High Temperature Polyester Silicone Masking Tape with Packaging Tape Backing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Applications

1. Anodizing

2. Electronic Assembly

3. General Purpose Masking

4. Masking Electronic Components

5. Powder Coating

6. Plating

7. Photo Splicing

8. Shipping and Packaging

9. Plasma spray

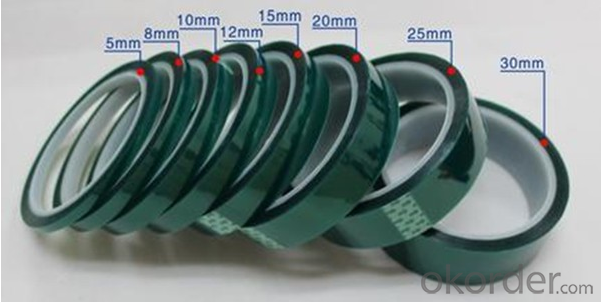

2.product show

3.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

4.Our service

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

5.FAQ

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. Packaging tape is available in various lengths to accommodate different packaging needs. Common lengths for packaging tape include 55 yards, 110 yards, and 1000 yards, although other lengths may be available as well. The length of the packaging tape you choose depends on the size and quantity of packages you plan to seal. It is important to consider the length of packaging tape needed to ensure you have enough to securely seal your packages without running out.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, there are a few things you can do: 1. Use a tape dispenser: A tape dispenser helps ensure a smooth application of tape, reducing the chances of it wrinkling. It also provides better control while taping, making it easier to keep the tape straight and tight. 2. Apply the tape with tension: When applying the tape, pull it tightly as you stick it down. This helps prevent any slack or loose areas that could cause wrinkling. Be careful not to stretch the tape too much, as it may lose its adhesive properties. 3. Use the right type of tape: Different types of packaging tape have different adhesive properties and thicknesses. Choosing a high-quality tape specifically designed for packaging can help minimize wrinkling. Additionally, consider using a tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, make sure the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or not adhere properly. Clean the surface thoroughly and dry it before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Avoid using the tape in extremely cold or hot environments. If possible, store the tape in a controlled temperature area before use. 6. Apply pressure: After applying the tape, run your hand or a roller over it to ensure good adhesion. This helps smoothen out any potential wrinkles or bubbles and ensures that the tape is securely attached. By following these tips, you can significantly reduce the chances of packaging tape wrinkling, resulting in a neater and more secure package.

- Q: What are the considerations for using packaging tape on painted surfaces?

- When using packaging tape on painted surfaces, it is important to consider the type of paint used and its durability. Some paints may not adhere well to the tape, causing it to peel off and damage the surface. Additionally, strong adhesive tapes can leave behind residue or even strip off the paint when removed. Therefore, it is advisable to test a small inconspicuous area before applying the tape extensively and to opt for low adhesive or painter's tape for better results.

- Q: Can packaging tape be used for sealing glass containers?

- Indeed, glass containers can be sealed using packaging tape. Packaging tapes are specifically engineered to offer a robust and reliable seal on diverse surfaces, glass included. When applied correctly, the tape adheres firmly to the glass, forming a secure seal that safeguards the container's contents. Nonetheless, it is crucial to acknowledge that not all packaging tapes are suitable for glass containers. It is advisable to utilize a tape explicitly designed for glass or a heavy-duty packaging tape with exceptional adhesive properties to guarantee an effective seal.

- Q: How do I remove packaging tape residue?

- There are a few simple methods you can try to remove packaging tape residue: 1. Rubbing alcohol can be used. Dampen a clean cloth or paper towel with rubbing alcohol and gently dab the residue. Allow it to sit for a few minutes before wiping away the residue. Repeat if needed. 2. Consider using Goo Gone or a similar adhesive remover. Apply a small amount of adhesive remover to a cloth or paper towel and gently rub the residue. Let it sit for a minute or two, then wipe away the residue using a clean cloth. 3. Warm soapy water is effective as well. Mix a few drops of dish soap with warm water. Dampen a cloth or sponge with the mixture and gently rub the residue. Rinse the area with clean water and thoroughly dry it. 4. Heat can be used for hard surfaces like glass or plastic. Use a hair dryer on a low setting and hold it a few inches away from the residue. Once the adhesive becomes soft, gently scrape it off using a plastic scraper or your fingernail. Remember to test any method on a small, inconspicuous area first to ensure it does not damage the surface.

- Q: What are the benefits of using double-sided packaging tape?

- There are several benefits of using double-sided packaging tape. Firstly, it provides a strong and secure bond between two surfaces. This makes it ideal for packaging applications where you need to ensure that the contents stay in place during transit or storage. The double-sided tape creates a strong adhesive bond that holds the packaging materials together, minimizing the risk of items shifting or becoming damaged. Secondly, double-sided packaging tape is versatile and can be used for various purposes. It can be used to seal boxes, attach labels or documents, or even mount lightweight objects. This versatility makes it a valuable tool for both personal and professional packaging needs. Another benefit is that double-sided packaging tape is easy to use. Unlike traditional packaging tapes that require you to apply adhesive on both surfaces, double-sided tape already has adhesive on both sides, making it a convenient option. It saves time and effort as you simply need to peel off the backing and apply the tape to the desired surface. Furthermore, double-sided packaging tape offers a neat and clean appearance. Since the tape is hidden between the surfaces it is bonding, it creates a seamless look without any visible tape lines. This can be particularly useful when packaging gifts or products that need to maintain a professional and presentable appearance. Lastly, double-sided packaging tape is often designed to be durable and long-lasting. It can withstand various environmental conditions, such as temperature changes, humidity, or exposure to moisture, without losing its adhesive properties. This ensures that your packaging remains intact and secure for an extended period. In summary, the benefits of using double-sided packaging tape include strong adhesion, versatility, ease of use, a clean appearance, and durability. Whether you are packaging items for personal or professional purposes, double-sided packaging tape can provide a reliable and efficient solution.

- Q: Can packaging tape be used for sealing plastic bottles?

- Yes, packaging tape can be used for sealing plastic bottles. Packaging tape is designed to provide a secure and tight seal on various surfaces, including plastic. It offers strong adhesion and can effectively keep the contents of a plastic bottle secure and protected. However, it's important to note that packaging tape may not be as effective as specialized bottle sealing options such as bottle caps or seals. These alternatives are specifically designed for plastic bottles and offer a more reliable and leak-proof seal. Therefore, while packaging tape can be used as a temporary solution, it is recommended to use proper bottle sealing options for long-term storage or transportation of liquids.

- Q: What are the considerations for using packaging tape on wooden surfaces?

- When using packaging tape on wooden surfaces, it is important to consider the type of tape being used and its adhesive properties. Opt for a tape specifically designed for use on wood to prevent any potential damage or residue. Additionally, ensure that the wooden surface is clean and dry before applying the tape to ensure proper adhesion. It is also advisable to test a small, inconspicuous area of the wood first to ensure that the tape does not cause any discoloration or damage.

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Can packaging tape be used for sealing food containers?

- Using packaging tape to seal food containers is not recommended. Although it may effectively secure boxes and packages, it is not suitable for use with food. It is important to seal food containers with materials specifically designed for food contact, such as food-grade plastic wrap, aluminum foil, or airtight reusable food storage containers. Applying packaging tape to food containers can introduce hazardous chemicals or adhesives that may contaminate the food, compromise its quality, or pose health risks. Therefore, it is crucial to prioritize food safety by using approved materials exclusively for sealing food containers.

Send your message to us

High Temperature Polyester Silicone Masking Tape with Packaging Tape Backing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords