High Temperature Insulation Fiberglass Needle Mats

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

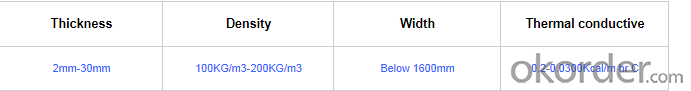

Description: Our high-quality Glass Fiber Mat is made by means of needle punching process with the mixed silicic acid glass fiber, that is chopped from long glass fiber. It is fire retardant, high temperatures resistant, good chemical and abrasion resistant, electrically and acoustically insulating and so on. The main applications are soundproof, heat resistant, heat protection, thermal insulation on pipes, insulator for high temperatures, or other industrial areas.

Features: high temperature, chemical, and abrasion resistance, fire retardant

Application: Fiberglass Mesh Cloth, resistant high temperatures

PRICE: USD2 per kilogram

UNIT: Kilogram

MOQ: 100 KGS

Width: 1m,1.2m,1.5m or customized

Yarn Type: E-glass

Standing temperature: up to 650℃

Product name: E Glass Needle Mat

Roll length: 50 meter or customized

Color: white

Weave Type:conventional

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass

Thickness: 20mm or customized

Size: can be customized

Supply ability: 200000 Kilogram/Kilograms per Month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Technology: nonwoven, laminating and needle-punched

- Q: How does fiberglass fabric perform in shear strength?

- Fiberglass fabric has excellent shear strength performance. Due to its composition of intertwined glass fibers, it possesses strong resistance to forces applied parallel to its surface. The interlocking fibers create a strong and rigid structure that allows it to withstand shear stresses and prevent deformation or failure. This makes fiberglass fabric highly suitable for applications where shear strength is important, such as in the construction of lightweight, high-strength composites, reinforcement of concrete, and the manufacturing of various industrial products. Additionally, fiberglass fabric's shear strength is not significantly affected by exposure to moisture, chemicals, or high temperatures, making it a durable and reliable material for a wide range of applications.

- Q: Can fiberglass fabric be used for reinforcement in power plant tanks?

- Indeed, power plant tanks can benefit from the utilization of fiberglass fabric as reinforcement. Renowned for its robustness and longevity, fiberglass fabric finds widespread application in multiple industries, including power plants, for reinforcement purposes. This material boasts remarkable tensile strength and exceptional resistance to corrosive elements, chemicals, and extreme temperatures. Moreover, its lightweight nature and effortless manageability render it an ideal option for reinforcing power plant tanks. By bolstering the structural integrity of the tanks, fiberglass fabric not only fortifies them but also safeguards against potential leaks or breakdowns.

- Q: Is fiberglass fabric resistant to birds?

- No, fiberglass fabric is not inherently resistant to birds. While fiberglass is a strong and durable material, it can still be damaged by birds. They may peck at or scratch the surface of the fabric, causing minor to moderate damage. Additionally, birds may build nests using fiberglass fabric if they find it suitable for their needs. However, fiberglass fabric is not a preferred material for birds as it lacks the softness and flexibility they typically seek for nesting. Therefore, while it may not be completely resistant to birds, fiberglass fabric is less likely to be heavily targeted or extensively damaged by them compared to other materials.

- Q: How does fiberglass fabric perform in vibration isolation applications?

- The excellent performance of fiberglass fabric in vibration isolation applications is well-known. This material possesses inherent properties, including high tensile strength, flexibility, and low thermal conductivity, which make it perfect for effectively isolating vibrations. When exposed to vibrations, fiberglass fabric absorbs and dampens the resulting energy, thereby reducing the transmission of vibrations from one component to another. This ability to absorb vibrations is crucial in industries such as automotive, aerospace, and construction, where minimizing vibrations is vital for optimal performance and safety. Additionally, the high tensile strength of fiberglass fabric ensures that it can withstand the forces and stresses associated with vibrations without tearing or breaking. This strength is important for maintaining the fabric's integrity and effectiveness as a vibration isolator since any damage to the fabric could compromise its performance. Furthermore, the flexibility of fiberglass fabric allows it to conform to various shapes and surfaces, ensuring a secure and snug fit in vibration isolation applications. This flexibility enables the fabric to effectively isolate vibrations across a wide range of frequencies and amplitudes, making it a versatile solution for different vibration control needs. Lastly, the low thermal conductivity of fiberglass fabric is advantageous in vibration isolation applications where temperature differences exist. By minimizing heat transfer, the fabric helps maintain the stability and performance of isolated components, especially in environments with extreme temperatures. In conclusion, fiberglass fabric is highly effective in vibration isolation applications due to its ability to absorb and dampen vibrations, high tensile strength, flexibility, and low thermal conductivity. Its effectiveness, versatility, and durability make it the preferred choice for industries that require efficient vibration control.

- Q: Can fiberglass fabric be used for insulation in telecommunications cables?

- Yes, fiberglass fabric can be used for insulation in telecommunications cables. Fiberglass fabric has excellent thermal insulation properties, making it an ideal choice for insulating cables that carry electrical signals. It can withstand high temperatures and is resistant to fire, chemicals, and abrasion, providing a reliable and durable insulation solution for telecommunications cables. Additionally, fiberglass fabric is lightweight, flexible, and easy to handle, making it convenient for cable installation and maintenance. Its high dielectric strength also ensures that it does not interfere with the electrical signals transmitted through the cables. Therefore, fiberglass fabric is commonly used as an insulation material in telecommunications cables to protect the cables and ensure efficient and reliable signal transmission.

- Q: Are fiberglass fabrics suitable for use in the oil and gas industry?

- Fiberglass fabrics are indeed suitable for utilization in the oil and gas sector, offering numerous benefits that make them highly appropriate for diverse applications within this industry. To begin with, the resistance of fiberglass fabrics to corrosion and chemicals is exceptionally high, rendering them perfect for deployment in environments where exposure to oil, gas, and other corrosive substances is prevalent. This resistance ensures the longevity and durability of the fabric, minimizing the need for frequent replacements and maintenance. Furthermore, the thermal insulation properties of fiberglass fabrics are excellent, a crucial characteristic in the oil and gas industry, where encountering high temperatures is common. These fabrics have the capacity to endure extreme heat and safeguard equipment and personnel from thermal hazards. In addition, fiberglass fabrics possess remarkable traits of being lightweight, yet strong and flexible, simplifying their handling and installation. This feature proves particularly advantageous in applications that necessitate the creation of intricate shapes or structures, such as insulation jackets or protective covers. Moreover, fiberglass fabrics exhibit commendable electrical insulation properties, thereby reducing the risk of electrical hazards in oil and gas operations. They can serve as insulation materials for electrical equipment, cables, and pipelines, ensuring safe and dependable operations. Finally, fiberglass fabrics possess a high dielectric strength, enabling them to withstand high voltage and prevent electrical arcing. This quality holds exceptional importance in the oil and gas industry, where the potential for electrical accidents can be significant. To summarize, fiberglass fabrics are highly suitable for use in the oil and gas industry due to their corrosion resistance, thermal insulation properties, lightweight and flexible nature, electrical insulation capabilities, and high dielectric strength. These attributes establish them as dependable and efficient materials for a wide range of applications within this industry.

- Q: How does fiberglass fabric compare to other types of fabrics?

- Distinguishing itself from other fabric types, fiberglass fabric boasts several distinct characteristics. Firstly, its incredible strength and durability render it ideal for situations where robustness is paramount, such as in industrial settings or outdoor equipment. Withstanding heavy loads and stress without tearing or stretching, it exhibits a commendable tensile strength. Secondly, fiberglass fabric exhibits remarkable resistance to heat and fire. Possessing a high melting point and a propensity to resist catching fire, it stands as a suitable option for applications concerned with fire safety, such as insulation materials or protective clothing. Moreover, fiberglass fabric showcases resistance to chemicals and corrosion. Unreactive towards most chemicals, acids, or alkalis, it finds suitability in environments frequently exposed to corrosive substances, such as chemical plants or laboratories. Furthermore, fiberglass fabric offers the advantage of being lightweight and flexible. Despite its strength, it remains non-bulky and easy to handle. This flexibility enables its application in various scenarios that require a certain degree of flexibility, including the construction of curved surfaces or the manufacturing of composite materials. Nevertheless, fiberglass fabric does have some drawbacks. It lacks the comfort and softness of other fabric types, diminishing its appeal in certain applications like clothing or upholstery. Additionally, it tends to be more costly than certain alternative fabric options. Overall, fiberglass fabric emerges as an exceptionally versatile material, embodying exceptional strength, durability, heat resistance, chemical resistance, and flexibility. While it may not be universally suitable, it represents an excellent choice for those seeking its unique properties.

- Q: How is fiberglass fabric cut?

- Fiberglass fabric is typically cut using specialized tools such as scissors, utility knives, or rotary cutters. The fabric is laid flat on a cutting surface, and the desired shape or size is traced onto it. The cutting tool is then used to carefully follow the traced lines, ensuring a clean and precise cut. It is important to use sharp tools and take safety precautions due to the fibrous nature of the fabric.

- Q: What are the different weave styles available for fiberglass fabric?

- Fiberglass fabric offers a variety of weave styles, each with its own distinct qualities and uses. Among the most popular are plain weave, twill weave, satin weave, and leno weave. 1. Plain weave, the most common style, features a straightforward over-under pattern. Warp yarns pass alternatively over and under weft yarns, resulting in a balanced and stable fabric. Its versatility makes it suitable for numerous applications. 2. Twill weave showcases a diagonal line pattern on the fabric surface. By passing the weft yarn over multiple warp yarns before going under one or more, twill weave fabrics offer superior strength and durability, making them perfect for high-performance applications. 3. Satin weave is known for its smooth and glossy appearance. The weft yarn passes over several warp yarns before going under one, creating a high number of floats and a silky texture. Satin weave fabrics are lightweight, flexible, and drape beautifully, making them ideal for achieving a refined and elegant finish. 4. Leno weave is a unique style that creates an open mesh structure. Adjacent warp yarns are twisted together and secured with a weft yarn, resulting in high porosity and excellent breathability. Leno weave fabrics are commonly used in filtration and composite reinforcement applications. These are just a few examples of the weave styles available for fiberglass fabric. The choice of weave depends on specific requirements, such as strength, weight, flexibility, and aesthetics.

- Q: Can fiberglass fabric be used for heat-resistant blankets?

- Yes, fiberglass fabric can be used for heat-resistant blankets. Fiberglass is a highly heat-resistant material that can withstand high temperatures without melting or degrading. It has excellent thermal insulation properties, making it an ideal choice for heat-resistant blankets. Fiberglass fabric blankets can be used in various applications, such as welding, foundries, fire protection, and heat shielding. They provide effective protection against heat, flames, and sparks, making them a reliable choice in environments where heat resistance is critical.

Send your message to us

High Temperature Insulation Fiberglass Needle Mats

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords