; approx 7%)?

- partial year or you can use section 179 or section 168 to expense greater than normal amounts.

- Q: Engineering engines use those engines as power!

- A diesel engine used on construction machinery.. What brands do you have?.. For example: working with deutz. Steyr。。 Other summer jobs. Liugong. Temporary workers. What engine do you use?

- Q: i need info on the following machinery that were used in the WWIpics and videos are accepted as well bolt-action rifle machine guns artillery/ shells flamethrowers thanx !!!! :D

- Hiram Maxim invented the first true machine gun and offered it to his native country, the US. The War Department Procurement Office said, No, them boys will shoot too many bullets! Who'll pay for them? and turned it down. Actually, the Procurement Officers had all been offered lucrative jobs at Colt's Manufacturing, just like now. Hiram took his gun to England, who did buy a license to make the gun under the Vickers name, but it was the Germans who really saw the advantages of Maxim's gun. They learned to lay in crossing fields of fire so that each gun protected the guns on either side of it. This was a murderous advantage to defending positions.

Send your message to us

HLS300 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords