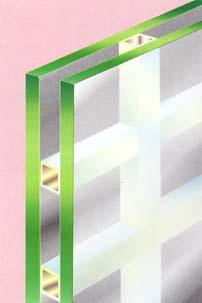

High Quality Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Do material testing (including stone moisture content, strength, steel and aluminum, chemical anchor pullout test, compatibility test of sealant, epoxy resin structural adhesive test), four test (water tightness, air tightness, wind pressure, plane deformation etc.)

- Q: The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: What's good with a cup?

- TIPS intimate tips: Mug divided into pure porcelain, porcelain, glass, plastic or stainless steel of these types of materials.

- Q: What materials do we need to make glass septic tanks?

- Advantages of glass reinforced septic tanks:Good impermeability:1., high polymer material as the base material, good sealing, never leak.2. construction speed.3. products for factory production of finished products, site construction is fast, and the high water level, rainy season can also be construction.4. clear long cycle.5., the anaerobic fermentation is sufficient, the silt deposition quantity reduces greatly, the clear cutting cycle prolongs 3-4 times, greatly reduces the follow-up operation and the maintenance cost.6., treatment effect is good.7., set aside bins, hierarchical fermentation, sewage discharged in the BOD, COD and other pollutants significantly reduced.8., small footprint.

- Q: What's the raw material for organic glass fiber reinforced plastic? Thank you.

- Fiber reinforced epoxy resin composites are made from resins (unsaturated polyester resin, alkenyl ester resin, epoxy resin, phenolic resin, etc.) Fiber (glass fiber, carbon fiber, aramid fiber, etc.) Made by special process

- Q: What's the price of 0.85mm thick plexiglass, please?

- Import plate material is better, about 900, but the price is more expensive, generally do not consider adopting, unless their own customers request, and canAt an accepted price.

- Q: What kind of mineral is glass made of?

- Colored glass is made by adding some metal oxides in the manufacture of ordinary glass. Cu2O - red; CuO - blue-green; CdO - pale yellow; CO2O3 - blue; Ni2O3 - dark green; MnO2 - purple; colloidal Au - red; colloidal Ag - yellow)

- Q: The difference between glass wool, rock wool, mineral wool

- 1., raw materials are different: to metallurgical slag or fly ash as the main raw material called slag cotton; basalt and other rock as the main raw material called "rock wool"".2. the coefficient of acidity of rock wool and slag cotton is also different. Rock wool acidity coefficient MK generally greater than 1.5, and even up to more than 2; slag cotton MK generally can only be maintained at around 1.2, it is difficult to more than 1.3.3. because of the difference between chemical composition and acidity coefficient of rock wool and slag cotton, they also show some differences in performance.(1) the difference of water resistance(2) difference of heat resistance;(3) difference in corrosion resistance

- Q: Is the price of glass raw material the biggest proportion of quartz?

- In the long run, quartz is a non renewable energy source, and the trend is rising for a long time.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101 - 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches