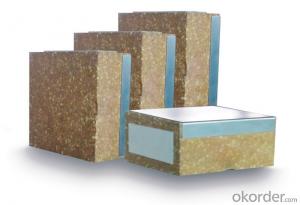

High Quality Corundum Magnesia Aluminate Spinel Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications

Mainly used for ladle lining and bottom .

Typical Features

It can realize ladle low carbon and carbon-free to meet the needs of high grade and ultra-clean steel. The products are characterized by corrosion resistance, penetration resistance, erosion resistance, spalling resistance and good integrity, to meet the need of complete refining ladle.

Specifications

| Brand | GYT-1 | GYT-2 |

| MgO % | 3-6 | 3-6 |

| Al2O3 % | ≥ 90 | ≥ 90 |

| C % | 1-3 | 1-3 |

| Apparent porosity %, ≤ | 12 | 12 |

| Bulk density g/cm3, ≥ | 3.2 | 3.2 |

| Crushing strength Mpa, ≥ | 40 | 40 |

| Linear change rate (1550°C) % | -0.5~+1.5 | -0.5~+1.5 |

Quick Details

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Al203, MgO, C |

| Al2O3 Content (%): | min 90 | MgO Content (%): | min 3-6 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° |

| Brand Name: | CNBM | Bulk density,g/cm3: | min 3.2 | Application: | used for ladle lining and bottom |

| Crushing strength/Mpa: | min 40-45 | Payment: | LC,TT,DP,West Union | C%: | 0-3 |

| Apparent porosity%: | max 12 | Linear change rate%: | -0.5~+1.5 |

Packaging & Delivery

| Packaging Details: | based on the quantity you required |

| Delivery Detail: | based on the quantity you required |

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the workpiece, choose the appropriate hardware castable, corundum brick or refractory bricks, etc.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- The fused zirconia corundum brick is made up of 30% ~ 41% zirconia two in the alumina burden. The main mineral compositions are corundum, zircon and glass phase. The main varieties are fused (or cast) zirconium corundum brick (also known as AZS casting brick) and sintered zirconia corundum brick. Generally speaking, zircon corundum brick means sintered zirconia corundum brick. It is made from alpha -Al2O3, partially stabilized zirconia and zircon corundum clinker, which is prepared by proportioning and molding at 1700~1750 DEG C and then sintered at two. The sintered zirconium corundum brick has a strong resistance to molten glass, and its thermal shock resistance is stronger than that of fused zirconia corundum brick. It is mainly used as lining of glass furnace and induction furnace, as well as steel rolling furnace, slide rail, etc..

- Q: Ask for help about the phase of refractory material

- Secondary crystalline phase. The second phase and second phase or second phase, and the main crystal phase and is in high temperature liquid phase coexistence in refractory material, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase. There are structure of refractory refractory material in the crystal phase, especially the direct combination of high melting point and so on, the resistance to high temperature also tend to benefit. Compared with the ordinary brick, the second phase of the refractory products, make the products refractoriness under load are improved. Many according to mineral composition of refractory material named, such as mullite corundum brick, corundum mullite brick, is its main crystal phase and the second phase composite named. The former is mainly crystal phase, the latter is sub crystalline phase.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q: What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

Send your message to us

High Quality Corundum Magnesia Aluminate Spinel Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords