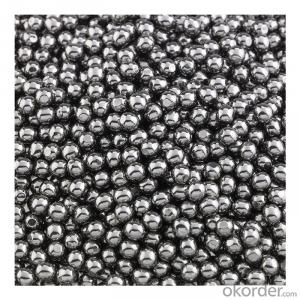

Hign Quality and useful Casting Roll Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT

- Min Order Qty:

- 8 unit

- Supply Capability:

- 4 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The main working parts and tools that produce continuous plastic deformation of the metal on the rolling mill. The roll is mainly composed of three parts: roll body, roll neck and shaft head. The roll body is the middle part of the roll that actually participates in rolling the metal. It has a smooth cylindrical or grooved surface. The roll neck is installed in the bearing, and the rolling force is transmitted to the stand through the bearing seat and the pressing device. The shaft end of the transmission end is connected with the gear seat through the connecting shaft, and transmits the rotating torque of the motor to the roller. The rolls can be arranged in the form of two-roll, three-roll, four-roll or multi-roll in the mill stand.The roll neck is installed in the bearing, and the rolling force is transmitted to the stand through the bearing seat and the pressing device. The shaft end of the transmission end is connected with the gear seat through the connecting shaft, and transmits the rotating torque of the motor to the roller. The rolls can be arranged in the form of two-roll, three-roll, four-roll or multi-roll in the mill stand.

- Q: What are the different types of steel sheets and their applications?

- There are several types of steel sheets, including hot rolled, cold rolled, galvanized, and stainless steel sheets. Hot rolled sheets are used in structural and construction applications due to their strength and durability. Cold rolled sheets are commonly used in automotive and appliance industries for their smooth surface and precise dimensions. Galvanized sheets are coated with zinc to prevent corrosion, making them suitable for outdoor applications such as roofing and fencing. Stainless steel sheets are resistant to corrosion and heat, making them ideal for food processing, chemical, and medical industries.

- Q: How is steel used in the manufacturing of appliances?

- Steel is commonly used in the manufacturing of appliances due to its strength and durability. It is used to construct the outer casings and frames of appliances, providing structural support and protection. Additionally, steel is used for internal components such as heating elements, coils, and grills, where its heat resistance and conductivity are beneficial. Overall, steel plays a crucial role in ensuring the longevity and performance of appliances.

- Q: How is steel used in the manufacturing of consumer goods?

- Steel is commonly used in the manufacturing of consumer goods due to its strength, durability, and versatility. It is used to create various components and structures in products such as appliances, automobiles, furniture, tools, and electronics. Steel is essential for providing stability and support, ensuring the longevity and safety of consumer goods.

- Q: How do steel products contribute to the construction of theme-based botanical gardens?

- Steel products contribute to the construction of theme-based botanical gardens in several ways. Firstly, steel is a versatile material that can be used to create structural frameworks, such as support beams and columns, for the garden's buildings and structures. These steel structures provide stability and strength, ensuring the safety of visitors and the longevity of the garden. Additionally, steel is commonly used for constructing bridges and walkways within botanical gardens, allowing visitors to navigate through different areas and enjoy the beauty of the garden from various perspectives. Steel's durability and resistance to corrosion make it ideal for outdoor installations that are exposed to the elements. Moreover, steel is often utilized for creating decorative elements and sculptures within botanical gardens. Its malleability enables intricate designs to be formed, adding aesthetic value and enhancing the overall theme of the garden. Overall, steel products contribute significantly to the construction of theme-based botanical gardens by providing structural integrity, functional walkways, and artistic elements, ultimately enhancing the visitor experience and ensuring the garden's long-term sustainability.

- Q: What are the common types of steel products used in the wastewater treatment industry?

- Some common types of steel products used in the wastewater treatment industry include stainless steel tanks, pipes, and fittings. These materials are chosen for their corrosion resistance and durability, ensuring they can withstand the harsh and corrosive environment of wastewater treatment plants. Additionally, steel products are often used in the construction of various structures such as clarifiers, sedimentation tanks, and pump stations within the wastewater treatment industry.

- Q: How is steel used in the aerospace industry?

- Steel is used in the aerospace industry for various applications such as structural components, landing gears, engine parts, and aircraft frames. It provides strength, durability, and resistance to high temperatures, making it suitable for withstanding the rigorous demands of aerospace operations.

- Q: How is steel used in the manufacturing of storage tanks?

- Steel is commonly used in the manufacturing of storage tanks due to its durability, strength, and resistance to corrosion. It provides a sturdy structure that can withstand high pressures and extreme weather conditions. Steel tanks can be fabricated in various sizes and shapes to accommodate different storage needs, making them versatile for storing various substances such as water, oil, chemicals, and gases.

- Q: What are the advantages of using steel in shipbuilding?

- There are several advantages to using steel in shipbuilding. Firstly, steel is a strong and durable material, making it ideal for constructing large and heavy vessels that can withstand harsh ocean conditions. Secondly, steel has excellent corrosion resistance, which helps to prolong the lifespan of the ship and reduces maintenance costs. Additionally, steel is readily available and cost-effective, making it a practical choice for shipbuilding. Finally, steel is highly versatile and can be easily shaped and welded, allowing for the construction of complex ship designs and facilitating efficient production processes.

- Q: How are steel products used in the construction of power plants?

- Steel products are extensively used in the construction of power plants due to their strength, durability, and resistance to extreme conditions. They are employed in various applications such as the fabrication of structural frameworks, support beams, and platforms, as well as for the construction of pressure vessels, pipelines, and storage tanks. Steel is also used in the manufacturing of turbines, generators, and other equipment essential for power generation. Overall, steel products play a crucial role in ensuring the stability, safety, and efficiency of power plants.

- Q: What are the different types of steel flooring and decking available?

- There are several different types of steel flooring and decking available, including open steel grating, steel plate flooring, and composite steel decking. Open steel grating consists of steel bars or gratings that are spaced apart to allow for the passage of light, air, and water. Steel plate flooring is made from solid steel plates that are typically welded or bolted together to create a strong and durable surface. Composite steel decking incorporates a combination of steel and concrete to provide a lightweight and efficient flooring system. Each type of steel flooring and decking has its own unique advantages and applications.

Send your message to us

Hign Quality and useful Casting Roll Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT

- Min Order Qty:

- 8 unit

- Supply Capability:

- 4 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords