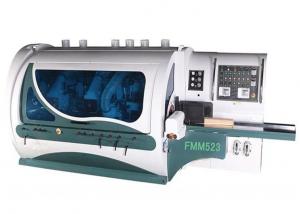

CNC Router For Woodworking

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of CNC Router for woodworking:

1, Cast Steel for the support of the gantry, analyzing and designing by FEA, stationary working table

2, Thick steel gantry, fixed gantry makes sure the structure endures a much longer time.

3, The bed lathe is connected by the ball screw , more precise and stable.

4, Eight spindles, air cooled, higher efficient.

5, Air balance cylinders, make sure the Z axis move smoothly and correctly.

6, Servo motors transmission, higher speed and more precise could work still well after hours.

7, Higher speed, during work, could up to 15m/min

8, 8axis, could do 8 axis work perfectly.

Technical parameters of CNC Router for woodworking:

Performance Parameters | ||

Name | CNBM-ATC (1300*2500*280 mm) | |

Transmission | Taiwan Square rail HIWIN ( x/z 25; Y 30) ;Germany ball screw | |

Max Moving Speed | 60000mm/min | |

Max Engraving Speed | 25000mm/min | |

Reposition | < 0.04mm/300mm | |

Motor | Japan YASKAWA Servo Motor | |

Conventor | Taiwan Delt brand | |

Transformer | SANO intelligent servo transformer | |

Spindle Motor | Italy HSD9.0KW ATC air cooling spindle | |

Spindle speed | 6000-24000rpm | |

Table | vacuum /clamp double use function | |

Control System | Taiwan Syntec control system | |

Compatible software | Artcam/TYP3/CASTMATE/Wentai/CAD/CAM/Hpgl | |

Tool diameter | ¢3.175 / ¢6 / ¢12.7mm | |

Tools | Rotary carousel,8 tools | |

Voltage |

| AC380V/50Hz |

Warranty | One year | |

Training | Free | |

Power Supply Requirement. | AC380V/50Hz. | |

Dust collector and vacuum pump | The two is optional, if need , add 400$. | |

Factory information of CNC Router for woodworking:

Components of CNC Router for woodworking:

- Q: Please hand woodworking planer, the wooden part is what species?

- The commonly used woodworking planer with woodSouth oak wood is dark red, more commonly used materials, high-grade general cargo container frame. Relatively heavy.The Japanese side oak, orange red, is the ideal material.

- Q: A woodworking plane planer installation angle is?

- In the cutter spindle mounted at 30 degrees angle, blade angle in 20 planes to 45 degrees, see materials and planing speed to increase or decrease by cutting edge strengthening processing tool, its service life can be increased by 70%. The better wear resistance of cutting tools.

- Q: I have a woodworking planer, the hardness is not enough, how can we strengthen the hardness of it

- Because you have to first find out the cutter material, according to the material selection process suitable for heat treatment, the method of equipment and experience is not made by amateurs. Just to use words suggest replacing other planes.

- Q: How to wear woodworking planer grinding sharper?

- Explain the grindstone grindstone (double side side coarse fine) hold the knife down, with a grindstone opposite rough planer knife into section 40 degrees, parallel to pull back and forth (planer and stone 30);

- Q: Who knows the installation method of woodworking planer?

- The weight is bent, the installation is installed in the plane above the rail pressure, inner surface on the planer tool, thread is in pressure prominent iron outer bending surface, does not affect the use of theTake a closer look at the picture below

- Q: A woodworking plane how to adjust the use of methods and skills?

- A lying nine, not pushed; Li Wo eight, labor in vain: This refers to the slope in the planer cutter. When the vertical direction is one inch, the horizontal direction of nine points, equivalent angle is 49 degrees, suitable for cutting hard wood, push to dig more lively, general construction site use red pine, cork more, with a lying on a slope, the equivalent angle of 45 DEG C. If the use of standing down eight slope, it will be more difficult to use. Of course, in addition to some special purpose planing, planing slope also need appropriate changes, such as pull planing, slotting plane slope will be smaller; grooving, line planing, slope should be appropriate to increase a little.

- Q: Woodworking planer hard alloy cutter to welding

- 1. according to the woodworking planer hard alloy blade shape and tool geometric parameters of blade with groove shape;2., check the blade supporting surface can not have serious bending, carbide tool welding surface shall not have serious carburized layer, at the same time should also carbide tools, blade surface and knife rod groove in the dirt removal.

- Q: What tools are needed for interior door mounting carpenters?

- A woodworking implement, as of wood. Generally have a sharp edge, and must pay attention to safety when using. Need regular grinding, especially knives, chisels, should be sharpened, in order to use the advantages of labor saving, and ensure the quality, the so-called "modaobuwukanchaigong" is the truth.

- Q: How many degrees of ability of woodworking machinery cutter grinding durable

- And you processed wood hardness, generally at 45 degrees, the harder the angle, the more sharp, easy to corner. If it is an alloy knife, it must be greater than 45 degrees because the alloy knife is not shock resistant.

- Q: What brand of carbide woodworking planer good quality?

- Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

CNC Router For Woodworking

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords