High Voltage Frequency Drive 6KV 1120KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product:

AC Drives/Variable speed drive/ Variable frequency inverter/Frequency inverter/converter (AC motor drives), Soft starter.

0.4~630KW, 220~690V.

Keywords:

AC motor drives, frequency drives, frequency inverter, frequency converter, variable frequency drives, variable speed drives, VFD, VSD, VVVF, soft starter, motor starter, motor controller, AC driver. high performance Frequency AC drives ,strong torque at low speed AC drive for fan and water pump,variable frequency drive ac motor controller for water pump,small size frequency converter, ac drive, VFD for water pump,ac drives for water pump,AC variable speed drives for water pump,variable frequency inverter VSD/VFD/VVVF AC Drive for water pump,380v 3 phase frequency inverter ac drive for water pump,Vector Control Ac drives for water pump. ac drive for water pump,400HZ general use vfd ac drive for water pump,frequency inverter, ac drive for water pump,inverter/ac motor drive for constant pressure water/pump/fan,high performance industrial AC drive for blower and water pump,made in china ac drive/vfd for water pump motor,sensorlesss vector control AC drive for water pump,high starting torque frequency inverter, VFD, AC drive for water pump

VTP6 series vector control inverter adopt advanced open- loop vector control arithmetic, strong overload output capacity, meet industry clients requirements of high performance and high reliable. can be widely used for speed control accuracy, torque response

speed, low-frequency output characteristics and other situations with higher requirements.

1.Have fast ,successive ,current limiting function, to ensure the load doesn't trip, and have a large output torque

2.3 road A/D sampling, suitable for most industrial control,It can set flexibly, and improve field application.

3.High quality of the algorithm,no matter open-loop vector, or V/F control,all of them can reach control requirements at proper speed, and the low frequency torque is large and stable.

4.Support torque control, In the V/F control way, It has current speed tracking, when V/F separate, It can eliminate the light load oscillation effectively, and so on,the maximum output frequency can reach 3200HZ.

5.Unique instantaneous stop and non-stop function,It can quickly decelerate stopping when power off, to prevent the machine from inertial rotation for a long time, more secure, can quickly complete the commissioning.

Specification

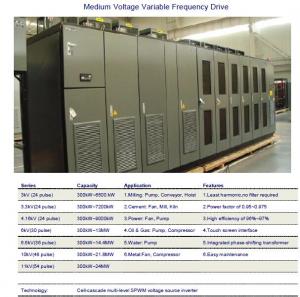

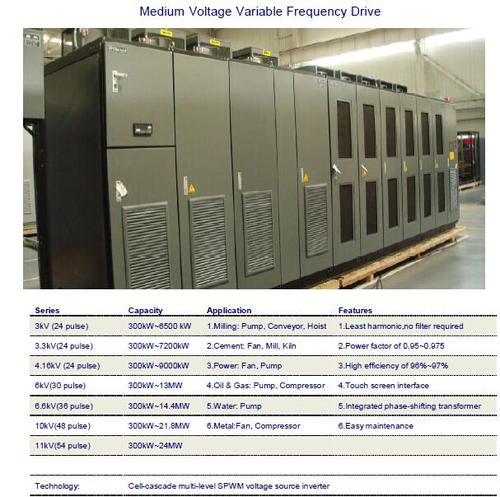

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: Is it possible to use a different laptop's power adapter?

- For the power adapter, whether access to equipment, the following aspects of the measurement standards: Interface form The interface plug and socket used must be dimensioned. Voltage size The output voltage of the adapter is the same as the required voltage of the connected device (eg notebook). Inconsistencies may not be able to start or burn the device properly. Current or power The power of the adapter is greater than the maximum power required by the device. Power is not enough, may cause the voltage to drop, the adapter is hot, or burn the adapter. More than the above, the use of more power of the power adapter, while meeting the interface and voltage conditions, it can be replaced.

- Q: My Lenovo v450 laptop power adapter should be bad how to match?

- Lenovo V450 laptop power adapter is broken, the warranty period is not artificially damaged can be directly to the Lenovo aftermarket replacement adapter can be outside the warranty period to pay maintenance, it is recommended to use the original power adapter the best. Laptop charger (Laptop Charger), that is, laptop charger. The traditional notebook charger can only output a single voltage to a type of notebook computer charging, the industry called the traditional notebook power adapter for the single band notebook charger (mainly in order to distinguish between the universal notebook charger.)

- Q: How can a variable speed multi - speed three - phase asynchronous motor be controlled by a frequency converter?

- Yes, but it is not necessary, if it is old motor that is another matter, tell you that you can use, but can not be in the frequency conversion process for the pole, this will cause the inverter protection or failure

- Q: Laptop power adapter leakage

- Not a leakage of electricity, switching power supply design is the need for anti-interference caused by the leakage current, a lot of adapters have this phenomenon, but no harm to the human body is safe, you do not have to buy to replace, the original is good. If you have a protective ground at home, then you can not feel the leakage, because the leakage current from the protection of the ground to the earth, and really leak, then your home leakage protector on the trip.

- Q: Variable frequency pump pressure in the very low flow instability, why?

- From the performance curve, the flow becomes smaller, the combination of pressure and frequency adjustment flow will only stabilize the flow at a small value, the pressure will be reduced, because the work point will move down.

- Q: How does the variable frequency motor output torque at very low frequencies?

- Low frequency, the motor torque is relatively low, generally VF inverter performance is good or bad, the price level reflected in this time. But there is torque to enhance the function, it will not move without moving. If no load can not start, check the motor card and other mechanical problems such as whether there is a problem.

- Q: Laptop power adapter output voltage is not the same as the current? What's the effect?

- I would like to elaborate on the basic principle of the large standard current power supply can replace the small standard current power supply. Some friends have misunderstood, that a large nominal current power will burn books, because the current big thing. In fact, how much current in the same voltage depends on the load, that is, the work of the books, when the books of high-load operation, the current larger, the books into the standby time, the current is smaller, in short, On the voltage divided by the equivalent resistance of the books. Large nominal current power supply has enough current margin, will not be replaced by a small standard current power supply after the overheating or output voltage is too low. On the contrary, with a small current power supply instead of high current power on the existence of the above risks. But some friends with 56w power supply instead of 72w with no problem, because the power adapter is usually designed to leave a certain margin, the load power should be less than the power supply,

- Q: How do I select a drive? Which brand is better

- ?Ampang letter company can provide different types of inverter, the user can according to their actual process requirements and the use of occasions to choose different types of frequency converter. When selecting the inverter, note the following precautions: ????1, according to the load characteristics of the inverter, such as the load for the constant torque load; fan, pump load should be selected AM300 inverter. ????2, select the inverter should be the actual motor current value as the basis for selection of the inverter, the motor rated power can only be used as a reference. Also should take full account of the output of the inverter contains high harmonics, will cause the motor power factor and efficiency will be bad. Therefore, with the inverter to the motor power supply and power grid power supply compared to the motor current increased by 10% and the temperature increase of about 20%. Therefore, in the choice of motor and inverter, should take into account the situation, the appropriate margin to prevent the temperature rise is too high, affecting the motor life. ????3, the inverter to long cable operation, this time should take measures to suppress the long cable to the ground coupling capacitor, to avoid the inverter output is not enough. So the inverter should be amplified or selected to install the output reactor at the output of the inverter.

- Q: Jd1a-40 motor speed controller and how to connect the motor

- Speed ??control motor wiring method: 3.4.5 is the terminal of the tachogenerator (U / V / W) from the right-to-left order of 1.2 for the excitation coil (F1 / F2) terminal, from the extended end of the speed motor (electromagnetic clutch) Master 7 plugs on the air plugs (governor): terminal 1.2 for the 220v input, 3.4 on the speed of the motor on the excitation coil, 5.6.7 speed motor on the tachogenerator. Motor speed control method: The speed regulating motor is to change the speed of the motor by using the series, voltage, current, frequency and so on of the motor to make the thyristor voltage regulation method the best.

- Q: First reduce the frequency of about one-third of the test, not the case, then appropriate adjustments!

- And the inverter is connected to the positive and negative bk-dk electrical Han Han device,

Send your message to us

High Voltage Frequency Drive 6KV 1120KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords