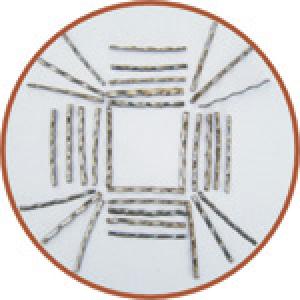

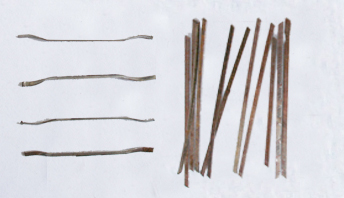

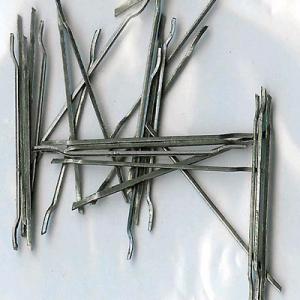

Low Carbon Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Low Carbon Steel Fiber

|

- Q: How is carbon steel different from stainless steel?

- Carbon steel and stainless steel are two distinct types of steel with different properties. The main difference lies in their composition and resistance to corrosion. Carbon steel contains a higher amount of carbon, which gives it strength and durability but makes it prone to rusting. On the other hand, stainless steel is an alloy that contains chromium, which enhances its corrosion resistance. This makes stainless steel less likely to rust or stain, making it suitable for applications where exposure to moisture or corrosive substances is expected.

- Q: What are the applications of steel grating in industrial platforms?

- Steel grating has numerous applications in industrial platforms due to its durability, strength, and versatility. It is commonly used in industrial platforms to provide a safe and reliable flooring solution. Steel grating enhances worker safety by offering slip-resistant surfaces, allowing for drainage of liquids and debris, and providing strong support for heavy loads. It is also utilized in mezzanine floors, catwalks, walkways, and stair treads, allowing for easy access and movement within industrial facilities. Additionally, steel grating can be customized to meet specific requirements, making it an ideal choice for various industrial platforms.

- Q: How is steel used in the manufacturing of appliances?

- Steel is commonly used in the manufacturing of appliances due to its high strength, durability, and heat resistance. It is used to construct the outer shells and frames of appliances such as refrigerators, ovens, and washing machines, providing a sturdy and long-lasting structure. Steel is also used in the internal components of appliances, including motors, heating elements, and various mechanical parts, ensuring their efficient and reliable operation.

- Q: What are the different types of steel beams used in building structures?

- There are several types of steel beams commonly used in building structures, including I-beams, H-beams, and wide flange beams. I-beams, also known as W-beams, have a cross-section shaped like the letter "I" and are commonly used in residential and commercial construction. H-beams, also known as H-shaped beams, have a cross-section shaped like the letter "H" and are often used in bridge construction. Wide flange beams, also known as W-flange beams, have a wider flange than I-beams and are commonly used in industrial and commercial construction.

- Q: What is the role of steel in the manufacturing of furniture?

- Steel plays a crucial role in the manufacturing of furniture due to its strength, durability, and versatility. It is commonly used in the construction of the frame and structure of furniture pieces, providing stability and support. Steel can be formed into various shapes and sizes, allowing for creative and intricate designs. Additionally, it can be coated or finished in different ways to enhance its appearance and protect it from wear and tear. Overall, steel enhances the overall quality and longevity of furniture, making it an essential material in the manufacturing process.

- Q: How is steel used in the construction of sports facilities?

- Steel is commonly used in the construction of sports facilities due to its strength and durability. It is used to create the framework of the structures, such as the supports for roofs and walls. Steel is also used in the construction of bleachers, seating areas, and staircases. Its versatility allows for the creation of large, open spaces, ensuring the safety and comfort of spectators. Additionally, steel's resistance to corrosion makes it suitable for outdoor sports facilities, as it can withstand harsh weather conditions.

- Q: What are the different grades of steel used in various industries?

- There are several different grades of steel used in various industries, each with its own unique properties and characteristics. Some common grades include carbon steel, stainless steel, alloy steel, and tool steel. Carbon steel is widely used due to its strength and affordability, while stainless steel is corrosion-resistant and often used in the food and medical industries. Alloy steel is known for its high strength and durability, making it suitable for construction and automotive applications. Tool steel is specifically designed to withstand high temperatures and pressures, making it ideal for cutting and shaping tools.

- Q: How is steel used in the transportation industry?

- Steel is used in the transportation industry for various purposes, such as constructing the body and chassis of vehicles, manufacturing rail tracks, and producing infrastructure for bridges and tunnels. Its strength, durability, and ability to withstand high pressures and impacts make it an ideal material for ensuring the safety and reliability of transportation systems.

- Q: What are the common uses of steel in everyday life?

- Steel is widely used in everyday life for various purposes. It is commonly used in the construction industry for buildings, bridges, and infrastructure due to its strength and durability. Steel is also used in the manufacturing of automobiles, appliances, and machinery, as it provides the necessary strength and rigidity. Additionally, steel is used in the production of household items such as cutlery, utensils, and tools. Its versatility and reliability make it an essential material in numerous applications, making our lives more convenient and efficient.

- Q: How is steel plate produced?

- Steel plate is produced through a process called steelmaking, which involves melting iron ore in a blast furnace and adding various alloys to achieve the desired properties. The molten steel is then poured into a casting machine to form a slab, which is further processed through rolling mills to reduce its thickness and improve its surface finish. This process results in the production of steel plate, which can be used in various industries for construction, manufacturing, and infrastructure projects.

Send your message to us

Low Carbon Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords