High Quality Low Carbon Solid Wood Veneers 004

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m, m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon wood

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Specification of low carbon wood

Standard: 3000mm(L)×1200mm(W)×15mm(T)

Standard length: 3000mm

Standard width: 120mm,150mm,200mm,300mm(including 3mm kerf width)

Standard thickness: 15mm

Technical information of low carbon wood

|

Density |

1.26g/m3 |

Folding strength |

10Mpa |

|

Dry-shrinkage rate |

0.05% |

Elastic modulus |

7211Mpa |

|

Wet expansion rate |

0.17% |

Shear strength |

3.5Mpa |

|

Screw holding capability |

121N/mm |

Coefficient of heat conductivity |

0.69(W(m·k)) |

|

Frost resistance |

Thaw-freeze cycle after 30 times, no slip crack and peeling off | ||

|

Unpermeability |

No drop appearing on the bottom after 24 hours. | ||

|

Impact strength |

3.3KJ/m2 | ||

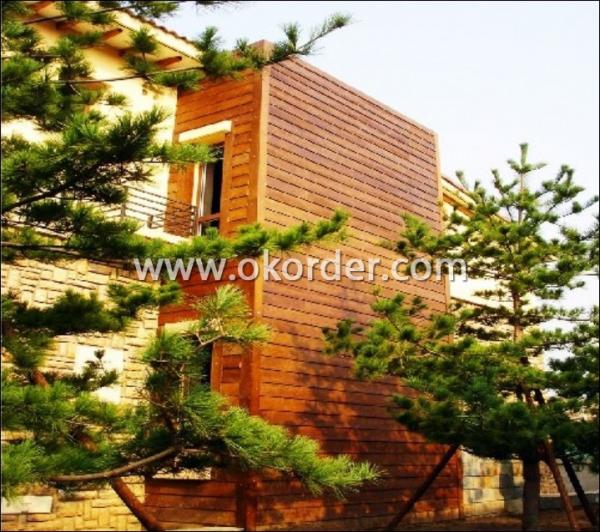

Products exhibition of low carbon wood

Low carbon wood sheets with thin grain

Low carbon wood sheets with thick grain

Project picture of low carbon wood

- Q: Simple construction method of veneer

- . In order to paste the veneer, the optional paint for paint, make it bright or hyperchromic.

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- Let's talk about natural veneer. Natural veneer regardless of pattern or texture than the wood to do the effect of furniture

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- Under normal circumstances, the designer is the use of Wan Nengjiao and white latex, and these two kinds of glue has a great flaw

- Q: Paste veneer craft specifically refers to what

- thus affecting the appearance of furniture, the product quality greatly reduced. In order to solve this technical problem

- Q: Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q: What is the veneer process?

- on the one hand the level of skilled workers Higher, on the other hand the use of low efficiency, longer heating time, and because the viscosity is not strong,

- Q: Technology veneer and natural veneer distinction

- But it has a natural veneer than the advantages. That is not blistering. I think you should understand that. And its pattern of pattern.

- Q: Part of the production process

- The most effective way to improve the plasticity of wood is to adjust both the temperature and the moisture content at the same time to increase the temperature of the wood while increasing the moisture content of the wood.

- Q: The Production process of cooking

- water temperature is best to maintain room temperature, and slowly warming, so as to avoid the thermal stress caused by wood cracking

- Q: Different cutting processes of wood veneer

- in 1965 in Italy and the United Kingdom have launched the earliest, domestic generally called" science and technology.

Send your message to us

High Quality Low Carbon Solid Wood Veneers 004

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m, m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches