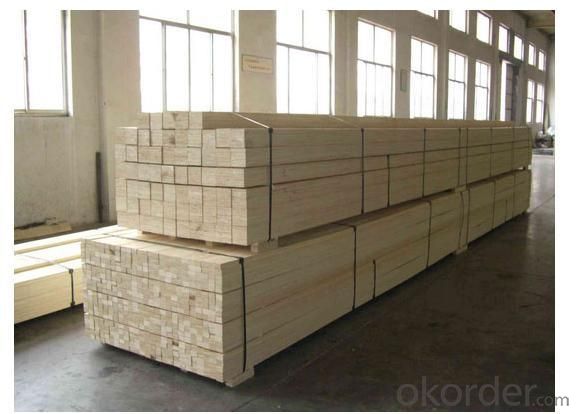

High Quality Laminated Veneer Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The details of the High Quality Laminated Veneer Lumber

|

Standard size |

38/*225*3900 |

|

Core |

pine |

|

Glue |

WBP |

|

Density |

600KG/m³ |

|

Packing details |

57 sheets/pallet,27pallets/40HQ |

Specifications of the High Quality Laminated Veneer Lumber

A) Max Length: 8000mm

B) Thickness: 10-120mm

C) Width: as request

D)Glue: WBP/MR

E) Core: popular/pine/eucalyptus

Features of the High Quality Laminated Veneer Lumber

1) High bending strength

2) Little liner expansion con efficient

3)Strong nail holding

4)Moisture proof and easy work

5)Tight Construction and high Strength

6)No ratten or decay

7)Low formaldehyde emission

The following pictures for your reference.

- Q: Wood products out of the United States is not directly open fumigation can prove that?

- The United States, Canada, Brazil, the Philippines, South Africa, New Zealand, South Korea, Japan, Mexico, Turkey, the European Union, Chile, Australia, Vietnam, Taiwan.

- Q: Species, fruit, flowers, wood and its products

- "the number of representations" is equal to the number of hazards divided by the proportion of the sample; Hazard "level" only fill one, in the corresponding level of "□" in the fight √.

- Q: Wood products export inspection process is what?

- (Hereinafter referred to as: Commodity Inspection Bureau), according to the requirements of the Commodity Inspection Bureau will be sent to the designated fumigation company to do fumigation, generally for the inspection and quarantine of the company, according to the export contract invoice, to the inspection software to declare,

- Q: Wooden Crafts.

- I make an analogy A wooden bead 3000 mesh after sandpaper With white cotton cloth equivalent to 4000 mesh sandpaper Hand equivalent to 5000 mesh sandpaper (dry hand case) White cotton cloth wooden beads after a period of time (Time and wood beads to the original degree of grinding, I was a mirror as a mirror as a standard) To achieve the degree of light Kam mirror can be started after the Just get started when the hand must be used The purpose is to further fine, blocking the brown eye Often, dry hand began, a hand a little bit of sweat, do not be afraid, you can continue to hand Beads feel astringent, and sweat more than the hands of the stop To be a few hours or half a day and then cloth bag half a day Will be like a mirror, then the hand can be used when hand plate This repeated the disk, the natural cytoplasm.

- Q: How to completely remove the stickers on wood products

- 2. Gasoline, 4 yuan more than a liter, a liter can remove a square meter, the disadvantage is strong volatility, large area for a long time will make the paint hair black; 3. Goldfish brand collar net, 3.8 yuan a bottle, the effect is also good, almost no side effects;

- Q: The key to adding the environmental protection flame retardant treatment method

- the process is simple, the disadvantage is to cover the original texture and texture of wood, and Once the protective layer is damaged, its flame retardant properties immediately disappear.

- Q: Introduction The use of resin glue

- The glue in the paste after 30 minutes to reach the maximum strength of 50%, 24 hours after the highest strengt

- Q: Wood furniture products which processes need constant temperature and humidity?

- 4, wood carbonization room or called wood carbonization Shu: for the processing and production of carbonized wood; 5, constant temperature and humidity warehouse or constant temperature and humidity library: for the finished wood products storage. The above five processes are required constant temperature and humidity environment, is a constant temperature and humidity system engineering in the wood products furniture industry applications.

- Q: How to make wood live, wood products can be electrostatic spraying?

- Wood electrostatic spraying need to measure the moisture content of wood, too dry no conductive spray to the effect of poor, and weather and humidity have a certain relationship,

- Q: Wood products waxing

- 1, after waxing will be bright, bright color. Before waxing the best thorough cleaning, keep no dust, no foreign body.

Send your message to us

High Quality Laminated Veneer Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords