High Speed Soft/Tight Bobbin Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

High Speed Soft/Tight Bobbin Winding Machine is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

High Speed Soft/Tight Bobbin Winding Machine

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

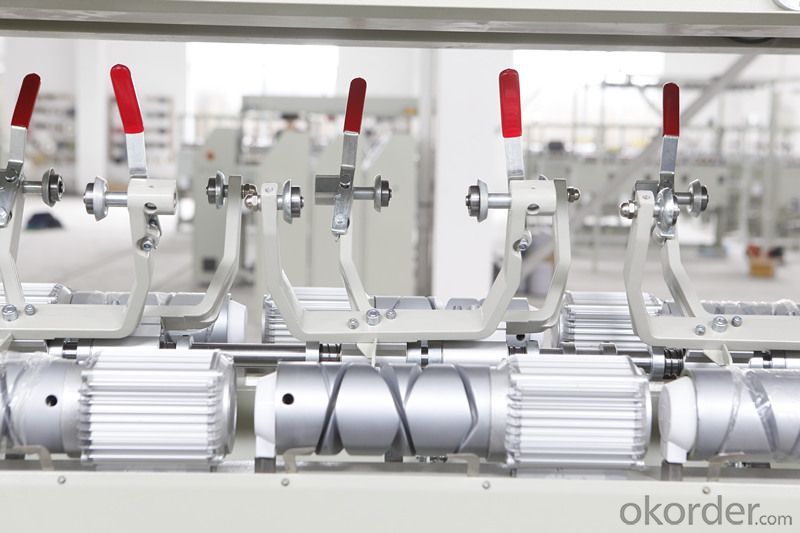

Product pictures of High Speed Soft/Tight Bobbin Winding Machine:

Delivery Pictures:

Specification:

High Speed Soft/Tight Bobbin Winding Machine

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of High Speed Soft/Tight Bobbin Winding Machine:

· Q:What is the machine used for?

A: High-speed Soft Bobbin Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- Since the invention of the shuttle, people have been committed to the development of new textile machinery, unfortunately, progress has been unhappy. The gift of science is prepared for those who are prepared.

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- The domestic basic industry is weak, the basic parts can not keep up, affecting the quality of textile machinery products and mechanical and electrical integration level. Textile machinery product development and the lack of organic cooperation, affecting the use of textile products effect. Policy does not match, affecting the competitiveness of domestic textile machinery products. In view of these problems, China's textile industry has adopted a series of measures to vigorously develop the basic equipment of textile machinery, the introduction of foreign textile machinery technology, differentiated development strategy, and the introduction of the corresponding policy of supporting the development of textile machinery, and achieved good results The

- Q: What is the current status of the textile industry?

- China's textile enterprises should overcome the difficulties of rising raw materials, appreciation of the renminbi and export tax rebates, seize the opportunities for the development of the textile industry, improve the concentration of the industry, curb the blind expansion of inefficient production capacity, increase the construction of special industrial parks, strengthen independent innovation The pace of China's textile industry to enhance the brand building, industrial restructuring and upgrading. So that China by the textile power to the textile power forward.

- Q: When the textile industry, as well as the history of the textile industry development?

- Silk is the most excellent, longest and finest textile fiber in all natural fibers and can be woven in a variety of complex pattern jacquard fabrics. The extensive use of silk fiber, greatly promoted the ancient Chinese textile technology and textile machinery progress, so that silk production technology in ancient China to become the most unique and representative of the textile technology.

- Q: Textile equipment to protect the work is not a special type of work?

- First, the original State Administration of Labor "on the textile industry chemical fiber (viscose) toxic and hazardous operations early retirement job of the reply (81) Laojue Zi word 36) document, the following 13 types of toxic and hazardous special types of work: Carbon disulfide manufacturing, calcium sulphate liquid preparation workers, diggers, detergents, bleach, sulfonation, plate and frame filter workers, spinning workers, filament twist yarn and silk workers, filament head workers, filament Silk workers, cellophane manufacturing workers, iron chromium salt manufacturing workers.

- Q: Is there a textile industry in the Qin Dynasty?

- Han labor people is the first invention and mass production of silk use of the nation, the production of silk products is to open the world's first large-scale East-West trade exchanges, known as the "Silk Road."

- Q: Is the textile machine made of those accessories?

- There is no concept of spinning machine, spinning and weaving are separate, and spinning and weaving process is very long, do not want you to imagine only one or two equipment can be, the entire production process involved in the equipment up to a dozen

- Q: What is the task of preparing the process before spinning?

- The pressed raw cotton was loosened to about 0.1 mg of cotton

- Q: What modern textile machinery?

- One is to make the whole machine. The other is the manufacture of special spare parts (such as spindle, cradle, steel collar, bead ring, knitting needle, needle cloth, heddle, stop sheet, etc.).

- Q: What is a pedal loom?

- According to the historical records contained in the history books, the number of fabrics donated between the princes of the Warring States Period was higher than that of the spring and autumn. In recent years, the figures of the Han Dynasty, such as the Han Dynasty stone carvings, Appear dating back to the Warring States period

Send your message to us

High Speed Soft/Tight Bobbin Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords