Hight Quality Galvanized Steel (0.12-1.2mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Surface Treatment:Galvanized

Certification:ISO, SGS

Technique:Hot Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Q235B

Size:0.12-1.2mm

Export Markets:Global

Additional Info.

Packing:Standard

Standard:CE

Origin:China

Production Capacity:50000psc

Product Description

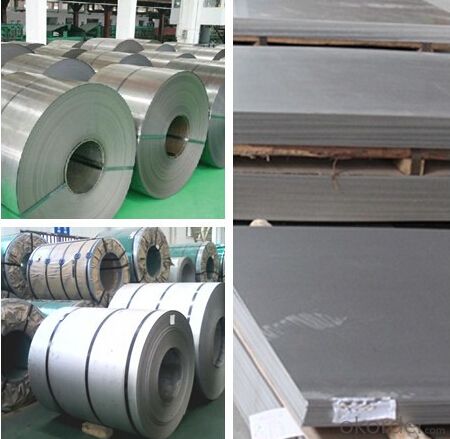

NAME: Color Coated Galvanized Steel Coil/PPGI

SIZE:

Thickness: 0.12-1.2mm

Width: 600mm-1250mm (STD914mm,1000mm, 1200mm, 1219mm, 1250mm)

Thickness tolerance: +/-0.02mm or control in 0.1 according to customer's requirement

Width tolerance: +/-2mm

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: Galvanized steel coils\ Galvalume steel, such as SGCC, CGCC, DX51D+Z, Q195,etc

Base metal: Hot galvanized steel or PrePainted Galvanized aLuminium steel or HBR>85

Techinque: Cold rolled, hot-dipped galvanizing, color coated

Quality: CQ DQ prime

| Commodity | Color Coated Galvanized Steel Coil/PPGI |

| Techinical Standard | ASTM, JIS, GB, AISI, DIN, BS |

| Grade | Q195 Q235 Q235B SGCC DC51D DC52D DC51D+Z |

| Thickness | 0.12-1.2mm |

| Width | 600-1250mm |

| Coil weight | 3-6tons |

| Type of coating | Galvanized |

| Zinc coating | 30-120G/M2 |

| Coil ID | 508mm or 610mm |

| MOQ | 25 MT |

| Supply capacity | 300000MT/per year |

| Package | standard sea worthy package |

| Origin | Shandong Province.China |

| Trademark | |

| Application | Industrial panels, roofing and siding for painting |

| Price terms | FOB, CFR, CIF |

| Payment terms | 30%T/T in advance+70% T/T or irrevocable 100% L/C at sight |

| delivery time | 10-20 days after recepit of 30% T/T |

| Remarks | Insurance is all risks |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: What metals contain steel? It can be anything except soft iron or steel.

- tricky situation. look from google. it may help!

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: I have to explain some functions of stainless steel but after days of searching I cant find an answer. Thankyou in advance for your help :)

- nicely worth little or no so a great way as i'm in contact. It has an somewhat destructive co useful of heat, is confusing to lubricate to maintain the meals from sticking and could strengthen a warm spot somewhat. My decision is a good high quality forged iron, it extremely is heavy yet conducts warmth nicely and spreads it flippantly. Stainless with copper bottoms is marginal for boiling water whether it does sparkling somewhat. There are countless alloys on the industry that are usable as cook dinner ware. Aluminum is worse than stainless. Of the organic metals, copper is the suited conductor of heat, forged iron is my decision, spun metallic does artwork. desire this helps. never wash forged iron cookware with cleansing soap and water.

- Q: How are steel coils used in the production of industrial machinery?

- Steel coils are used in the production of industrial machinery as they can be processed and shaped into various components such as structural supports, frames, and gears. The coils are often cut, bent, and welded to create the necessary parts that form the foundation of the machinery, ensuring strength, durability, and efficient operation.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils find extensive application in the production of electronic devices, serving various purposes. One prominent utilization lies in the manufacturing of transformers and inductors, which constitute essential components in numerous electronic devices. These components comprise a coil of wire wound around a core, with steel coils often serving as the core material due to their magnetic properties. The magnetic properties of steel contribute to amplifying the magnetic fields generated by the coils, facilitating effective energy transfer and voltage regulation. Steel's magnetic attributes, such as high permeability and low hysteresis loss, make it an ideal material for such applications. Furthermore, steel coils are also integral to the production of printed circuit boards (PCBs). PCBs, acting as the backbone of most electronic devices, consist of a flat, non-conductive board like fiberglass, adorned with a thin layer of copper traces etched onto it. These copper traces establish the electrical connections between different components on the board. Steel coils play a role in the PCB fabrication process, specifically in the creation of stencils. These stencils are employed to apply solder paste onto the board before component placement. Laser-cut steel coils give rise to accurate and consistent stencil patterns, ensuring precise solder paste application. To summarize, steel coils fulfill a crucial function in the production of electronic devices. They are employed in the manufacturing of transformers and inductors, enhancing energy transfer and voltage regulation through their magnetic properties. Additionally, steel coils contribute to the fabrication of PCBs by creating stencils for solder paste application. Overall, the use of steel coils guarantees the efficient and dependable operation of electronic devices.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: How do steel coils affect the quality of finished products?

- The quality of finished products in various industries can be greatly influenced by steel coils. Dimensional accuracy and consistency are key factors that determine the impact of steel coils on product quality. When steel coils are not properly manufactured or have irregular dimensions, it can cause issues in the production process and result in finished products that do not meet the desired specifications. Moreover, the final appearance and performance of finished products are heavily dependent on the surface quality of steel coils. Defects such as scratches, rust, or unevenness in the coils can have a negative impact on the aesthetic appeal of the products, making them less desirable to customers. Additionally, these defects can compromise the functionality and durability of the finished products, potentially leading to failures or a reduced lifespan. The mechanical properties of steel coils also play a crucial role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. This is especially important in industries like automotive or construction, where strength and reliability are of utmost importance. The use of steel coils with incorrect mechanical properties can lead to safety hazards or structural failures. Furthermore, the chemical composition of steel coils can have a significant impact on the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other important properties. This, in turn, can affect the longevity and functionality of the final products. In conclusion, steel coils have a significant influence on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is essential to ensure that steel coils used in manufacturing processes meet the required standards to achieve high-quality finished products.

- Q: How are steel coils inspected for hardness using hardness testers?

- Steel coils are inspected for hardness using hardness testers by applying a specific amount of force onto the surface of the coil and measuring the depth or indentation left by the indenter. This indentation is then compared to a hardness scale to determine the hardness of the steel.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

Send your message to us

Hight Quality Galvanized Steel (0.12-1.2mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords