Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application:

Soft/Tight Fibre Cone Textile Winding Machine is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

Soft/Tight Fibre Cone Textile Winding Machine

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

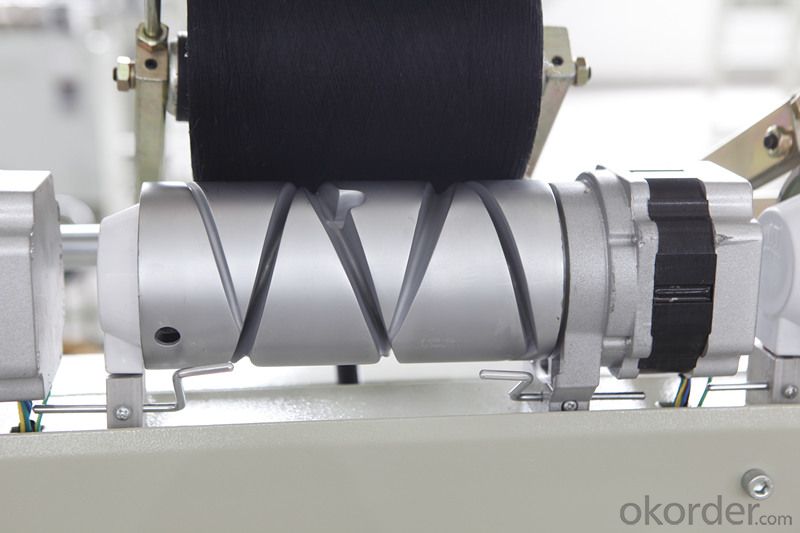

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

Product pictures of Soft/Tight Fibre Cone Textile Winding Machine:

Delivery Pictures:

Specification:

Soft/Tight Fibre Cone Textile Winding Machine

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of Soft/Tight Fibre Cone Textile Winding Machine:

· Q:What is the machine used for?

A: Soft/Tight Fibre Cone Textile Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is spinning down?

- Even in the twentieth century, some nomadic Tibetans in Tibet were still spinning it.

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- The domestic basic industry is weak, the basic parts can not keep up, affecting the quality of textile machinery products and mechanical and electrical integration level. Textile machinery product development and the lack of organic cooperation, affecting the use of textile products effect. Policy does not match, affecting the competitiveness of domestic textile machinery products. In view of these problems, China's textile industry has adopted a series of measures to vigorously develop the basic equipment of textile machinery, the introduction of foreign textile machinery technology, differentiated development strategy, and the introduction of the corresponding policy of supporting the development of textile machinery, and achieved good results The

- Q: What is a large hydraulic spinning wheel?

- Song and Yuan Dynasties, with the socio-economic development, in a variety of transmission machine on the basis of spinning, and gradually produced a dozens of spindle spindle

- Q: What is the current status of the textile industry?

- From the international environment, the international market is still a large expansion of space and opportunities. With the end of 2007, China and the EU textile limit expires, the end of 2008 the end of the Sino-US textile quota limit, the Chinese textile quota era is approaching, accounting for more than 60% of the global textile market share area is fully open, will bring to China's textile trade Great opportunity. And the next few years the world economy will remain in the rising range, will promote the growth of international trade, which will give China's textile and garment exports to bring favorable international market protection.

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient countries in the world for the textile fibers are natural fibers, usually wool, linen, cotton) three short fibers, such as the Mediterranean region before the textile fiber is only wool and linen; India Peninsula region before the use of cotton

- Q: When did Chinese ancient textile technology come from? Why does Europe call China "silk country"?

- Indicating that more than 3400 years ago, our people have mastered the bark fiber degumming technology. These linen textile level has been equivalent to more than a thousand years after the Western Han Dynasty maw heap of the tomb of linen

- Q: What is the current domestic textile enterprises?

- Boshi Group Co., Ltd., Lutai Group, Inner Mongolia Ordos Cashmere Group Co., Ltd. Bosideng Co., Ltd., Lutai Group, Inner Mongolia Ordos Cashmere Group Co., Ltd.

- Q: What is the chenille mechanical principle?

- The chenille spinning machine is also called a new type of spinning equipment for the production and processing of chenille yarn

- Q: What are the classification of textile machinery?

- 2. Spinning wheel

Send your message to us

Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords