High Tensile Deformed Bar Grade E40_E60_E75

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Tensile Deformed Bar Grade E40_E60_E75

Details of High Tensile Deformed Bar Grade E40_E60_E75

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of High Tensile Deformed Bar Grade E40_E60_E75

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

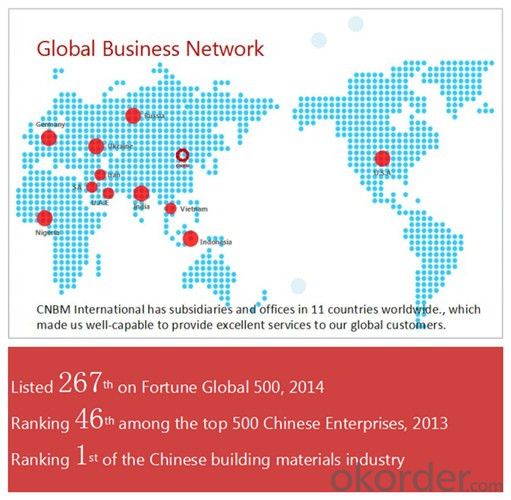

CNBM Introduction of High Tensile Deformed Bar Grade E40_E60_E75 Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of High Tensile Deformed Bar Grade E40_E60_E75

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel include stainless steel, tool steel, and high-speed steel.

- Q: What are the different surface treatment techniques for special steel?

- There are several surface treatment techniques for special steel, including electroplating, hot-dip galvanizing, powder coating, and passivation. Electroplating involves depositing a thin layer of metal onto the steel surface to improve its corrosion resistance. Hot-dip galvanizing involves immersing the steel in molten zinc to create a protective coating. Powder coating involves applying a dry powder to the steel surface, which is then cured to create a durable and decorative finish. Passivation is a chemical process that removes impurities from the steel surface, enhancing its corrosion resistance.

- Q: What are the different types of case-hardening steel?

- There are several types of case-hardening steels, including carburizing steels, nitriding steels, cyaniding steels, and induction hardening steels.

- Q: What are the cost implications of using special steel?

- Using special steel can have significant cost implications. Special steels are often more expensive compared to standard steels due to their specific properties and manufacturing processes. The cost of special steel can vary depending on factors such as the alloy composition, production techniques, and market demand. Additionally, using special steel may require specialized tools, equipment, and skilled labor, which can further increase the overall cost. However, it is important to consider the long-term benefits and potential cost savings that can be achieved by using special steel, such as improved durability, corrosion resistance, and enhanced performance in specific applications.

- Q: How is special steel used in the production of molds and dies?

- Special steel is used in the production of molds and dies due to its exceptional properties, such as high hardness, wear resistance, and heat resistance. These characteristics make it ideal for shaping and forming various materials, including metals and plastics. Special steel can withstand the high pressures and temperatures involved in the molding and die casting processes, ensuring durability and precision in the production of molds and dies.

- Q: How is free-cutting steel used in the manufacturing of screws and bolts?

- Free-cutting steel is used in the manufacturing of screws and bolts due to its exceptional machinability. It contains elements such as sulfur, phosphorus, lead, or selenium that act as lubricants during the cutting and machining process. These elements help to break the chips and reduce the friction between the metal and the cutting tool, resulting in improved efficiency and reduced tool wear. This type of steel enables faster production rates and higher precision in screw and bolt manufacturing.

- Q: How does special steel comply with international standards?

- Special steel is a type of steel that is specifically designed and manufactured to possess exceptional properties and performance characteristics. When it comes to complying with international standards, special steel undergoes a rigorous process to ensure its quality and adherence to the established norms. Firstly, special steel production adheres to international standards through the selection of raw materials. The composition and quality of the raw materials used in the manufacturing process are carefully controlled and tested to meet the specifications outlined by international standards organizations. This ensures that the special steel produced is of the desired quality and possesses the required mechanical properties. Secondly, special steel manufacturers follow standardized production processes. These processes are designed in accordance with international guidelines and standards to guarantee consistency and traceability. Through the use of advanced technologies and quality control measures, special steel manufacturers can monitor and control every stage of production, from melting and casting to rolling and heat treatment. This ensures that the final product meets the required standards in terms of chemical composition, mechanical properties, and dimensional tolerances. Furthermore, special steel undergoes stringent testing and inspection procedures to validate its compliance with international standards. This includes various destructive and non-destructive testing methods such as ultrasonic testing, hardness testing, and microstructure analysis. These tests are conducted by certified laboratories and independent third-party agencies to ensure unbiased and accurate results. In addition, special steel manufacturers often have their production processes and quality management systems audited and certified by recognized bodies, such as ISO (International Organization for Standardization), to demonstrate their commitment to compliance with international standards. It is also worth mentioning that special steel manufacturers actively participate in international standardization committees, such as ASTM International and the International Organization for Standardization (ISO). By engaging in these committees, they can contribute to the development and revision of international standards, ensuring that their products remain up to date and in line with the latest industry requirements. In conclusion, special steel complies with international standards through careful selection of raw materials, adherence to standardized production processes, rigorous testing and inspection procedures, and active participation in international standardization committees. By following these measures, special steel manufacturers demonstrate their commitment to producing high-quality products that meet the stringent requirements of international standards.

- Q: How does bearing steel contribute to the manufacturing of bearings?

- Bearing steel is a crucial material in the manufacturing of bearings as it provides the necessary strength, durability, and wear resistance required for the efficient operation of bearings. The high carbon content in bearing steel enhances its hardness and strength, ensuring that the bearings can withstand heavy loads, high speeds, and extreme operating conditions. Additionally, the unique composition and heat treatment of bearing steel enable it to maintain dimensional stability and minimize friction, leading to improved performance and longer life of the bearings.

- Q: How is high-strength tool steel used in the production of heavy-duty tools?

- High-strength tool steel is utilized in the production of heavy-duty tools due to its exceptional hardness, toughness, and wear resistance properties. This steel is specifically engineered to withstand high stress and extreme conditions, making it ideal for manufacturing tools that require durability and longevity. Heavy-duty tools such as drills, chisels, hammers, and cutting tools often require high-strength tool steel to ensure they can endure rigorous use and maintain their sharpness and functionality over time.

- Q: How does special steel contribute to the shipbuilding industry?

- Special steel plays a crucial role in the shipbuilding industry by providing enhanced strength, durability, and corrosion resistance to ships. It allows for the construction of lighter and more fuel-efficient vessels without compromising on structural integrity. Additionally, special steel enables the development of advanced ship components, such as propellers, hulls, and offshore structures, which can withstand harsh marine environments and ensure safer and more reliable operations at sea.

Send your message to us

High Tensile Deformed Bar Grade E40_E60_E75

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords