High-Quality FRP Roofing Panel - Corrugated Fiberglass Sheets on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

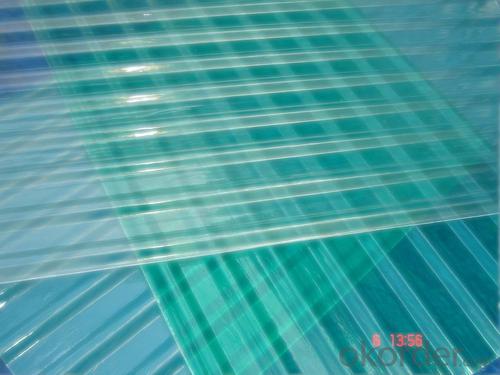

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be used for concert venues?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for concert venues. FRP panels have several qualities that make them suitable for such applications. Firstly, they are lightweight, which makes them easier to install and reduces the load on the structure. This can be particularly important for concert venues with large roof spans. Secondly, FRP panels are highly durable and have a long lifespan. They are resistant to corrosion, weathering, and UV radiation, ensuring that they can withstand the outdoor elements and the wear and tear associated with concert venues. This durability also translates into cost savings, as the panels require minimal maintenance and replacement. Furthermore, FRP panels offer excellent light transmission capabilities, allowing natural light to filter through the roof. This can create a more pleasant and visually appealing atmosphere for concert-goers during daytime events. Additionally, FRP panels come in a variety of color options, allowing for customization to match the aesthetic requirements of the concert venue. They can be translucent or opaque, depending on the desired level of light transmission and privacy. Overall, FRP roofing panels are a versatile and practical choice for concert venues, providing durability, light transmission, and ease of installation.

- Q: Do FRP roofing panels provide sound insulation?

- No, FRP roofing panels do not provide sound insulation.

- Q: Can FRP roofing panels be used for shopping malls?

- Shopping malls can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are not only durable and versatile but also offer numerous advantages. They are lightweight, simplifying installation and decreasing structural load. Additionally, FRP panels provide excellent protection against UV rays, rain, and extreme temperatures, making them highly weather-resistant. When it comes to shopping malls, FRP roofing panels can prove to be a cost-effective solution due to their minimal maintenance requirements and long lifespan. By allowing natural light transmission, they can reduce the necessity for excessive artificial lighting during daylight hours, potentially lowering energy expenses. Moreover, FRP roofing panels come in a variety of colors and finishes, enabling customization to align with the shopping mall's aesthetic requirements. They can also be manufactured to offer thermal insulation, contributing to both energy efficiency and occupant comfort. In summary, FRP roofing panels present a suitable choice for shopping malls due to their durability, weather resistance, cost-effectiveness, and design flexibility.

- Q: Are FRP roofing panels resistant to UV radiation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to UV radiation. FRP panels are manufactured using a combination of fiberglass and plastic resin, which provide them with excellent durability and resistance to various environmental factors, including UV radiation. The panels are typically coated with a protective layer that further enhances their UV resistance. This UV-resistant coating prevents the panels from becoming brittle or discolored over time due to prolonged exposure to the sun's ultraviolet rays. Overall, FRP roofing panels are designed to withstand the effects of UV radiation and maintain their structural integrity and aesthetic appearance for an extended period.

- Q: Can FRP roofing panels be installed on both residential and commercial train stations?

- FRP roofing panels are suitable for installation on both residential and commercial train stations. These panels are lightweight, durable, and possess excellent weather resistance, making them suitable for a variety of uses. Whether it is a small residential station or a large commercial one, FRP roofing panels offer dependable defense against the elements while maintaining an appealing look. Moreover, the installation of FRP panels is effortless and their maintenance requirements are minimal, making them a cost-effective and sensible option for train stations, regardless of their nature.

- Q: Do FRP roofing panels require a specific type of edge trim?

- No, FRP (Fiberglass Reinforced Plastic) roofing panels do not necessarily require a specific type of edge trim. However, it is recommended to use a compatible trim that complements the FRP panels and provides a secure and aesthetically pleasing finish. The type of edge trim needed may depend on various factors including the specific design and installation requirements of the roofing system, the type and thickness of the FRP panels, and the specific climate and environmental conditions. It is advisable to consult with the manufacturer or a roofing professional to determine the most suitable edge trim for your FRP roofing panels.

- Q: Are FRP roofing panels resistant to graffiti?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are resistant to graffiti. The smooth surface of FRP panels makes it difficult for graffiti to adhere, and even if it does, it can be easily removed without causing any permanent damage to the panel.

- Q: Are FRP roofing panels resistant to chemical fumes?

- Yes, FRP roofing panels are generally resistant to chemical fumes. The fiberglass reinforced plastic used in their construction provides excellent resistance to a wide range of chemical substances, making them a suitable choice for environments where chemical fumes may be present. However, it is always recommended to consult the manufacturer's specifications and guidelines for specific chemical resistance information.

- Q: Can FRP roofing panels be used for concert venues?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for concert venues. FRP panels have several qualities that make them suitable for such applications. Firstly, they are lightweight, which makes them easier to install and reduces the load on the structure. This can be particularly important for concert venues with large roof spans. Secondly, FRP panels are highly durable and have a long lifespan. They are resistant to corrosion, weathering, and UV radiation, ensuring that they can withstand the outdoor elements and the wear and tear associated with concert venues. This durability also translates into cost savings, as the panels require minimal maintenance and replacement. Furthermore, FRP panels offer excellent light transmission capabilities, allowing natural light to filter through the roof. This can create a more pleasant and visually appealing atmosphere for concert-goers during daytime events. Additionally, FRP panels come in a variety of color options, allowing for customization to match the aesthetic requirements of the concert venue. They can be translucent or opaque, depending on the desired level of light transmission and privacy. Overall, FRP roofing panels are a versatile and practical choice for concert venues, providing durability, light transmission, and ease of installation.

- Q: Are FRP roofing panels resistant to vandalism or graffiti?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, offer a certain level of resistance to vandalism and graffiti. While they are generally more resistant compared to other roofing materials like metal or asphalt, they are not completely immune to such acts. The smooth surface of FRP roofing panels makes it more difficult for vandals to spray paint or draw graffiti on them. Additionally, the panels are typically made of durable materials that can withstand impact and scratching to some extent. This makes it harder for individuals to damage or deface the panels deliberately. However, it is important to note that FRP roofing panels can still be susceptible to vandalism and graffiti, especially if targeted by determined individuals. Certain factors, such as the location of the panels and the level of security in the area, can also influence the likelihood of such incidents occurring. To enhance the resistance of FRP roofing panels to vandalism or graffiti, additional measures can be taken. For instance, applying an anti-graffiti coating or film on the surface of the panels can act as a protective barrier, making it easier to remove any unwanted markings. Surveillance systems and proper lighting in the vicinity of the panels can also deter vandals. In conclusion, while FRP roofing panels offer a certain degree of resistance to vandalism and graffiti due to their smooth surface and durable materials, it is not guaranteed that they will remain completely unscathed. Taking appropriate preventive measures and implementing security measures can further enhance their resistance to such acts.

Send your message to us

High-Quality FRP Roofing Panel - Corrugated Fiberglass Sheets on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords