Supply the full set of automatic tile equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

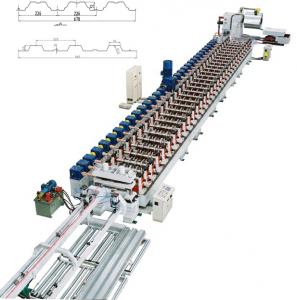

Automatic pressure tile machine is mechanical and electrical control technology used in production to achieve modernization, pressing machinery and equipment program and automation of the production process can tile.Automatic tile function is divided into ceramic tile automatic pressure tile machine, cement tile automatic pressure tile machine, color steel tile automaticpressure tile machine three major categories. Automatic pressure tile machine can be installed using a separate, configurable automatic loading frame andblank unloading manipulator and extrusion machine, cutter consists of tile production lines, do not need to complete the manual operation.

Classification of automatic pressure tile machine

Classification of automatic pressure tile machine:

According to the pressure of raw materials and products of different types oftiles, automatic pressure tile machine accordingly divided into three categories:

(1) ceramic tile automatic pressure tile machine: this kind of pressure tile machine for ceramic tile products production by clay kind of clay as raw material. Products by the repression also need drying, glaze (with or without the glaze) and then by more than 1000 DEG C high temperature sinteringsurface.

(2) cement tile automatic pressure tile machine: this kind of pressure tile machine for cement tile product production to cement sand as raw material.Only after drying and curing paint can.

(3) Caigang watts automatic pressure tile machine: this kind of pressure tile machine with steel sheet metal as raw materials, products need only after forming the painting can.

2 pressure tile machine structure principle

Automatic pressure tile machine of the three kind of different types, the difference between each of the structural principle.

The principle of automatic pressure tile machine structure of 1 ceramic tile

The use of our glazed tile industry automatic pressure tile machine was originally from Germany, Italy, France and other countries the introduction in 2006, Hunan Xiangtan a ceramic machine factory successful automaticpressure tile machine founding production, compared with the importedproducts, for China conditions have improved more in the details. But whether the country

Ceramic glaze tile automatic pressure tile machine

Ceramic glaze tile automatic pressure tile machine

Made or imported automatic pressure tile machine, the basic principle and the structure are roughly the same.

The ceramic tile pressure tile machine is mainly composed of a left, right,bottom, top of the cabinet body connecting rod cap, a sliding seat, six wheel,belt wheel, the gear mechanism, Geneva mechanism, cam mechanism, the lubrication pump, hydraulic system, electric control part and so on. The machine mold punching process: by the motor through the belt pulley, drives the input shaft, the pinion gear on the shaft, big, drive, through a set of cammechanism drives the sliding seat is provided with the upper die of the up and down movement, to achieve pressure tile. Workbench transposition is gear setarranged in the upper end of the shaft by the transmission gear, a shifting pin,a groove wheel mounted on the six party to toggle on a rotating wheel shaft to realize the graduation positioning, at both ends of the upper shaft are respectively provided with a mounted on the same shaft and the back pressing cam conjugate cam, to achieve precise positioning die in the working positionand the positioning plate through the positioning rod. On both sides of the chassis, was installed lubricate pump, through the machine, tubing conveyedto the friction of moving parts of lubricating oil.

Extrusion of mud, the cutting machine cut into fixed length, by a roller conveyor to pressure tile machine, composed of a charging device according to the prescribed procedures, sent to the lower mould, pressed tile in the workbenchtransposition, learn by unloading tile machine vacuum suction, and translocates placed in the conveying line tile holder.

Ceramic tile bench pressure tile machine has six processes (i.e., six runner)workbench turnover, in addition to a level of mechanical dividing, positioning, a precision positioning mechanism is also provided, completely to ensure thatevery time stamping process, accurate positioning working table is installed on the mold, mold slipway is a box body structure, slide to the guide, contactlength, each time stamping die, process of mud has two stamping is the upper die first pressure tile billet in place, the upper die rose 10 mm, so that the mudfully exhaust, mold and then pressing down on the tile billet to a, returned tothe highest position, so the service life of the die is long, pressed products of good quality.

2 cement tile automatic pressure tile machine structure principle and ceramictile automatic tile mechanism is compared, the structure principle of cement tiletile press is relatively simple, which is mainly composed of a hydraulic pump,hydraulic sliding plug, the fixed platen, activity knock table, pressure tile mouldetc.. Its working principle is the current process the raw materials are put into amould, pressure tile mold automatic pressure hydraulic pump drive, cementsand removed more under the pressure of the water to be pressed into denseand has a certain strength of the cement tile products.

Cement tile pressure tile machine

Cement tile pressure tile machine

Early in the production of ceramic tiles in the process also had used this kind of hydraulic press for pressing, but because this kind of models in the blank feeding, demoulding, take tile automation is difficult to adapt to the mud blank,extremely easy to produce deformation, so do not adapt to the automation of ceramic tile industry requirements, only can be applied in semi mechanizedceramic tile.

Tile machine structure principle of automatic pressure 3 color steel tile

The structure principle and cement tile Caigang watts automatic pressure tilemachine automatic pressure tile machine is basically the same. Different is thecolor steel tile pressure tile machine does not need to consider thedeformation of products after pressing and maintenance problems. Therefore,in principle, the requirement is more simple, as long as to achieve certain pressure on it. But compared with the previous two kinds of compressor, theproduct size bigger. So the mechanical equipment appearance has bigger.

3 pressure tile machine main technical parameters for models

4 the equipment installation and commissioning

Installation diagram above the base of all kinds of pressure tile machineequipment must be according to the manufacturers to provide pre installationof equipment, make a concrete foundation, and do the press mounting frame(welding steel) will be placed in to fully cured concrete GUI Based on frame level, a good school, good grouting for two times, to be fully curedbefore installing, press.

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- The position of the embedded parts of the forming machine should be accurate and firm, and the foundation should meet the design requirements and meet the strength of the permitted installation.

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

Supply the full set of automatic tile equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches