Custom Packaging Tape NYC - Masking Adhesive Tape High Temperature Polyester Silicone

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Features

♦ High temperature resistant

♦ Silicone adhesive,no glue residue

♦ Best die-cut tape to mount various of precison molded parts

♦ Powder coating masking

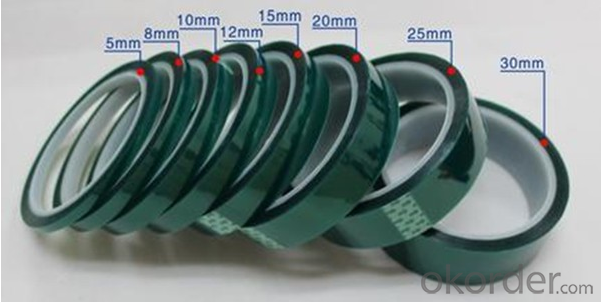

2.product show

3.Why choose us

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

4.Our Services

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

5.FAQ

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: How about the price of tape?

- Each tape price calculation method: the tape industry usually use "yuan / square meter" to calculate the price of adhesive tape, calculate the price of adhesive tape formula: "each tape price = width (m) * length (m) * square price"". The price of the adhesive tape needs to be variable according to the cost, because the BOPP film and glue belong to the petroleum products, and the price is uncertain.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various surfaces, including those that are not completely flat or smooth. Its adhesive properties make it effective in securing packages with irregular surfaces, ensuring they remain sealed during transit or storage.

- Q: Can packaging tape be used for sealing bubble wrap?

- Certainly, bubble wrap can be sealed using packaging tape. Frequently employed as a safeguarding packaging substance for delicate objects, bubble wrap is often secured and sealed with packaging tape. By affixing packaging tape to the edges and joints of the bubble wrap, one can successfully seal it, guaranteeing its integrity during transportation or storage. The adhesive on packaging tape establishes a sturdy connection, assuring that the bubble wrap remains in position and offers supreme protection for the items it envelops.

- Q: What are the alternatives to packaging tape for sealing packages?

- Sealing packages can be done using various alternatives to packaging tape. Here are a few choices available: 1. Gummed tape: Also known as water-activated tape, gummed tape is a well-liked substitute. It is created from paper or reinforced material and necessitates the use of water to activate the adhesive. Gummed tape forms a sturdy bond with the package and ensures a seal that is evident if tampered with. 2. Strapping: Strapping is commonly employed for securing heavy or bulky packages. It involves the use of plastic or metal straps to tightly hold the package together. Strapping can offer more security than tape, particularly for larger or irregularly shaped items. 3. Shrink wrap: Shrink wrap is a plastic film that can be wrapped around the package and sealed by applying heat. As the film shrinks, it conforms tightly to the shape of the package, ensuring a secure seal. Shrink wrap is frequently used for wrapping pallets or bundling multiple items together. 4. Adhesive labels: An alternative to tape for sealing packages is adhesive labels. These labels possess a strong adhesive backing that adheres to the package, guaranteeing a secure seal. They are particularly useful for small or lightweight items. 5. Twine or string: For lighter packages, twine or string can be used to secure the contents. Simply wrap the string around the package multiple times and tie it securely. Although this method may not be as strong as tape, it can be a cost-effective and environmentally friendly option. Ultimately, the selection of an alternative to packaging tape depends on the package's size, weight, and characteristics. Each option carries its own advantages and disadvantages, so it is important to consider the specific shipment requirements before making a decision.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Yes, packaging tape can definitely be used for sealing household or kitchen items. It is a versatile adhesive tape that is commonly used for sealing cardboard boxes, but it can also be utilized for sealing various items in the household or kitchen. Whether you need to seal food containers, plastic bags, or even small appliances, packaging tape can provide a strong and secure seal. It is important to ensure that the surface is clean and dry before applying the tape to maximize its adhesive strength.

- Q: How does packaging tape perform in freezing temperatures?

- Packaging tape typically performs well in freezing temperatures as it is designed to withstand a wide range of temperatures. However, it is important to ensure that the tape is applied and adhered properly to ensure its effectiveness in cold conditions.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: Is packaging tape resistant to oil or grease?

- Yes, packaging tape is generally resistant to oil or grease.

- Q: Can packaging tape be used for sealing packages for shipping?

- Yes, packaging tape can be used for sealing packages for shipping. Packaging tape is specifically designed to securely seal packages and keep them intact during transit. It provides a strong and durable bond that can withstand the rigors of shipping and handling. Whether you are shipping small or large packages, packaging tape is an essential tool to ensure that your items are properly sealed and protected during transportation.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to provide reliable adhesion and sealing under various conditions, including high-pressure environments. In high-pressure conditions, such as during shipping or transportation, packaging tape performs exceptionally well due to its strong adhesive properties and durable construction. The adhesive used in packaging tape is typically a pressure-sensitive adhesive (PSA), which means it adheres to surfaces when pressure is applied. This allows the tape to create a secure bond with the packaging material, even under high-pressure conditions. The tape's adhesive strength ensures that it remains firmly attached to the package, preventing any potential damage or tampering during transit. Moreover, packaging tape is often made from sturdy materials such as polypropylene or PVC, which further enhances its performance in high-pressure conditions. These materials provide excellent tensile strength, meaning they can withstand significant pressure without breaking or tearing. This ensures that the tape maintains its integrity and keeps the package sealed and protected. Additionally, packaging tape is often resistant to moisture, temperature changes, and other environmental factors that can impact its performance. This resistance helps the tape maintain its adhesive strength and structural integrity even in demanding conditions, including high-pressure environments. Overall, packaging tape is specifically engineered to perform well in high-pressure conditions. Its strong adhesive properties, durable materials, and resistance to various environmental factors make it a reliable choice for ensuring package integrity and protection during shipping or transportation.

Send your message to us

Custom Packaging Tape NYC - Masking Adhesive Tape High Temperature Polyester Silicone

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords