High Refractoriness Magnesite Alumina Spinel Bricks with Magnesia Hercynite Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Magnesia Hercynite Composite Bricks High Refractoriness

Brief discription for high aluminium bricks

CMAX Magnesia-Hercynite Composite Bricks are made by using high quality raw materials, optimized size grading, enforced homogenization, high pressure forming and firing with clean fuel.

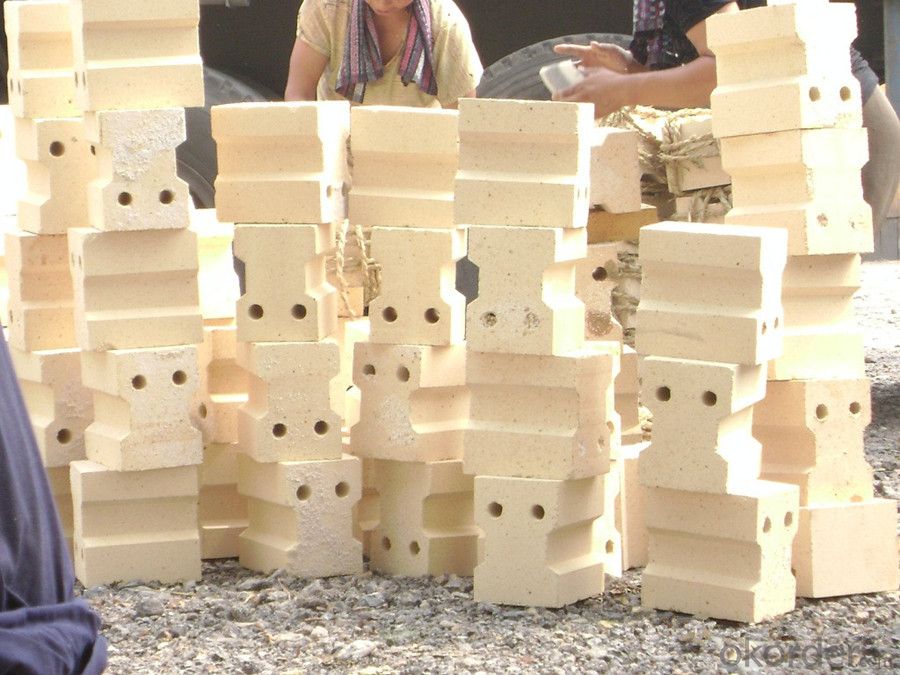

CMAX Magnesia-Hercynite Composite Bricks are mainly used in burning zone, transitional zone of rotary kiln etc.

Advantage for magnesia hercynite composite bricks

◆High refractoriness under load

◆High mechanical strength

◆Excellent thermal shock resistance

◆Corrosion resistance

Technical data for magnesia hercynite composite bricks

ITEM | MA-85A | MA-85B | MA-85C | MA-93A | MA-93B |

MgO,% ≥ | 85 | 82 | 80 | 93 | 90 |

Al2O3,% ≥ | 8 | 8 | 8 | 5 | 5 |

SiO2,% ≤ | 1 | 2 | 3 | 1 | 2 |

Apparent Porosity,% ≤ | 18 | 18 | 19 | 18 | 18 |

Bulk Density, g/cm3 ≥ | 2.95 | 2.9 | 2.85 | 2.95 | 2.9 |

Cold Crushing Strength, Mpa ≥ | 50 | 45 | 40 | 45 | 40 |

Refractoriness Under Load, ℃ ≥ | 1700 | 1700 | 1650 | 1700 | 1700 |

Thermal Shock Resistance< 950℃-Air Quenching, Cycle, ≥ | 120 | 100 | 100 | 100 | 80 |

Thermal Expansion, 1400℃, % | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 |

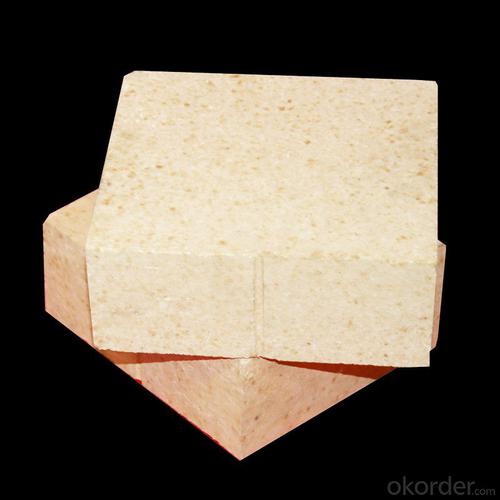

Images/photographs for magnesia hercynite composite bricks

◆ Packaging for magnesia hercynite composite bricks

◆ Producing Equipment for magnesia hercynite composite bricks

◆ Testing Mashines for magnesia hercynite composite bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What are the uses of magnesia spinel brick in the industry?

- Instead of magnesia chrome brick sand manufacturing magnesia spinel brick used in cement kiln, not only to avoid the chrome pollution, but also has good resistance to spalling;

- Q: Spinel refractory brick air-cooled razheng times

- The ingredients are magnesium, aluminum, oxygen.

- Q: Is magnesium spinel harmful to the body? Such as title magnesium spinel, harmful to the body?

- The long-term intake of aluminum will eventually harm the health of the human body. These two elements are not soluble and can cause pneumoconiosis and lung cancer after inhalation.

- Q: What's the difference between iron spinel and magnesium aluminum spinel?

- Such as aluminum spinel, iron spinel, zinc spinel, manganese spinel, chromium spinel, etc.. Due to the inclusion of different elements, different spinel can have different colors, such as magnesium spinel in red, blue, green, brown or colorless between; zinc spinel is dark green; iron spinel black, and so on.

- Q: Spinel compound brick composite layer pollution layer does not affect the use of theoretical basis for it

- One is the development of the manufacturing process of the magnesia magnesia purity can be improved, with low content of magnesia silicate phase has good resistance to spalling, does not require the addition of alumina can also produce good thermal shock stability is of high quality magnesia brick; two foreign chromite resources is abundant, magnesia chrome refractories production has thermal stability good and anti erosion ability.

- Q: What are the characteristics of Mg rich spinel and aluminium rich spinel?

- Magnesium spinel is a subspecies of spinel, which is MgAl2O4, also called spinel. An equiaxed crystal having eight crystalline or irregularly granular crystals.

- Q: What is the high-grade magnesia spinel brick?

- Using magnesia as main raw materials, matrix co milling with magnesia and bauxite as alkaline products, high temperature burning, called magnesia brick, also called the first generation of periclase spinel brick.

- Q: What is the structure of magnesium aluminate spinel?

- The crystal is composed of eight faces, eight bodies and twelve faces of diamond

- Q: What is the significance of the synthesis of mg Al spinel? What are the main approaches?

- Because the thermal expansion coefficient of magnesia alumina spinel is small, the thermal shock resistance of refractory products with its bonding phase is relatively improved.

- Q: Characteristics of sintered spinel used in refractory zzjsnc

- For the production of castable for ladle lining steel plate greatly improve the anti erosion ability. It is widely used in steelmaking refractories provides new raw material for the production of high quality synthetic stone pre sintered spinel prepared amorphous and amorphous high purity refractory material

Send your message to us

High Refractoriness Magnesite Alumina Spinel Bricks with Magnesia Hercynite Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords