Ductile Iron Taper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

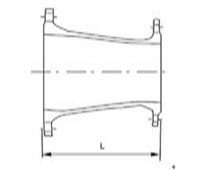

Double Socket Taper

K12

Available in T Type and K Type;

Size: DN80-2000

We are involved in the manufacture and supply of the Double Socket Taper. We manufacture these with the premium quality raw materials. Our Double Socket Tapers ensure high durability and strength. Our range of Double Socket Tapers caters to various industrial requirements. We offer these Double Socket Tapers in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter | L | Mass(kg) | ||

DN | dn | T Type | K Type | |

100 | 80 | 90 | 8.5 | 12.5 |

150 | 80 | 190 | 13.5 | 18.6 |

150 | 100 | 150 | 13.8 | 19.1 |

200 | 100 | 250 | 20.5 | 26.0 |

200 | 150 | 150 | 21 | 27.0 |

250 | 150 | 250 | 29 | 36.0 |

250 | 200 | 150 | 29 | 35.0 |

300 | 150 | 350 | 39.5 | 50.0 |

300 | 200 | 250 | 39.5 | 49.0 |

300 | 250 | 150 | 38.5 | 47.5 |

350 | 200 | 360 | 52 | 62.5 |

350 | 250 | 260 | 51 | 61.0 |

350 | 300 | 160 | 49.5 | 61.5 |

400 | 200 | 460 | 62 | 78.0 |

400 | 250 | 360 | 66 | 76.5 |

400 | 300 | 260 | 64 | 80.1 |

400 | 350 | 160 | 62 | 78 |

450 | 250 | 460 | 89.5 | 94.0 |

450 | 300 | 360 | 88.1 | 97.1 |

450 | 350 | 260 | 86 | 95 |

450 | 400 | 160 | 83.1 | 92 |

500 | 300 | 460 | 97 | 114 |

500 | 350 | 360 | 98 | 115 |

500 | 400 | 260 | 94 | 111 |

500 | 450 | 160 | 99.5 | 106 |

600 | 350 | 560 | 151 | 159 |

600 | 400 | 460 | 142 | 156 |

600 | 450 | 360 | 149 | 151 |

700 | 500 | 260 | 131 | 145 |

700 | 400 | 680 | 226 | 215 |

700 | 450 | 580 | 225 | 210 |

700 | 500 | 480 | 194 | 203 |

700 | 600 | 280 | 178 | 184 |

800 | 450 | 780 | 295 | 278 |

800 | 500 | 680 | 288 | 285 |

800 | 600 | 480 | 252 | 257 |

800 | 700 | 280 | 229 | 236 |

K12

Available in T Type and K Type;

Size: DN80-2000

Nominal Diameter | L | Mass(kg) | ||

DN | dn | T Type | K Type | |

900 | 500 | 880 | 360 | 358 |

900 | 600 | 680 | 341 | 339 |

900 | 700 | 480 | 318 | 327 |

900 | 800 | 280 | 288 | 294 |

1000 | 600 | 880 | 446 | 445 |

1000 | 700 | 680 | 427 | 422 |

1000 | 800 | 480 | 392 | 403 |

1000 | 900 | 280 | 354 | 368 |

1200 | 700 | 1080 | 699 | 667 |

1200 | 800 | 880 | 668 | 631 |

1200 | 900 | 680 | 630 | 591 |

1200 | 1000 | 480 | 570 | 580 |

1400 | 800 | 760 | 877 | 716 |

1400 | 900 | 660 | 906 | 710 |

1400 | 1000 | 560 | 1015 | 704 |

1400 | 1200 | 360 | 711 | 698 |

1600 | 1000 | 760 | 1427 | 960 |

1600 | 1200 | 560 | 1355 | 919 |

1600 | 1400 | 360 | 951 | 936 |

1800 | 1200 | 760 | - | 1238 |

1800 | 1400 | 560 | - | 1198 |

1800 | 1600 | 360 | 1235 | 1234 |

2000 | 1200 | 960 | - | 1620 |

2000 | 1400 | 760 | - | 1579 |

2000 | 1600 | 560 | - | 1503 |

2000 | 1800 | 360 | 1566 | 1565 |

Double Flanged Taper

K12

Concentric and Flat Type

PN10, PN16 and PN25 are available

Size: DN80-2000

We are involved in the manufacture and supply of the Double Flanged Taper. We manufacture these with the premium quality raw materials. Our Double Flanged Tapers ensure high durability and strength. Our range of Double Flanged Tapers caters to various industrial requirements. We offer these Double Flanged Tapers in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter | Length | Mass(kg) | |||

DN | dn | L | PN10 | PN16 | PN25 |

100 | 80 | 200 | 9.5 | 9.5 | 9.8 |

150 | 80 | 400 | 15.2 | 15.2 | 16.2 |

150 | 100 | 300 | 15.5 | 15.5 | 17 |

200 | 100 | 600 | 29.5 | 28 | 30.8 |

200 | 150 | 300 | 22 | 21.5 | 25.0 |

250 | 150 | 600 | 43 | 42.5 | 46.7 |

250 | 200 | 300 | 30 | 29.5 | 35.5 |

300 | 150 | 600 | 56 | 55 | 62 |

300 | 200 | 600 | 58.5 | 57 | 65 |

300 | 250 | 300 | 40.5 | 39.5 | 49.5 |

350 | 200 | 600 | 60.5 | 63.5 | 74.0 |

350 | 250 | 600 | 67 | 70 | 82.5 |

350 | 300 | 300 | 49.5 | 52 | 66.0 |

400 | 200 | 600 | 74.5 | 73 | 86.5 |

400 | 250 | 600 | 77.0 | 83 | 98.5 |

400 | 300 | 600 | 82 | 90 | 107 |

400 | 350 | 300 | 58 | 67.0 | 86.0 |

450 | 250 | 600 | 82 | 87 | 103 |

450 | 300 | 600 | 87 | 92 | 110 |

450 | 350 | 600 | 96 | 106 | 125 |

450 | 400 | 300 | 81 | 85 | 101 |

500 | 300 | 600 | 126 | 134 | 152 |

500 | 350 | 600 | 117 | 125 | 150 |

500 | 400 | 600 | 110 | 130 | 153 |

500 | 450 | 300 | 83.0 | 104 | 127 |

600 | 350 | 700 | 167 | 188 | 226 |

600 | 400 | 600 | 164 | 191 | 229 |

600 | 450 | 600 | 167 | 193 | 221 |

600 | 500 | 600 | 195 | 210 | 216 |

700 | 400 | 800 | 196 | 212 | 255 |

700 | 450 | 700 | 197 | 217 | 259 |

700 | 500 | 600 | 200 | 256 | 268 |

700 | 600 | 600 | 195 | 236 | 282 |

800 | 450 | 900 | 263 | 286 | 347 |

800 | 500 | 800 | 256 | 284 | 346 |

800 | 600 | 600 | 260 | 298 | 363 |

800 | 700 | 600 | 263 | 290 | 371 |

900 | 500 | 1000 | 338 | 370 | 443 |

900 | 600 | 800 | 318 | 360 | 436 |

900 | 700 | 600 | 321 | 352 | 444 |

900 | 800 | 600 | 308 | 352 | 462 |

1000 | 600 | 1000 | 422 | 490 | 583 |

1000 | 700 | 800 | 396 | 442 | 551 |

1000 | 800 | 600 | 399 | 448 | 575 |

1000 | 900 | 600 | 376 | 438 | 577 |

1200 | 700 | 1260 | 711 | 777 | 908 |

1200 | 800 | 1070 | 688 | 758 | 908 |

1200 | 900 | 880 | 652 | 726 | 887 |

1200 | 1000 | 790 | 586 | 692 | 879 |

1200 | 1100 | 600 | 566 | 655 | 850 |

1400 | 800 | 1590 | 1034 | 1105 | 1308 |

1400 | 900 | 1405 | 998 | 1074 | 1288 |

1400 | 1000 | 1220 | 961 | 1052 | 1236 |

1400 | 1100 | 1035 | 914 | 1005 | 1253 |

1400 | 1200 | 850 | 817 | 947 | 1199 |

1600 | 1000 | 1650 | 1424 | 1547 | 1802 |

1600 | 1100 | 1460 | 1377 | 1502 | 1774 |

1600 | 1200 | 1280 | 1324 | 1468 | 1745 |

1600 | 1400 | 910 | 1103 | 1273 | 1602 |

1600 | 1500 | 725 | 1073 | 1250 | 1594 |

1800 | 1100 | 1895 | 1910 | 2057 | 2392 |

1800 | 1200 | 1710 | 1858 | 2024 | 2363 |

1800 | 1400 | 1340 | 1701 | 1870 | 2263 |

1800 | 1500 | 1155 | 1610 | 1810 | 2216 |

1800 | 1600 | 970 | 1436 | 1664 | 2081 |

2000 | 1200 | 2140 | 2512 | 2705 | 3069 |

2000 | 1400 | 1770 | 2358 | 2553 | 3059 |

2000 | 1500 | 1585 | 2268 | 2494 | 3014 |

2000 | 1600 | 1400 | 2176 | 2404 | 2934 |

2000 | 1800 | 1030 | 1800 | 2079 | 2671 |

•Material :Ductile Cast Iron

•Size Range :DN 80 to DN 2000

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity : 50,000 tons

•Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

•Cement Interior:Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Packaging & Delivery:

| Packaging Detail: | package:wooden cases with plastic layer, wooden pallets with plastic layer , steel crates,steel strip |

| Delivery Detail: | within 20-30 days after receipt the 70% balance |

Usage:

It is used for the connection between the two different diameter of pipes.

- Q: The expansion type pipe joint and the sleeve type pipe joint difference, everybody looks at the picture, this is belongs to that kind of?

- The material of the pipe has a problem, it is a hose. So what kind of form do you have?. If the straitjacket of words, should belong to flaredfitting.

- Q: Or are you lobbying for a fire breathing dragon park in your neighborhood like I am?Since Winkie is just a baby I've been slapped with 4 law suits because all he wants to do is play with the dogs he doesn't mean to scorch them.

- if you notice cylinders are round. Completely, on the top and bottom. It is by using this cylindrical shape and also the density of the steel that makes it capable of withstanding such pressure.

- Q: is there an equation that someone can show me that gravitational waves travel at the speed of light. even electric fields if you will.

- They should all get pushed. But with how WWE likes to F things up I see all three becoming jobbers at the end of the year.

- Q: i think the top says it all but i want a pipe that is safe to smoke out of and not toxic even though smoke is bad for you anyways i don't see any point in killing myself quicker then i need to so i want something that don't burn doesn't make it taste nasty and isn't poisonous and is a household item or easy to get without spending money

- Stainless can be used for anything. Schedule 40 is same as the black iron you would use. The black iron pipe that is reccomended has a plastic coating and you wrap the joints with this really good tape and it lasts forever also. Just pay atention to the joints and use good pipe dope because it is dificult to get good threads with stainless unless you use a good threader. An advantage of stainless over plastic is you won't damage stainless schedule 40 with a shovel or tiller. BTW most areas won't allow galvanize or copper because the natural gas has sulphur in it and sulphur corrades both.

- Q: I use an electric heater in my room, and every time I turn it on, or any electric heater for that matter I get really sick at my stomach and a headache and it's real bad too like reach for the trash can kind of bad. I just feel weird over all. and I almost know it's the heater because I've turned it off and the symptoms disappeared almost immediately (It also got cold really fast too) and I turned it back on same thing. I've tried this with several heaters. but I really have to have something because the outside temp is below zero I believe and this is an old house with poor insulation.and I know I don't have Carbon Monoxide poisoning because I DO have a Gas stove in my bathroom (The old kind too) that I leave burning constantly, but I can sit around that thing all day and not feel any different unless I shut the door for a shower then I might get a little light headed but that only happened to me once and I was in there for a LONG time. plus we have a brand new Carbon Monoxide detector right by it.

- You've answered your question already. The only reason for speed bumps is to keep drivers at or below the speed limit for that area. Usually to protect children and pedestrians.

- Q: I thought about taking an old blanket and stuffing it inside my window to keep cold air out. I need some more tips like this; help!

- If there's a fire, he has to pull it regardless. Delays are dangerous in emergencies.

- Q: Hot tap water pipe joint leakage, what method can be repaired?

- The original hot connection place cut, a new joint with a pipe section, and then pick up

- Q: Well, one day, due to lack of excitement in my day, I decided to go on a little computer exploration adventure.I went to Control Panel System Hardware Device Manager Device Manager.However, once I clicked &Device Manager,& I was restricted from accessing &mmc.exe.&So what is this &mmc.exe&/&Device Manager,& and what does it do?

- obviously you don't know what you are doing so call someone who does,,, you can end up burning your house down,,,,and no the horns may not work with just any system,, depends on the voltages used!! and learn english,, there is no such thing as : has went off

- Q: What is a slot type mechanical joint?Copy search

- The utility model relates to a groove connecting pipe which has the function of sealing and sealing, and mainly comprises three parts: a sealing rubber ring, a clamping band and a locking bolt. The inner rubber sealing ring is arranged on the outer side of the connecting pipe and is matched with the pre rolling groove, and then the outer ring is buckled on the rubber ring, and then can be fastened with two bolts.

- Q: In Windows XP the performance of the system is extremely slow down at the long run. How to tune Windows XP?

- Use system restore and back your computer up a day or two

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Taper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords