High quality white organic bentonite clay powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg/m²

- Supply Capability:

- 10000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

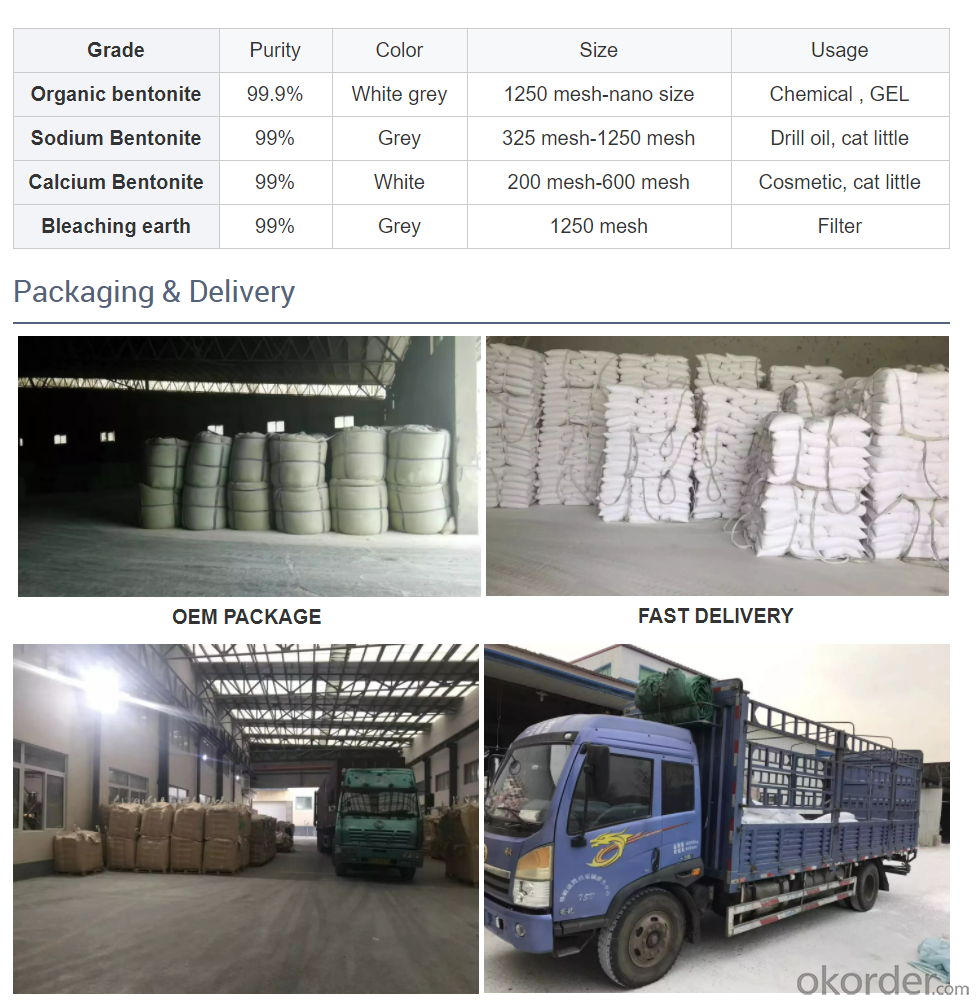

Specification

High quality white organic bentonite clay powder

Bentonite is a clay generated frequently from the alteration of volcanic ash, consisting predominantly of smectite minerals, usually montmorillonite. Other smectite group minerals include hectorite, saponite, beidelite and nontronite. Smectites are clay minerals, i.e. they consist of individual crystallites the majority of which are<2µm in largest dimension.

The extent of hydration produces intercrystalline swelling. Depending on the nature of their genesis, bentonites contain a variety of accessory minerals in addition to montmorillonite. These minerals may include quartz, feldspar, calcite and gypsum. The presence of these minerals can impact the industrial value of a deposit, reducing or increasing its value depending on the application.

Main Applications :

Agriculture and Animal Feeds

Asphalt Emulsifiers

Ceramics

Construction and Civil Engineering

Detergents

Environmental Sealants

Horizontal Drilling

Household Cleaners

Industrial Coatings

Iron Ore Pelletizing

Metal Casting

Oils/Food Processing

Oil and Gas Drilling

Paints, Dyes and Polishes

Papermaking and Paper Recycling

Pet Products

Pharmaceuticals, Cosmetics and Medicine

Wastewater Treatment

Wine and Juice Clarification

Bentonite is used as thickening agent and anti-settling agent for paint inks

Company profile

Our company has a very advantageous geographical position in mining and export. The company has a very professional production team and is committed to providing high-quality products and services. We not only have professional R & D personnel, but also a professional sales team. Since its establishment. Relying on sincere attitude, advanced equipment, exquisite technology, excellent products and reliable service, the company has attracted a large number of customers at home and abroad. Due to our emphasis on quality, credibility and abiding by the contract, we have won unanimous praise fromdomestic and foreign customers.

- Q: What's the stability of rare earth calcium zinc stabilizer? What are the advantages?

- The dispersion and anti decomposition properties of rare earth calcium zinc stabilizer are better than that of lead salt stabilizer, and the color, brightness and firmness of the product are improved. Besides, the defects that lead salts are easy to generate sulfuration pollution are avoided.

- Q: Method for processing rare earth ore

- Warehouse workshop of water: commonly known as the boiler room, this should be a soft water, which is distilled water, in particular in production of this water, because there is no mixed material here.

- Q: What's the use of rare earth? Why Japan wants to buy Chinese rare earth?

- Rare earth ferrosilicon alloy, rare earth silicon magnesium alloy as spheroidizing agent in the production of rare earth nodular cast iron, ductile cast iron, because this is particularly suitable for the production of the special requirements of the complex ductile iron, are widely used in automobile, tractor, diesel engine and other mechanical manufacturing; rare earth metals added to magnesium, aluminum, copper, zinc, nickel, etc. non-ferrous alloys, physical and chemical properties of the alloys can be improved, and improve the mechanical properties of alloy at room temperature and high temperature. Made of rare earth molecular sieve catalyst in petroleum chemical industry, has the advantages of high activity, good selectivity and strong resistance to heavy metal poisoning, which replaces the aluminum silicate catalyst used in petroleum catalytic cracking process; in ammonia production process, with a small amount of rare earth nitrate as catalyst, its treatment capacity than Ni Al catalyst 1.5 times; in cis-1,4-polybutadiene rubber and isoprene rubber in the process of using naphthenic acid rare earth aluminum products three kinds of catalyst, the obtained performance is excellent, with less equipment fubberized, stable operation, postprocessing the advantages of short process; composite rare earth oxides can also be used as an internal combustion engine exhaust purification catalysts, cerium naphthenate also can be used as paint drying agent.

- Q: What is the difference between a multicomponent alloy and a rare earth alloy?

- Raw aluminum impurities many, very brittle, a knock on the broken. Aluminum is often recycled aluminum, aluminum pot, the broken broken aluminum spoon collected by re melting.

- Q: What's the use of rare earth?

- Rare earth materials are used as the key to many major weapons systems, it is also a lot of sophisticated industrial essential raw materials, rare earth elements have electric, magnetic, optical, biological and other properties, is an important basic material information technology, biological technology, energy technology and other high technology fields and national defense construction, at the same time on the transformation of some traditional industries, such as agriculture, chemical industry, building materials and other plays an important role

- Q: Rare earth in the end what to do ah?

- Military: because of its excellent photoelectric magnetic and other physical properties, and other materials composed of new materials, the performance of different varieties, the most obvious function is to greatly improve the quality and performance of other products. For example, the tactical performance of steels, aluminum alloys, magnesium alloys and titanium alloys for tanks, aircraft and missiles has been greatly improved. What's more, rare earth is also a high-tech lubricant for electronics, lasers, nuclear industry, superconductivity, and so on.Metallurgical Industry: rare earth metal silicide or fluoride, added to steel, to refining, desulfurization, and low melting point of harmful impurities, and can improve the processing performance of steel; rare earth ferrosilicon alloy, rare earth silicon magnesium alloy as spheroidizing agent in the production of rare earth nodular cast iron, ductile cast iron, because this is particularly suitable for the production of the special requirements of the complex ductile iron, are widely used in automobile, tractor, diesel engine and other mechanical manufacturing; rare earth metals added to magnesium, aluminum, copper, zinc, nickel and other non-ferrous alloys, physical and chemical properties of the alloys can be improved, and improve the mechanical properties of alloy at room temperature and high temperature.

- Q: Use of rare earth? Which industries depend on him?

- The catalyst with molecular sieve made of rare earth, has the advantages of high activity, good selectivity and strong resistance to heavy metal poisoning, which replaces the aluminum silicate catalyst used in petroleum catalytic cracking process; in ammonia production process, with a small amount of rare earth nitrate as catalyst, the gas volume is 1.5 times bigger than in Ni Al catalyst; synthesis of isoprene rubber and butadiene rubber in the process of using naphthenic acid rare earth aluminum products three kinds of catalyst, the obtained performance is excellent, with less equipment fubberized, stable operation, postprocessing the advantages of short process; composite rare earth oxides can also be used as an internal combustion engine exhaust purification catalysts, cerium naphthenate is also used as a paint drier etc..

- Q: Pink and what is the difference between rare earth polishing powder

- More than 10 kinds of metal oxides, such as aluminum, zinc, chromium, manganese, titanium, zirconium, silicon, iron and rare earth, have been used in industry.In the polishing powder polishing effect of cerium based polishing powder is best, it has been replaced by other polishing powder (such as SiO2, ZrO2 and Fe2O3) applications, so there will be a cerium based rare earth polishing powder, known as the "king of polishing powder".

- Q: Why should China export rare earths at a low price?

- Rare earth has always been a national strategic resource, and is regarded as the key to the future world.While China's Baiyunebo rare earth ore accounts for 90% of the world's recoverable resources, and 70% of the world's rare earth consumption is exported to China, so Chinese geologists call rare earth "the only blessing God has for the suffering Chinese."". But because of uncontrolled exploitation, wanton export traitorous comprador, coupled with Japan strategic alliance to keep the prices down, in the rare earth resources in the international market prices even offset back mining cost. This kind of situation, people can not help but burst into tears!

Send your message to us

High quality white organic bentonite clay powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg/m²

- Supply Capability:

- 10000 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches