Fiberglass Needle Mat For Wholesales With New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Fiberglass needled mat is a filter material which has a reasonable structure and can bear high temperature.

1.Fiberglass needled mat is a filter material which has a reasonable structure and

can bear high temperature.

It not only has the excellent merit such as heat-isolation,

anti-corrosion, stable-size, minimum elongated shrinkage, high intensity;

but also the textile fiber of mat layer assumes the single textile fiber, three

dimensional pore structure, the hole rate is high, filtering the resistance to

the air small, is a kind of high speed and high effective of heat filter material.

Compares with other thermostable chemical fiber felt, has the special merit

such as below-price and more high heat-resistant and so on.

But its movement resistancemust be higher than

the common chemical fiber high-temperature filter material,

filtering the precision slightly low.

Feature:

1.E-glass , without binder, environment friendly

2.Good combustion insulation, sound absorption

3.Mcrocellular structure , high efficiency of dust absorption

4.abrasion resistance . dimension stability

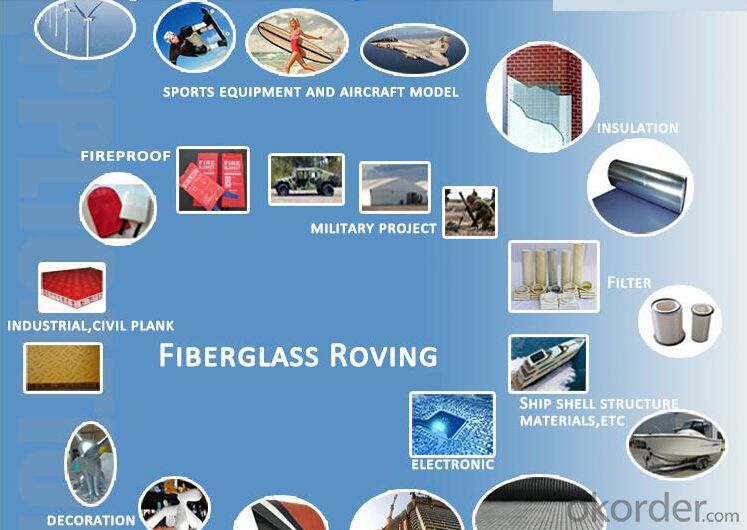

Application

Fiberglass needle felt/mat applied to Heat insulation and sound absorption of Auto exhausts system/construction(roof,walls,floor), Heat preservation/insulation of air conditioning, domestic appliance, Sound absorption and heat insulation of machinery, electronic products and so on .

Description

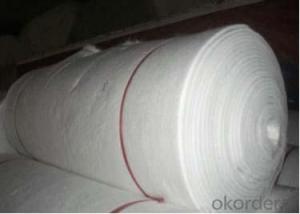

fiberglass needle felt/mat is made from inorganic e-glass.very small glass fibers are uniformly arranged on the belt, then needled togather by the advanced needle technology .so it form the unique 3D cellular structure.sound and thermal absorption . it is environmental friendly inorganic material , no binder added. without any smell and cancerogenic substance .

specification:

Incl | e-glass chopped strand matting | |

Item type | Fiberglass mat | |

Style | EMCL300 | |

Mass(g/m2) | 300±22 | |

Tensile Strength (N/150mm) | Longitudinal | ≥60 |

Transverse | ≥60 | |

Combustible matter content | 1.8%~8.5% | |

Width(mm) | 1040/1270 | |

Wet-out rate(s) | ≤80 | |

Moisture content | ≤0.50% | |

Storage :

The product should be stored in dry and cool place where is the best condition if has the temperature 5-35°C and the humidity 35-65°C. Unless use , the package must be kept intact in order to prevent moisture away .

Advantage

*Consistent thickness and stiffness

*Rapid impregnating and good compatibility with resin.

*Superior wet through with less air trap.

*Good mechanical properties and high strength of parts.

In addition: *for quality guarantee for e-glass chopped strand matting

*Reasonable price and best services.

*OEM service is welcome.

* Flexible delivery for sample and big order.

*many years working experience for production & Research and Development in this e-glass chopped strand matting field.

Transportation

*Express(UPS,DHL,Fedex,EMS,etc) is available.

*Sea and Air delivery is available

*welcome your agent to deal with e-glass chopped strand matting.

Delivery time

*General Sample order is in stock,OEM is allowable for 5-7days.

*Flexible delivery time can be negotiated and on time delivery is our consistent style.

product show

FAQ

1.Q: What specification do you have for E glass Fiberglass chopped strand mat ?

A: Now our normal specification of fiberglass mat have 45/50/55/60/90/100gsm, can be customized.

2.Q:How about the width?

A:The normal width is 1000mm, can be customized.

3.Q:How about the sample delivery?

A.Small sample is free of charge, sample ready time 3-5days.

4.Q:How about the delivery time?

A:It is depend on the order quantity, three 20'ft container around 20days.

- Q: Waterproof materials related to the raw materials which ah

- ④ metal waterproof material. Thin steel plate, galvanized steel plate, pressure plate, coated steel plate can be directly used as roof panels, for waterproof. A sheet of metal used in a basement or underground structure. Thin copper plate, thin aluminum plate, stainless steel plate can be made of structural deformation of the sealing water zone. Metal waterproof layer of the connection to be welded, and brushing rust protection paint.

Send your message to us

Fiberglass Needle Mat For Wholesales With New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches