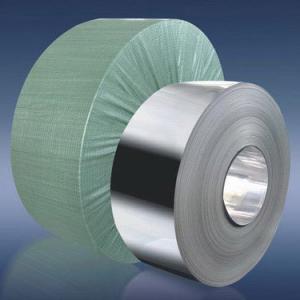

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness<0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: What are the applications of steel angles?

- Steel angles have a wide range of applications in various industries. They are commonly used in construction for structural framing, providing support and stability to buildings. Steel angles are also used in the manufacturing of machinery, equipment, and vehicles, where their strength and durability are crucial. Additionally, they find application in the fabrication of infrastructure such as bridges, walkways, and platforms. The versatility of steel angles makes them valuable in many other applications, including shelving, fencing, and reinforcing concrete structures.

- Q: How do steel products contribute to the construction of dams and reservoirs?

- Steel products contribute to the construction of dams and reservoirs in various ways. Firstly, steel is used to reinforce the concrete structures, making them stronger and more durable. Steel bars, known as rebar, are embedded within the concrete to provide tensile strength and prevent cracking. Additionally, steel sheets are often used as formwork to shape and support the concrete during its curing process. Moreover, steel is utilized in the manufacturing of gates, turbines, and other mechanical components required for the operation of dams and reservoirs. Its high strength-to-weight ratio makes it ideal for constructing these large-scale infrastructure projects, ensuring their stability and longevity.

- Q: What are the different types of steel rods and their applications?

- There are several types of steel rods commonly used in construction and manufacturing. Some common types include mild steel rods, stainless steel rods, carbon steel rods, and alloy steel rods. Mild steel rods are widely used due to their affordability and versatility. They are commonly used in general construction, reinforcement of concrete structures, and fabrication of fences and gates. Stainless steel rods offer excellent corrosion resistance and are used in applications where hygiene and aesthetic appeal are important, such as in food processing, pharmaceuticals, and marine environments. Carbon steel rods are known for their high strength and durability. They are commonly used in heavy-duty construction projects, such as bridges, high-rise buildings, and infrastructure. Alloy steel rods are made from a combination of different metals, offering specific properties such as increased strength, hardness, and resistance to wear and tear. They are often used in applications that require high performance, such as automotive parts, machinery, and tooling. Overall, the choice of steel rod depends on the specific requirements of the application, considering factors such as strength, corrosion resistance, cost, and environmental conditions.

- Q: What are the different types of steel profiles and their uses?

- There are several different types of steel profiles, including I-beams, H-beams, angle iron, channel, and flat bars. I-beams are commonly used in construction and engineering projects to provide structural support. H-beams are similar to I-beams but have wider flanges, making them better suited for heavier loads. Angle iron is often used for framing and support structures, while channel steel is commonly used in the construction of walls, roofs, and floors. Flat bars are versatile and can be used for various applications, such as braces, supports, and decorative purposes.

- Q: How do steel products contribute to the mining and excavation industry?

- Steel products play a vital role in the mining and excavation industry by providing essential equipment and infrastructure. Steel is used to manufacture heavy machinery, such as excavators, bulldozers, and drilling rigs, which are crucial for extracting minerals and ores from the earth. Additionally, steel is used in the construction of mine shafts, tunnels, and support structures, ensuring the safety and stability of mining operations. Its durability and strength make steel products indispensable in this industry, enabling efficient and productive mining and excavation activities.

- Q: How is steel wire galvanized for wire rope applications?

- Steel wire is galvanized for wire rope applications through a process called hot-dip galvanization. In this process, the steel wire is thoroughly cleaned to remove any impurities and then dipped into a bath of molten zinc at a temperature of around 450 degrees Celsius. The zinc coating bonds to the surface of the steel wire, creating a protective layer that helps prevent corrosion and extends the lifespan of the wire rope.

- Q: What are the common types of steel products used in the mining industry?

- The common types of steel products used in the mining industry include steel pipes, steel plates, steel bars, and steel structures. These products are used for various applications such as transporting materials, supporting mining equipment, and constructing infrastructure in mining operations.

- Q: How are steel pipes used in the transportation of natural gas?

- Steel pipes are commonly used in the transportation of natural gas due to their strength, durability, and resistance to corrosion. These pipes are used to create a network of pipelines that transport natural gas from production wells to distribution centers and ultimately to homes, businesses, and industries. The steel pipes are designed to withstand high pressure and can transport large volumes of natural gas over long distances efficiently and safely.

- Q: What are the different grades and specifications of steel products?

- There are various grades and specifications of steel products, each designed for specific applications and requirements. Some common grades include carbon steel, stainless steel, and alloy steel. Carbon steel grades range from low carbon (mild) steel to high carbon steel, with varying levels of strength, durability, and ductility. Stainless steel grades are classified based on their corrosion resistance and can range from austenitic to ferritic or martensitic. Alloy steel grades contain additional elements such as manganese, silicon, nickel, or chromium to enhance specific properties like hardness, toughness, or heat resistance. Additionally, steel products have different specifications such as size, shape, finish, and tolerance levels, which are determined by industry standards and customer needs.

- Q: What are the uses of steel in the construction of hotels and resorts?

- Steel is widely used in the construction of hotels and resorts due to its exceptional strength and durability. It serves various purposes such as providing structural support, forming the framework of the building, and reinforcing concrete structures. Steel beams and columns are used to create large open spaces, allowing for flexible and efficient floor plans. Additionally, steel is utilized in the construction of staircases, elevator shafts, and roofing systems. Its fire-resistant properties and ability to withstand extreme weather conditions make it an ideal choice for ensuring the safety and longevity of hotels and resorts.

Send your message to us

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords