High Speed Vertical Soft Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

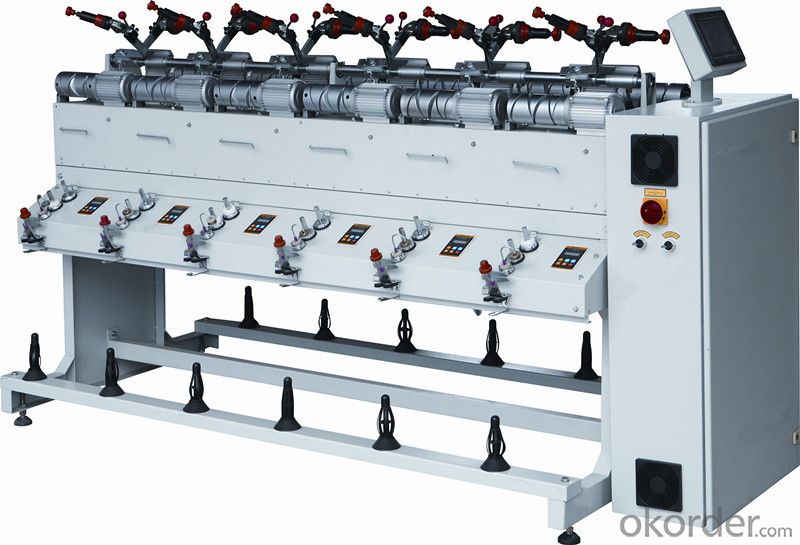

Description of High Speed Vertical Soft Winding Machine:

High Speed Vertical Soft Winding Machine is used for winding yarns on cones.

Main Features:

High Speed Vertical Soft Winding Machine has the following advantages:

· High precision, highly polished, self-lubricating on surface, litter friction with yarn are our basic functions.

· Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

· High-tech in dealing with surface, and it makes our grooved drums have high wear resistance, corrosion resistance and makes sure the hardness of the groove and surface are the same.

Good forming and uniform linear density.

· Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

· Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

Images of High Speed Vertical Soft Winding Machine:

Package & Shipping Pictures:

Specification:

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

| Package shape | Cylindrical or conical packages |

| Traverse length | 147mm,150mm,154mm |

| External dimensions | 13410mm(length) ×700mm(width) ×1680mm(height) |

| Power supply | 3 phased 380V±10% ,50/60HZ |

| Automatic length fixing | Automatic length fixing,max:999999m |

FAQ of High Speed Vertical Soft Winding Machine:

· Q:What is the machine used for?

A:High Speed Vertical Soft Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is a spinning wheel?

- While the pedal spinning wheel drive the power of the spinning wheel from the foot, the operation, the spinning woman can use both hands for spinning operation, greatly improving the work efficiency. Since its inception, spinning gear has been the most popular spinning machine, even in modern times, some remote areas still use it as the main spinning tool.

- Q: What is the second-hand textile machinery import clearance process?

- 1. Used equipment, but to maintain its basic use value or the full use value

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- 2008-2010, with the rapid development of the world and China's textile industry, the demand for textile machinery more and more, China's textile industry development is facing a good opportunity. It is expected that by 2010, by the promotion of textile machinery, China's textile machinery industry, the new product output value will be increased from 25% in 2005 to 50%

- Q: What are the general fixed assets of the textile industry?

- Cord wire spinning machine, nylon filament spinning machine, other polyester, nylon equipment, polypropylene equipment, cellulose fiber equipment

- Q: What is the current status of the textile industry?

- From the domestic economic environment, domestic demand will become an important driving force for industry growth. About 80% of Chinese textiles in the domestic consumption. With the sustained and rapid growth of the domestic economy, the stability of residents' income will boost the further development of the domestic market.

- Q: What is the current domestic textile enterprises?

- Hengli Group Co., Ltd., Shandong Ruyi Technology Group Co., Ltd., Ningbo Shenzhou Knitting Co., Ltd.

- Q: What is the chenille mechanical principle?

- The machine's domestic model is in the digestion and absorption of foreign exhibitors on the basis of the prototype, after the transplant, redesigned and manufactured

- Q: Textile machinery points which six categories? What is the main role?

- Textile machinery is the natural fiber or chemical fiber processing into textiles required by the various mechanical equipment collectively

- Q: What is the task of preparing the process before spinning?

- The various grades of raw cotton were evenly mixed, made of uniform cotton

- Q: What are the classification of textile machinery?

- 3. Hydraulic large spinning wheel

Send your message to us

High Speed Vertical Soft Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords