High Alumina Magnesia-MA Spinel Bricks with High Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Magnesia-ma Spinel Bricks High Mechanical Strength

Brief discription for magnesia-ma spinel bricks

CMAX magnesia-ma spinel bricks are made by using high quality raw materials, optimized size grading, enforced homogenization, high pressure forming and firing with clean fuel.

CMAX magnesia-ma spinel bricks are mainly used in burning zone, transitional zone of rotary kiln etc.

Advantage for magnesia-ma spinel bricks

◆High refractoriness under load

◆High mechanical strength

◆Excellent thermal shock resistance

◆Corrosion resistance

Technical data for magnesia-ma spinel bricks

ITEM | MA-85A | MA-85B | MA-85C | MA-93A | MA-93B |

MgO,% ≥ | 85 | 82 | 80 | 93 | 90 |

Al2O3,% ≥ | 8 | 8 | 8 | 5 | 5 |

SiO2,% ≤ | 1 | 2 | 3 | 1 | 2 |

Apparent Porosity,% ≤ | 18 | 18 | 19 | 18 | 18 |

Bulk Density, g/cm3 ≥ | 2.95 | 2.9 | 2.85 | 2.95 | 2.9 |

Cold Crushing Strength, Mpa ≥ | 50 | 45 | 40 | 45 | 40 |

Refractoriness Under Load, ℃ ≥ | 1700 | 1700 | 1650 | 1700 | 1700 |

Thermal Shock Resistance< 950℃-Air Quenching, Cycle, ≥ | 120 | 100 | 100 | 100 | 80 |

Thermal Expansion, 1400℃, % | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 |

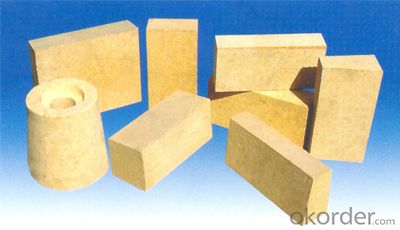

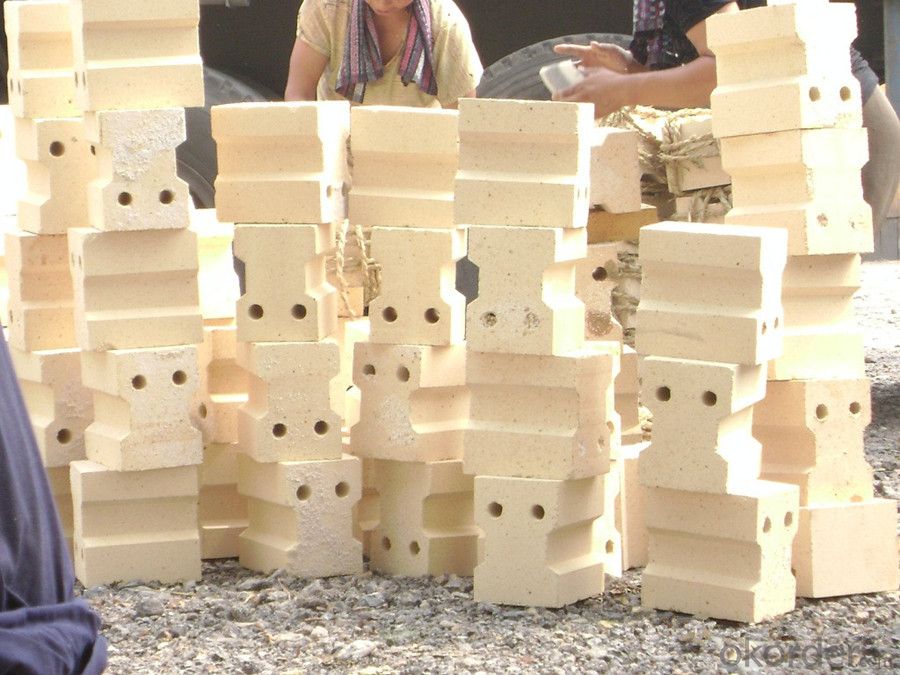

Images/photographs for magnesia-ma spinel bricks

◆ Packaging for Magnesia-ma Spinel Bricks

◆ Producing Equipment for Magnesia-ma Spinel Bricks

◆ Testing Mashines for Magnesia-ma Spinel Bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What are the high aluminum bricks made of?

- We specialize in the production of various LeiBao refractory refractory material, such as corundum, zirconia products, alumina hollow ball products, mullite products and so on.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: What are the characteristics of high alumina bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred.

Send your message to us

High Alumina Magnesia-MA Spinel Bricks with High Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords